Tool rest

A tool holder and cutter head technology, applied in the direction of tool holders, etc., can solve the problems of high matching accuracy, inability to apply synchronous processing, and complicated tool holder assembly structure, so as to improve processing efficiency, save replacement time, and facilitate assembly and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

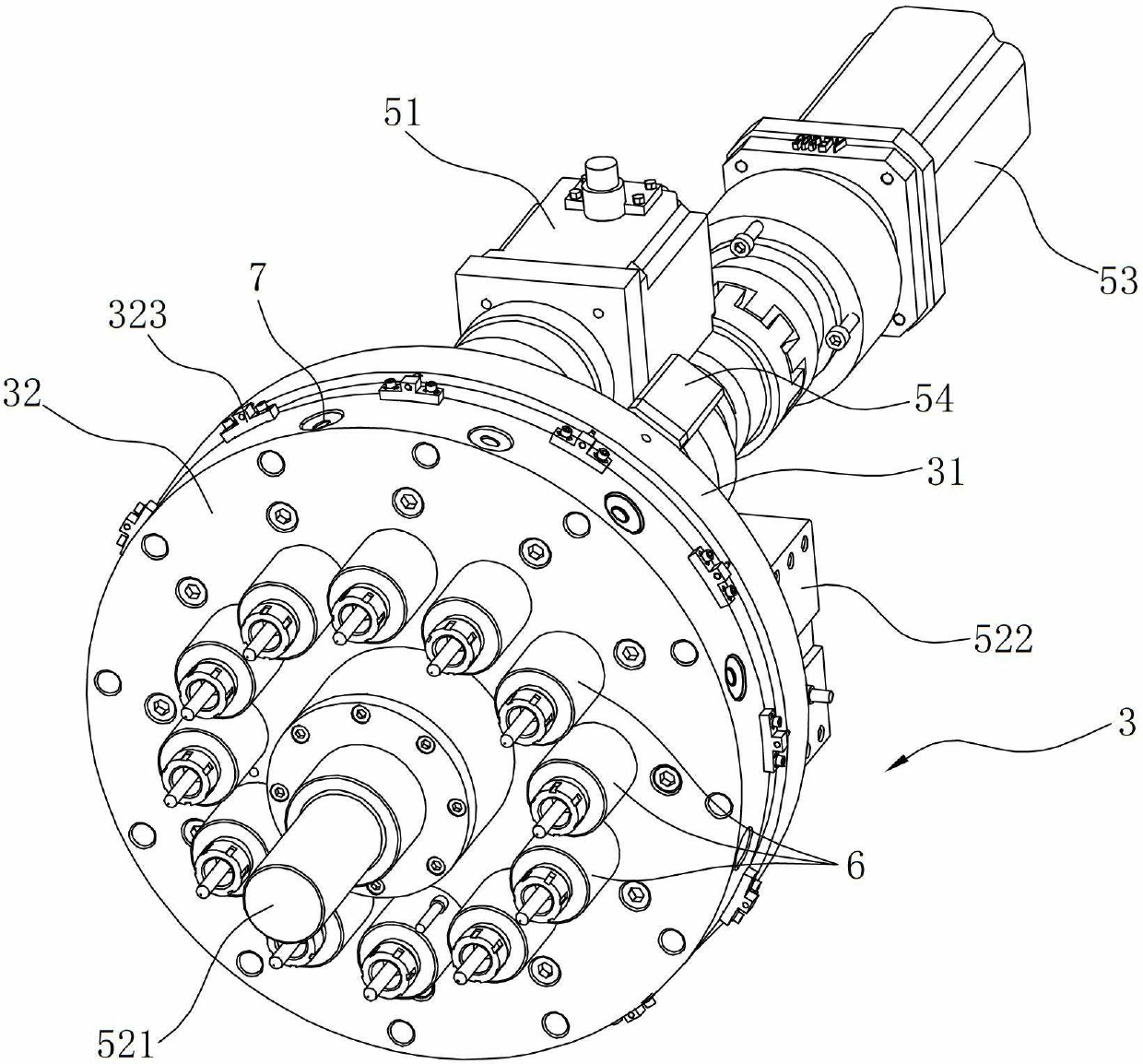

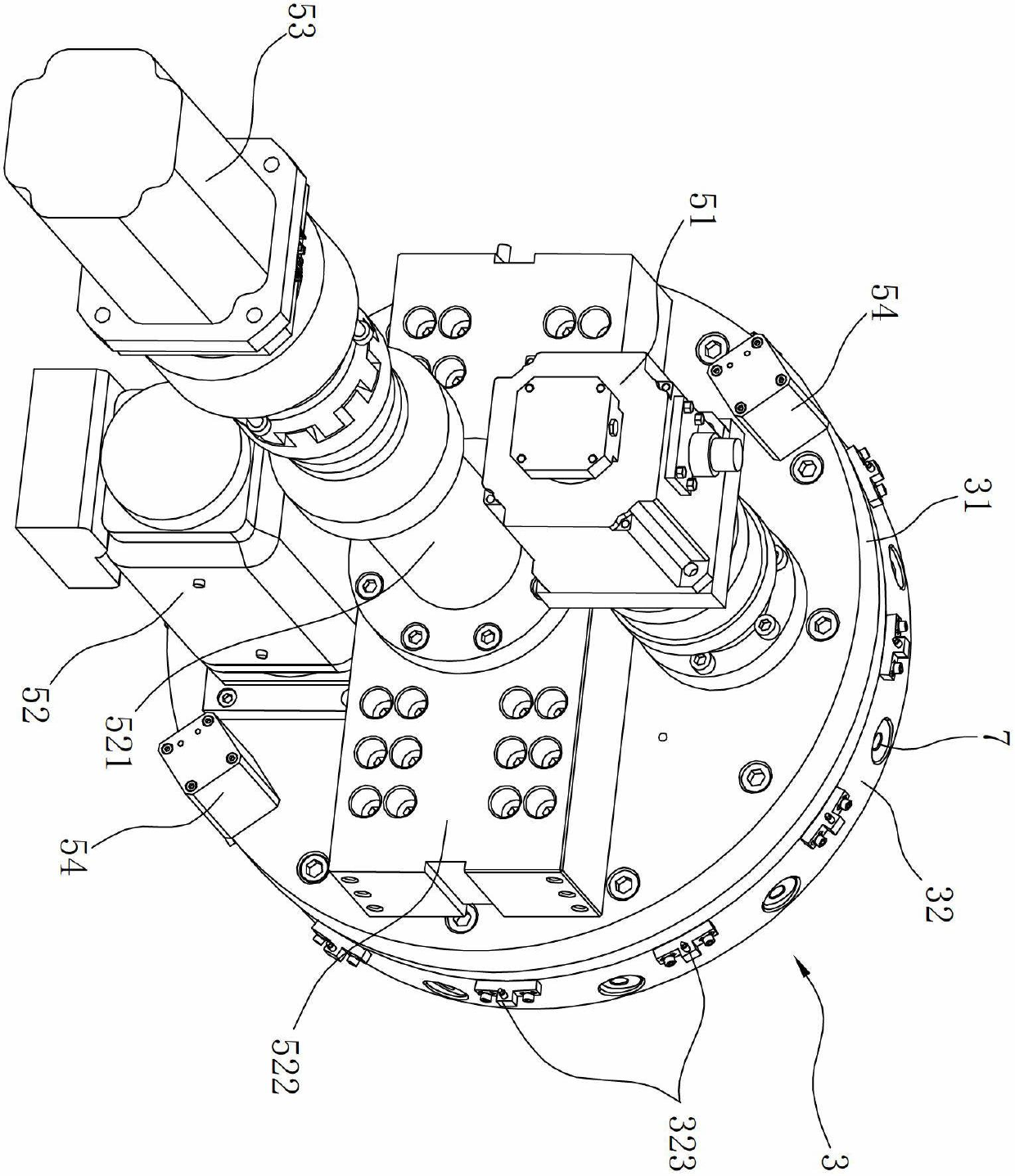

