Method for preparing densely compacted negative electrode material for lithium-ion battery

A technology for lithium-ion batteries and negative electrode materials, which is applied in the field of electrochemistry and can solve problems such as limited improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

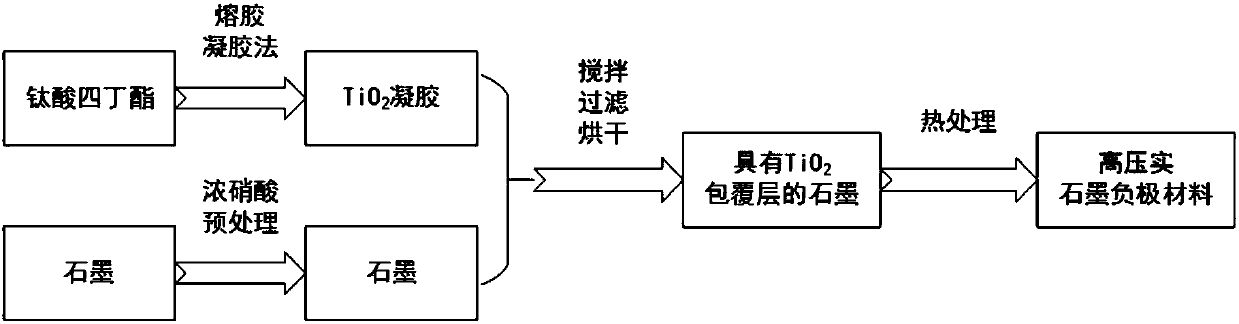

[0021] refer to figure 1 , the invention provides a kind of method for preparing lithium-ion battery high-pressure negative electrode material, comprises the following steps:

[0022] (1) At room temperature, slowly add tetrabutyl titanate to absolute ethanol at a volume ratio of 1:5. After the addition is complete, stir vigorously for 10-20 minutes;

[0023] (2) Mix glacial acetic acid, distilled water, and absolute ethanol in a volume ratio of 4:10:35, and stir vigorously;

[0024] (3) Slowly add the solution obtained in step (1) to the solution obtained in step (2) under vigorous stirring. After the addition is complete, continue stirring for 30 minutes, and then heat in a water bath for 2 hours;

[0025] (4) boil the natural graphite particles with a medium particle size of 15 μm in 60% concentrated nitric acid for 24 hours, and repeatedly wash with ethanol and distilled water successively, and then dry;

[0026] (5) Add the product of step (4) to the sol obtained in ste...

Embodiment 2

[0029] (1) At room temperature, slowly add tetrabutyl titanate to absolute ethanol, according to the volume ratio of 1:12, after the addition is completed, vigorously stir for 10-20 minutes;

[0030] (2) Mix glacial acetic acid, distilled water, and absolute ethanol in a volume ratio of 4:10:35, and stir vigorously;

[0031] (3) Slowly add the solution obtained in step (1) to the solution obtained in step (2) under vigorous stirring. After the addition is complete, continue stirring for 30 minutes, and then heat in a water bath for 2 hours;

[0032] (4) boil the natural graphite particles with a medium particle size of 15 μm in 60% concentrated nitric acid for 24 hours, and repeatedly wash with ethanol and distilled water successively, and then dry;

[0033] (5) Add the product of step (4) to the sol obtained in step (3), fully stir until uniform, filter, and dry;

[0034] (6) The product obtained in step 4 is heat-treated at 500-800° C. for 12 hours under an inert atmosphere...

Embodiment 3

[0036] (1) At room temperature, slowly add tetrabutyl titanate to absolute ethanol at a volume ratio of 1:5. After the addition is complete, stir vigorously for 10-20 minutes;

[0037] (2) Mix glacial acetic acid, distilled water, and absolute ethanol in a volume ratio of 4:15:35, and stir vigorously;

[0038] (3) Slowly add the solution obtained in step (1) to the solution obtained in step (2) under vigorous stirring. After the addition is complete, continue stirring for 30 minutes, and then heat in a water bath for 2 hours;

[0039] (4) boil the natural graphite particles with a medium particle size of 15 μm in 60% concentrated nitric acid for 24 hours, and repeatedly wash with ethanol and distilled water successively, and then dry;

[0040] (5) Add the product of step (4) to the sol obtained in step (3), fully stir until uniform, filter, and dry;

[0041] (6) The product obtained in step 4 is heat-treated at 500-800° C. for 12 hours under an inert atmosphere to obtain a ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com