Roller press hydraulic system and automatic pressure stabilizing device thereof

A technology of hydraulic system and automatic voltage stabilization, applied in grain processing and other directions, can solve the problems of affecting the output of the system, unstable pressure, poor extrusion effect, etc., achieving the effect of simple overall structure, solving pressure fluctuations, and enhancing extrusion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

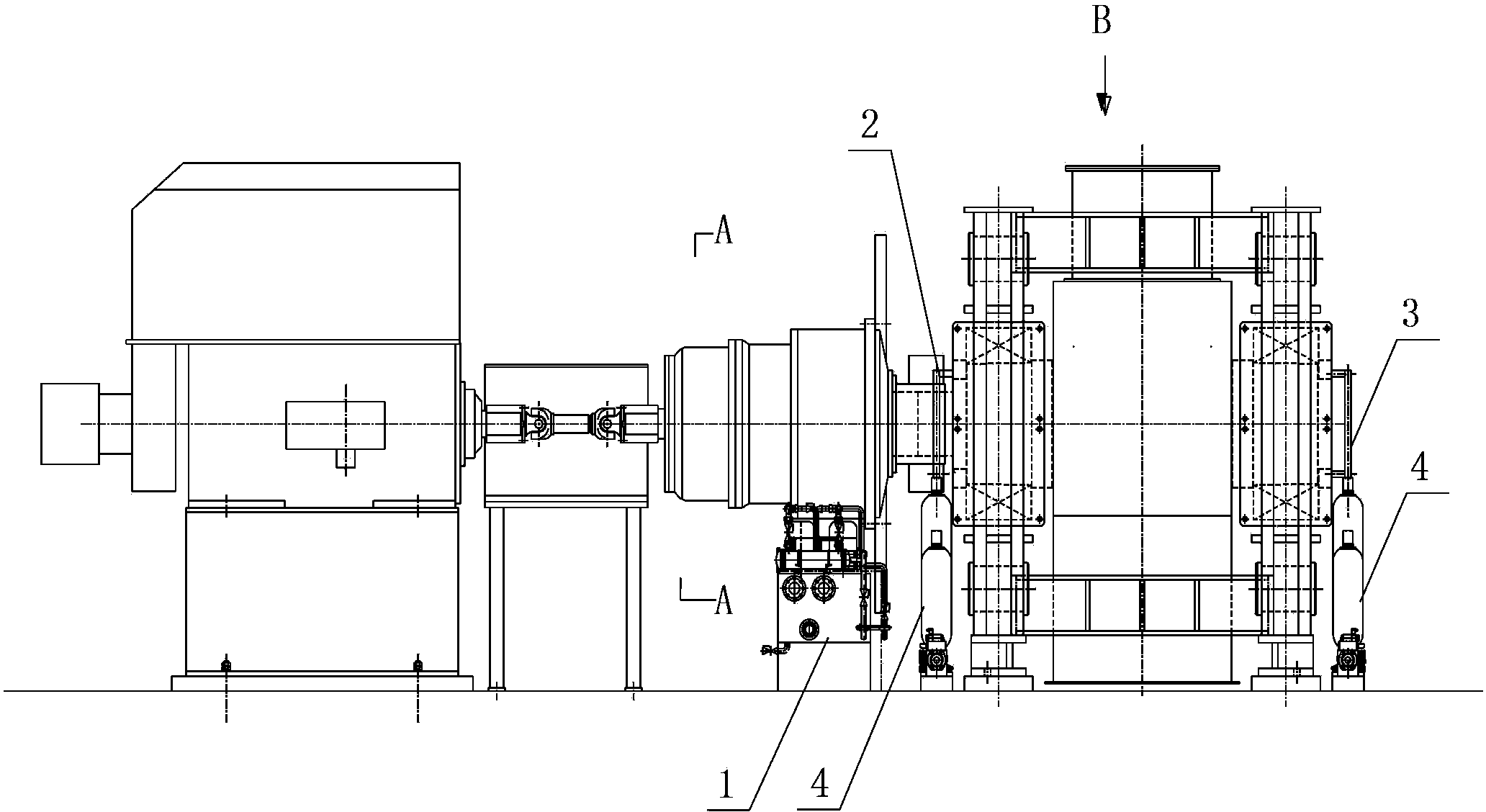

[0019] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0020] The first embodiment provided by the present invention is an automatic pressure stabilizing device for the hydraulic system of a roller press. According to the actual function of the present invention, it is generally installed near the hydraulic system of a roller press.

