A kind of preparation method of workpiece

A technology of prefabricated parts and composite parts, which is applied in the direction of chemical instruments and methods, digital data processing parts, instruments, etc., can solve problems such as prone to waste products, unfavorable spraying, and inability to achieve appearance effects, so as to achieve good use effects and realize software tactile effect, effect of improving appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] An embodiment of the present invention provides a method for preparing a workpiece, which is characterized in that it includes:

[0047] a) Provide metal / plastic composite parts;

[0048] b) preparing a polyurethane layer on the surface of the metal / plastic composite to obtain a workpiece.

[0049] According to an embodiment of the present invention, the metal / plastic composite part is formed by compounding a metal part and a plastic part, a typical metal composite part such as a cover of a notebook, but not limited thereto. The material of the metal parts is preferably magnesium-aluminum alloy, which has low density and high strength, so while ensuring that the notebook is light and thin, it is also guaranteed to have good strength. In order to prevent the magnesium-aluminum alloy from shielding the antenna signal in the notebook, the part corresponding to the antenna is combined with a plastic part and a metal part. Specific examples of the material of the plastic pa...

Embodiment 1

[0070] Plastic raw material composition: Japan Sumitomo E4008;

[0071] Polyurethane raw material composition: DuPont IMRON2.8HGTM, divided into A component and B component, wherein A component is isocyanate, B component is polyol and catalyst.

[0072] The operation steps are as follows:

