Double-air compartment multifunctional winnowing machine used for municipal solid waste

A municipal solid waste, multi-functional technology, applied in the field of municipal solid waste treatment, can solve the problems of untreated or recycled waste gas, inaccurate movement trajectory research, unreasonable structure of the sorter, etc. Wind selection accuracy, the effect of ensuring purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

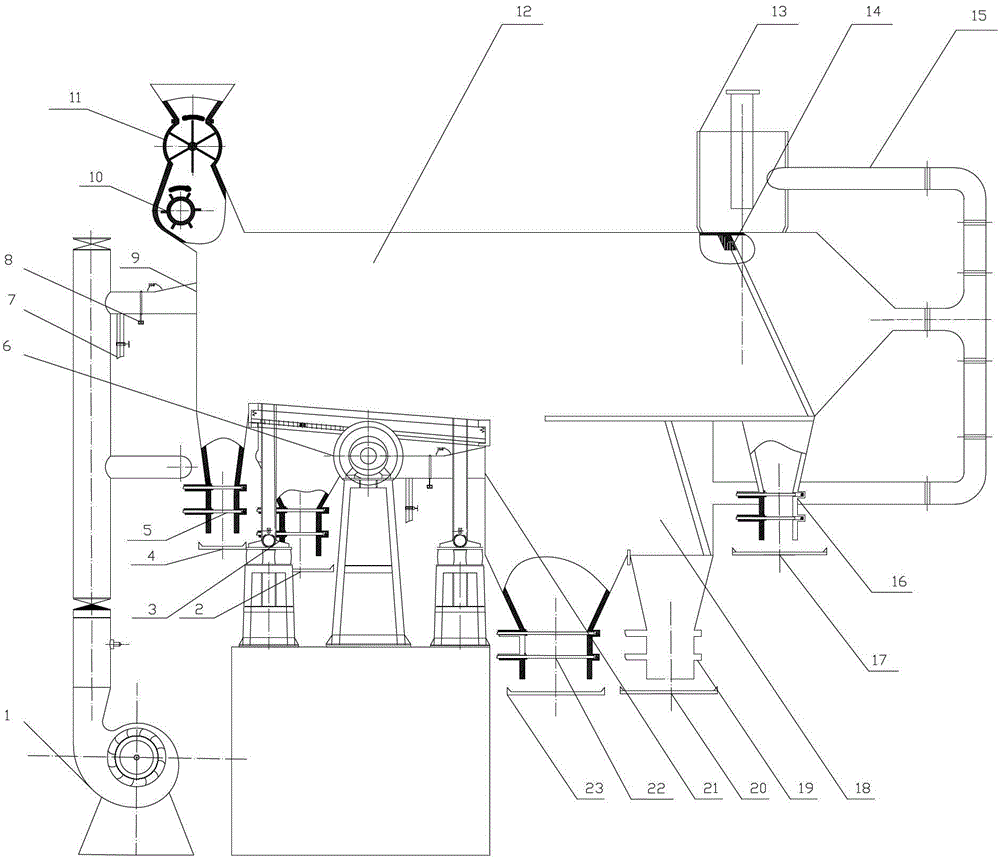

[0031] Such as Figure 1 to Figure 4As shown, it is a schematic diagram of a double-air chamber multifunctional winnowing machine for municipal solid waste in the present invention. Municipal solid waste enters the rotary feed air locker 11, and the rotating blades of the rotary feed locker 11 and the winnowing machine The shell of the wind separator is airtightly matched to prevent the gas in the winnowing machine from running out of the rotary feed air locker 11; the municipal solid waste falls evenly under the rotation of the rotating blades of the rotary feed air locker 11 and passes through the breaking drum 10 Break up; enter the first winnowing chamber 12, the blower group 1 communicates with the first wind chamber air inlet 9 on the top of the first winnowing chamber 12 through the pipeline, and the rubbish is blown in by the wind blown by the blower group 1 in the first winnowing chamber 12. The first sorting is carried out by blowing, and the plastic paper and heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com