Method and device for modifying high-polymer materials through hot gas and ultrasonic wave

A polymer material, ultrasonic technology, applied in the field of polymer material modification, can solve the problem of active regulation of the components of the substrate without molecular chains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

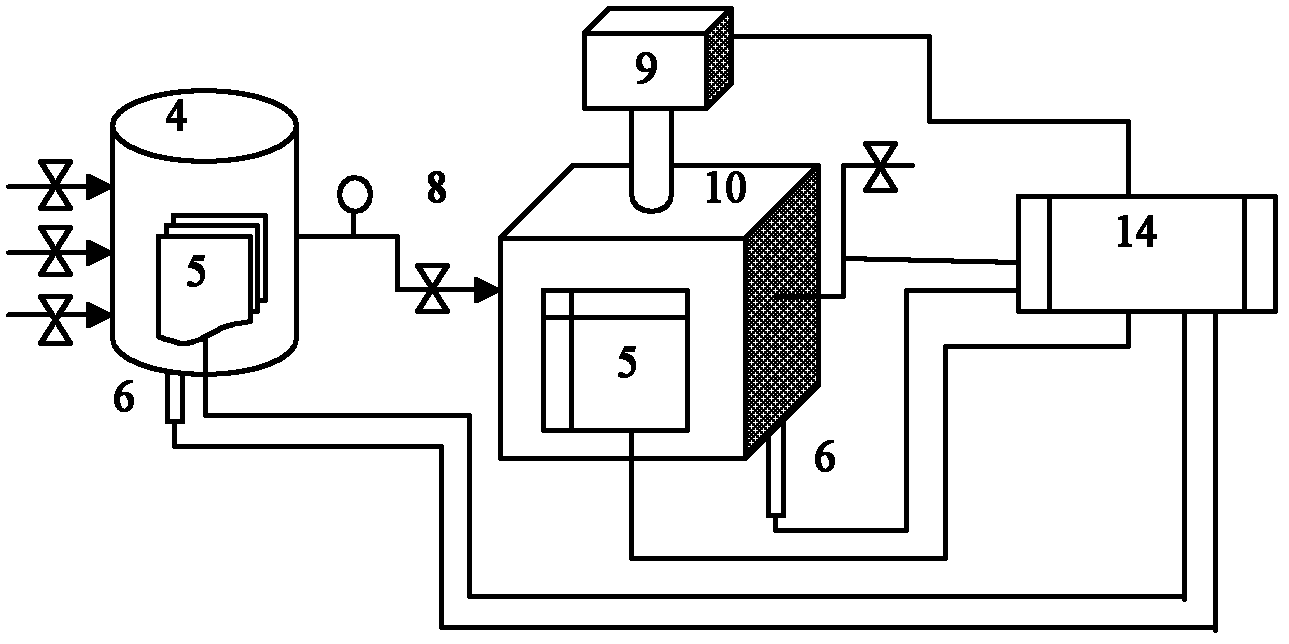

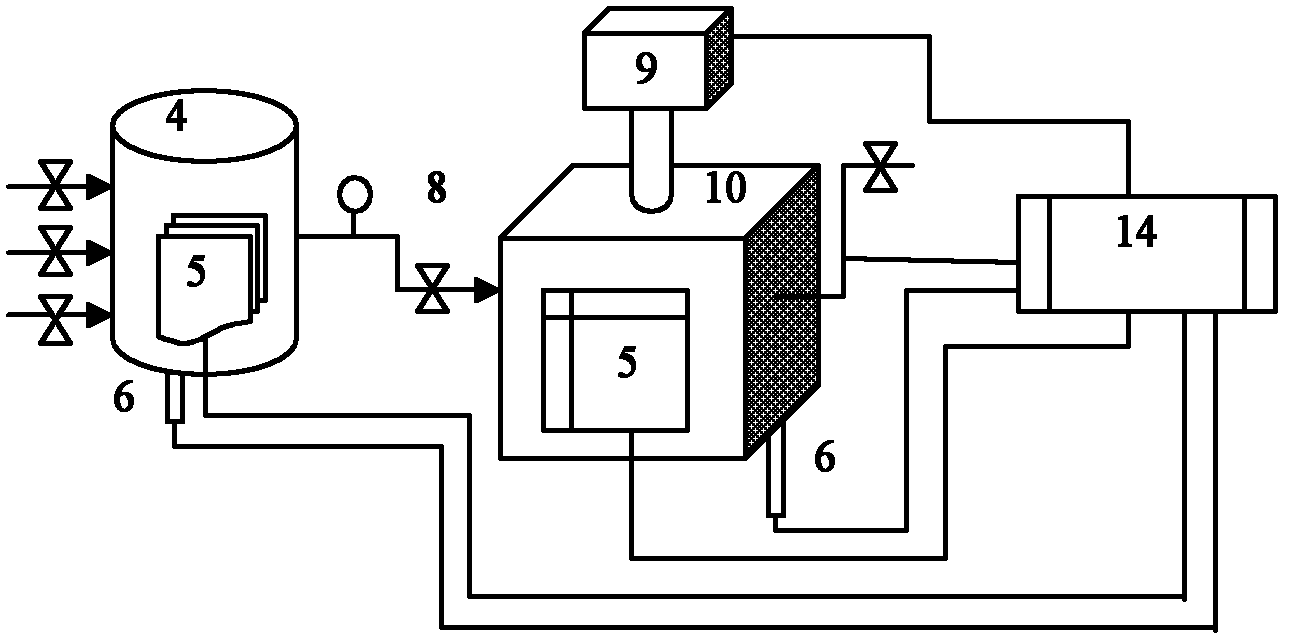

[0026] Surface hardening of injection molded products. Take the high-density polyethylene injection molding standard sample (no shape and size requirements, just put it down) and place it in the cavity 10 of the ultrasonic processing device, and pass the argon gas into the cavity 10 of the ultrasonic processing device from the gas mixing chamber 4 , under the condition of gas pressure 0.15Mpa, raise the temperature and keep the constant temperature to 55°C for 5 minutes, and start while maintaining (it can also be started after the temperature is maintained, which has little effect on the results, the same as in the following examples 2 and 3) Ultrasonic is used for sample processing, the processing time is 20min, the ultrasonic frequency is 40KHz, and the power is 200w.

[0027] After treatment, the surface hardness of the samples increased by an average of 5%.

Embodiment 2

[0029] The surface group conformation changes. Take the protein film and place it in the cavity 10 of the ultrasonic processing device. The ethanol is vaporized in the gas mixing chamber 4, and then passed into the cavity 10 of the ultrasonic processing device to form a gas with a pressure of 0.15 MPa and a temperature of 80 ° C. The temperature is kept constant for 5 minutes. Simultaneously start the ultrasonic treatment for 15 minutes, the ultrasonic frequency is 20KHz, and the power is 100w.

[0030] After the treatment, ethanol was removed in vacuo, and the surface of the sample changed from hydrophobic to hydrophilic.

Embodiment 3

[0032] The aggregate structure changes. The glass fiber reinforced PP material spline is placed in the processing cavity, and the N 2 The gas is formed in the gas mixing chamber 4, and then passed into the cavity 10 of the ultrasonic processing device. The gas pressure is 0.2Mpa, the temperature is 65°C, and the temperature is kept constant for 10 minutes. At the same time, the ultrasonic processing device is started at the constant temperature, and the ultrasonic treatment is performed for 15 minutes. The ultrasonic frequency is 40KHz, and the power 200w.

[0033] After treatment, the average tensile strength of the sample can be increased by 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com