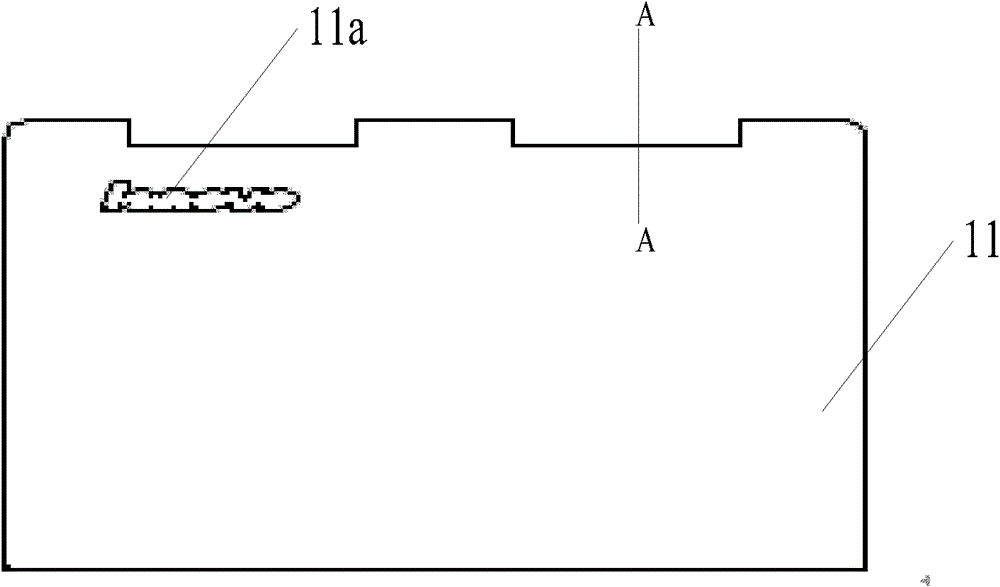

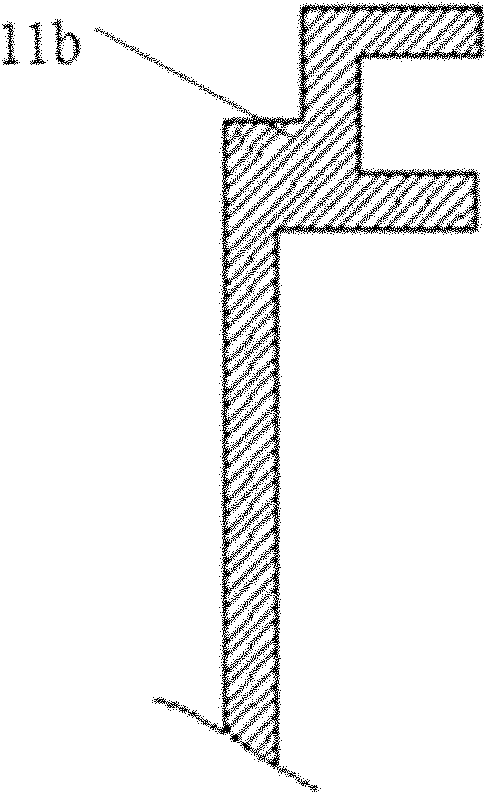

[0073] The metal preform 11 made of magnesium-aluminum alloy is obtained by die-casting, and then the position 11a of the antenna cover is processed on the metal preform, such as figure 2 Shown is the front view of the metal prefabricated part; image 3 for figure 2 In the cross-sectional view of the workpiece along A-A, the upper end surface 11b of the metal part 11 is used to contact the plastic part;

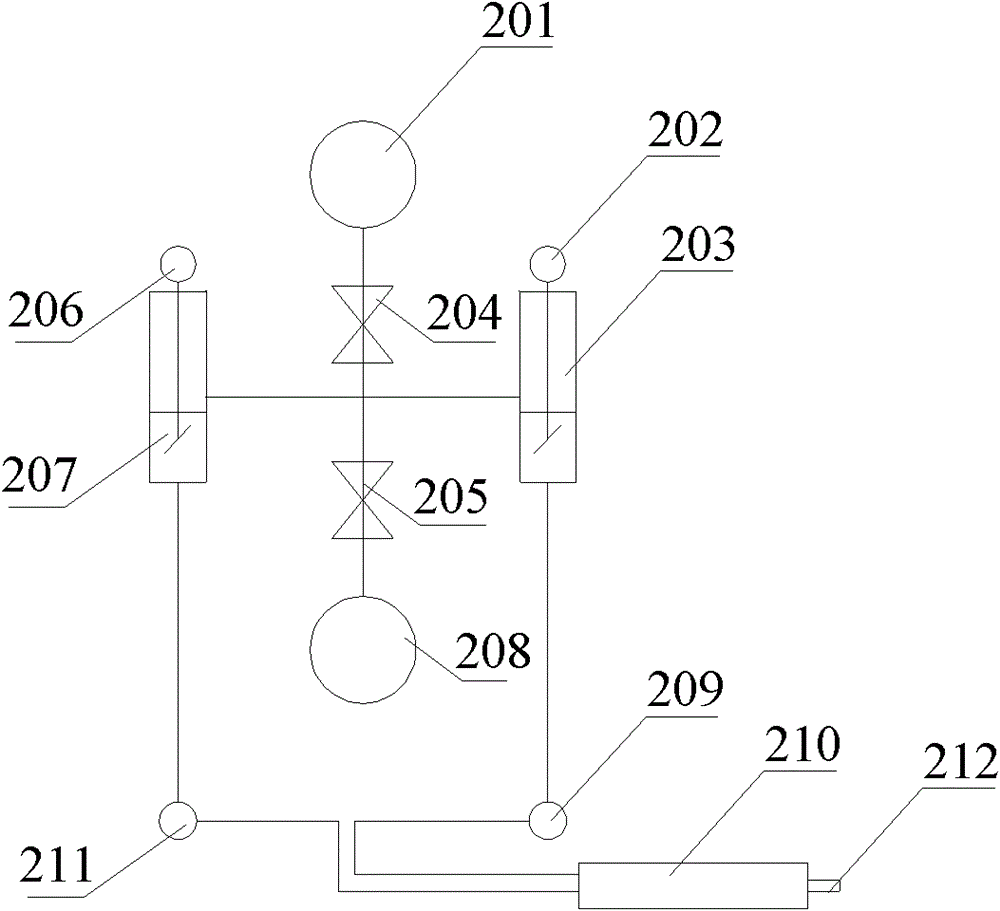

[0074] See Figure 4 , is a schematic diagram of the molding die 21 used in the method of this embodiment, and the molding die 21 includes a first cavity 21a for molding a metal / plastic composite and a second mold for molding a polyurethane layer on the surface of the composite Cave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com