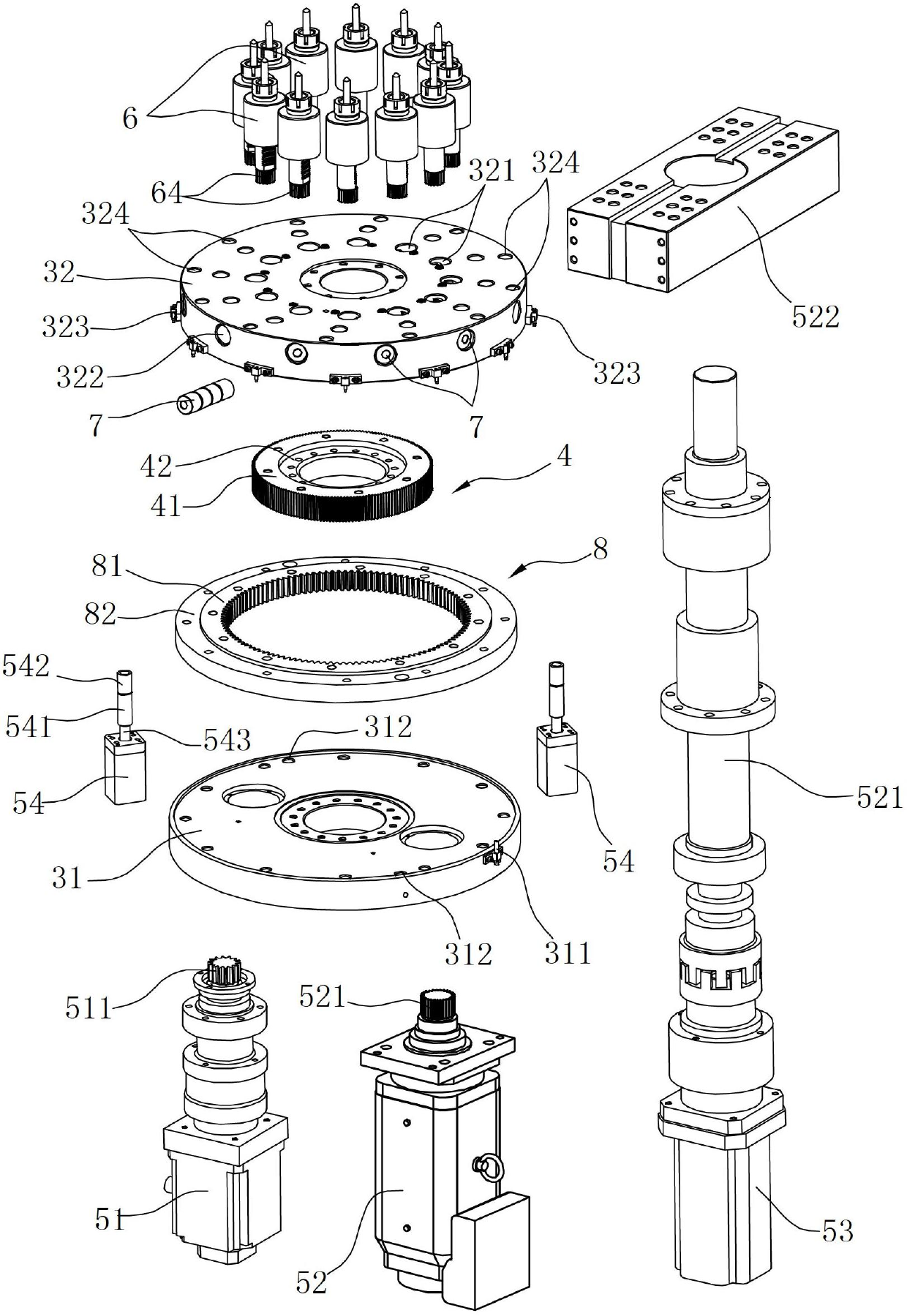

[0024] Such as Figure 1 to Figure 7 As shown, this embodiment is a tool rest 3 installed on the machine base of the pipe end processing equipment. The tool rest 3 adopts a turret structure, which includes a vertically arranged fixing plate 31 and is rotatably connected to the The cutter head 32 on the fixed plate 31 is equipped with a plurality of cutters 6 for processing the end face of the pipe fittings along the circumference of the cutter head 32, and the tool holder 3 is also provided with a drive tool holder 3 along the direction approaching or away from the workbench. The main driving device for linear motion, the main driving device includes a third motor 53, a screw shaft 521 and a push plate 522, the tool rest 3 is provided with an axial hole for the screw shaft 521 to pass through in the axial direction, and the push plate 522 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com