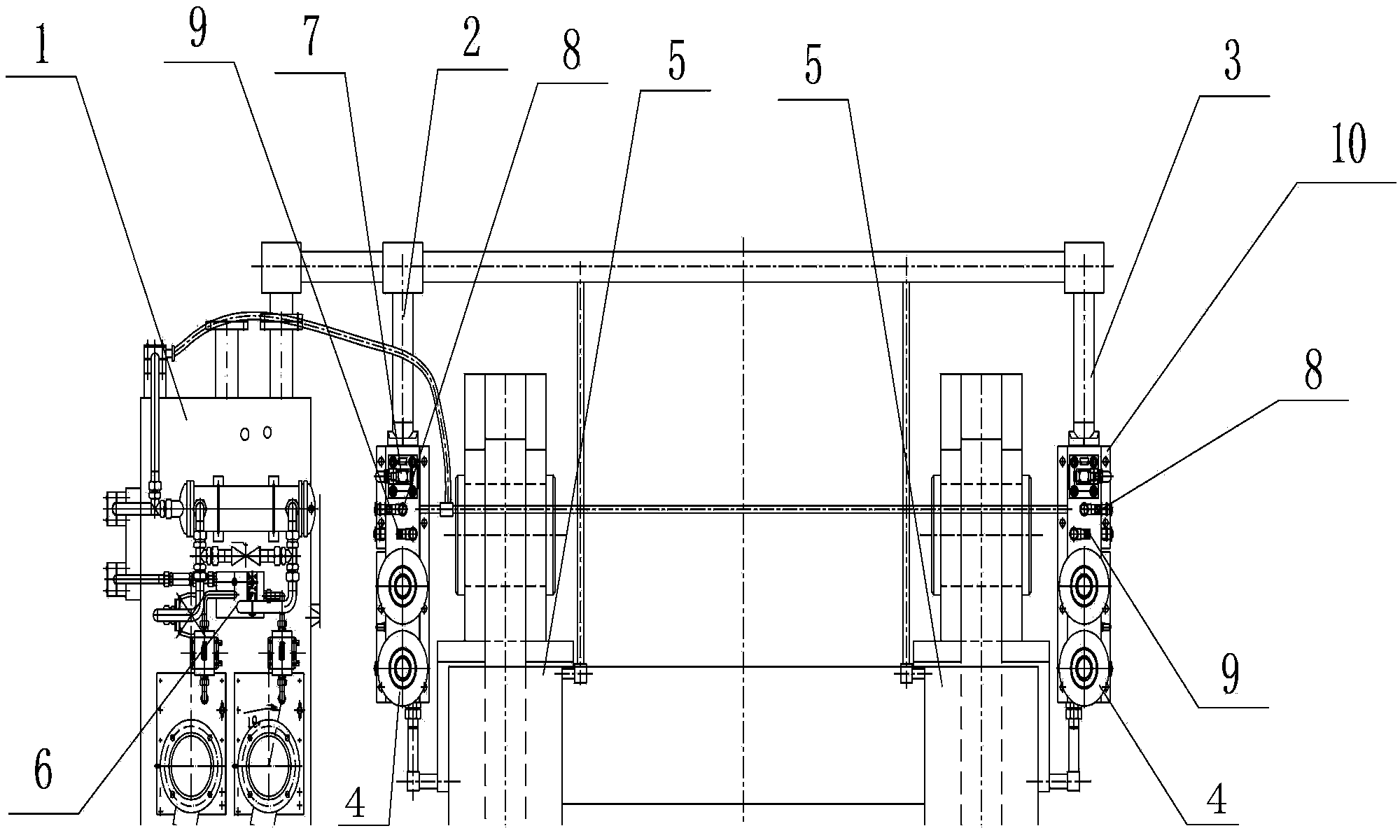

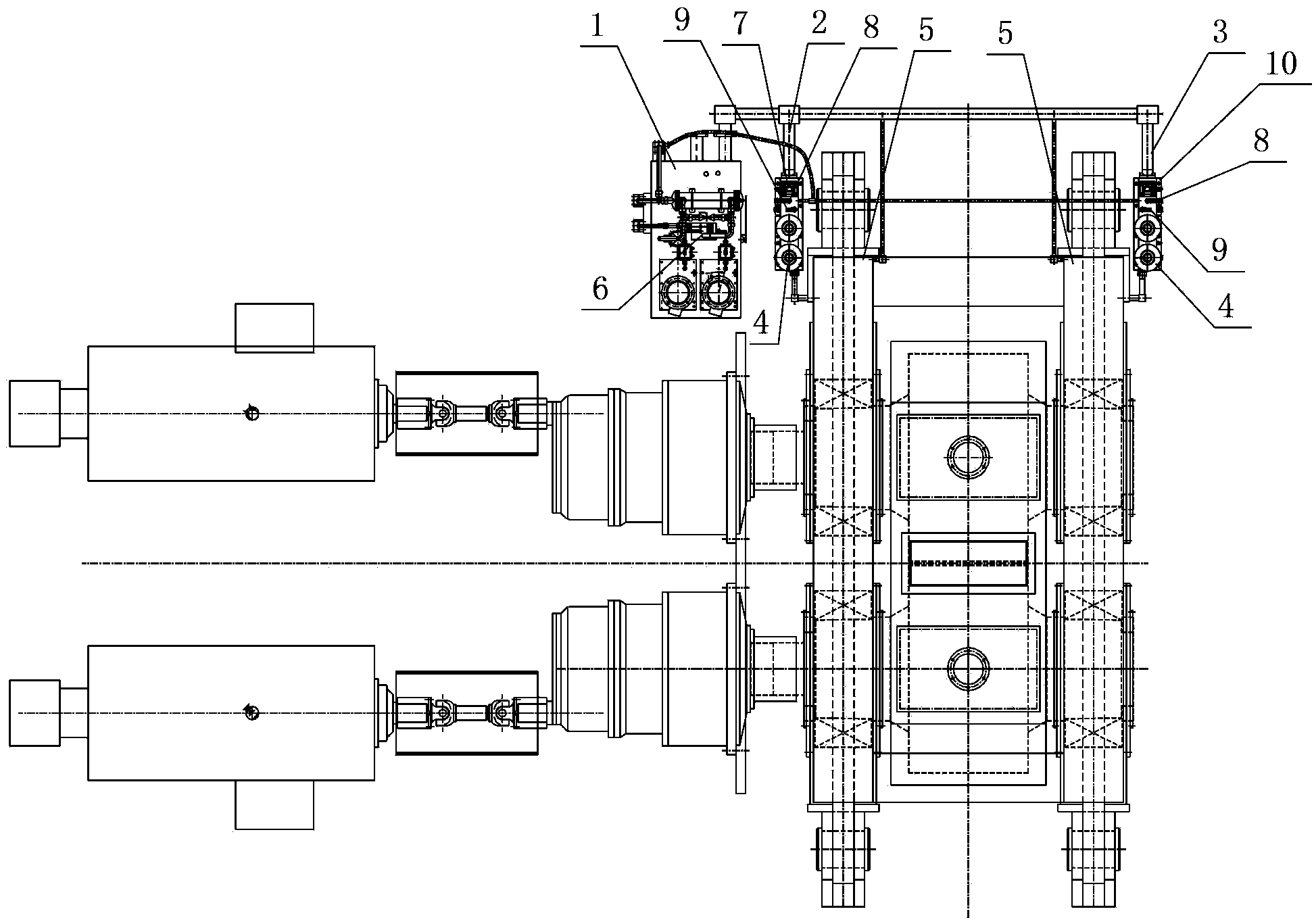

[0021] refer to figure 1 As shown, the automatic voltage stabilizing device includes a hydraulic oil station 1, a left voltage stabilizing device 2 and a right voltage stabilizing device 3, and the left voltage stabilizing device 2 and the right voltage stabilizing device 3 are all provided with The accumulator 4 communicates with the combined valve body, the left pressure stabilizing device 2 and the accumulator 4 in the right voltage stabilizing device 3 respectively through pipelines and the oil cylinder working chamber 5 on both sides of the hydraulic system of the roller press, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com