Novel broad-breadth sun-shading material and preparation method thereof

A wide and new technology, applied in the field of new wide sunshade materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

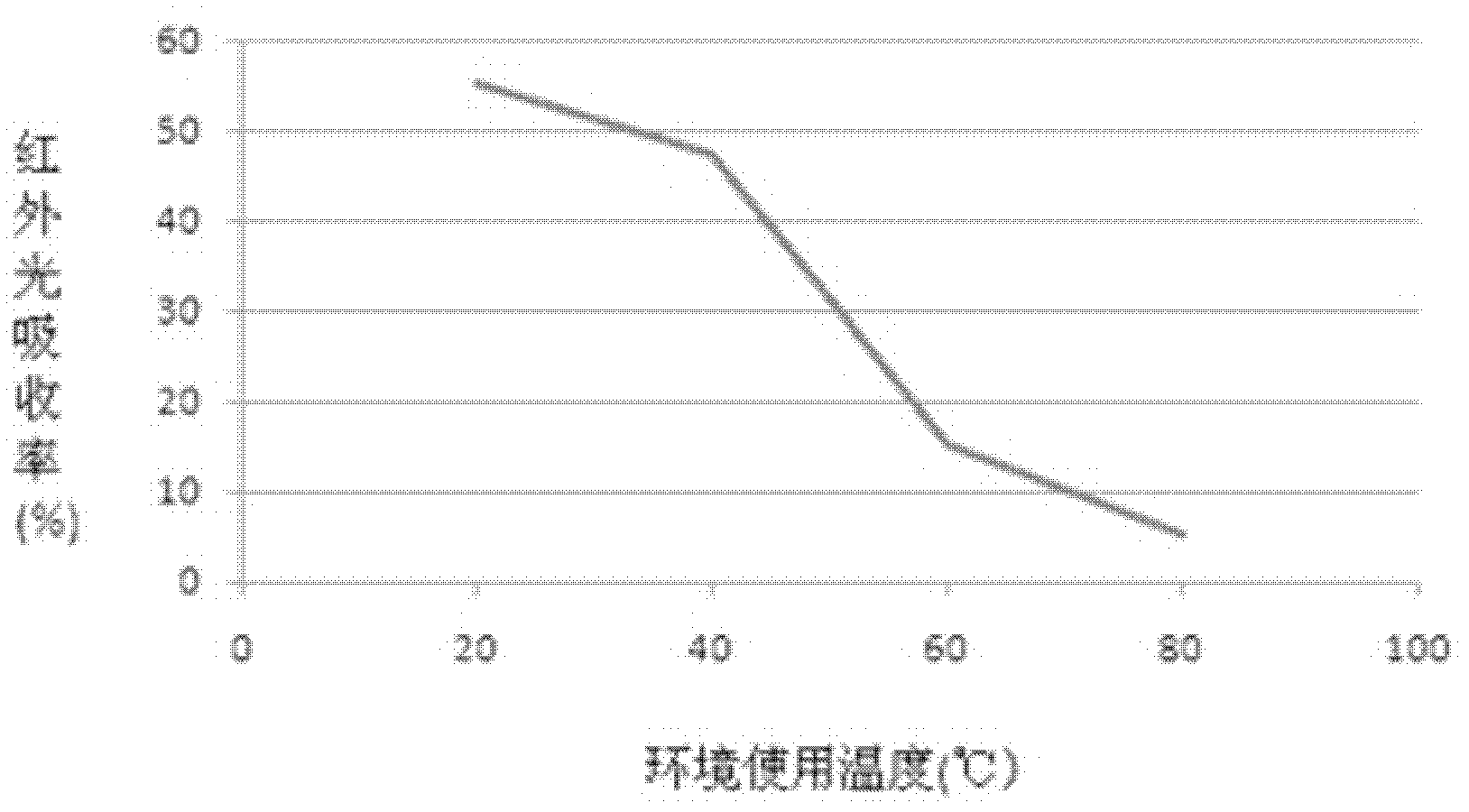

Problems solved by technology

Method used

Image

Examples

Embodiment 1

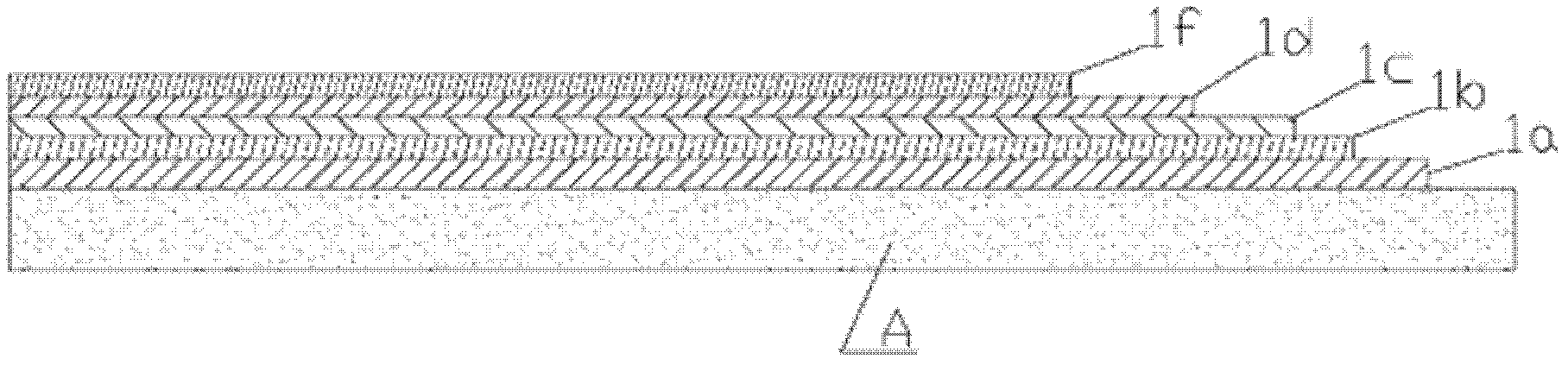

[0024] Example 1: Al 2 o 3 / Ag / Al 2 o 3 / VO 2 .W / Al 2 o 3 Film Preparation Method

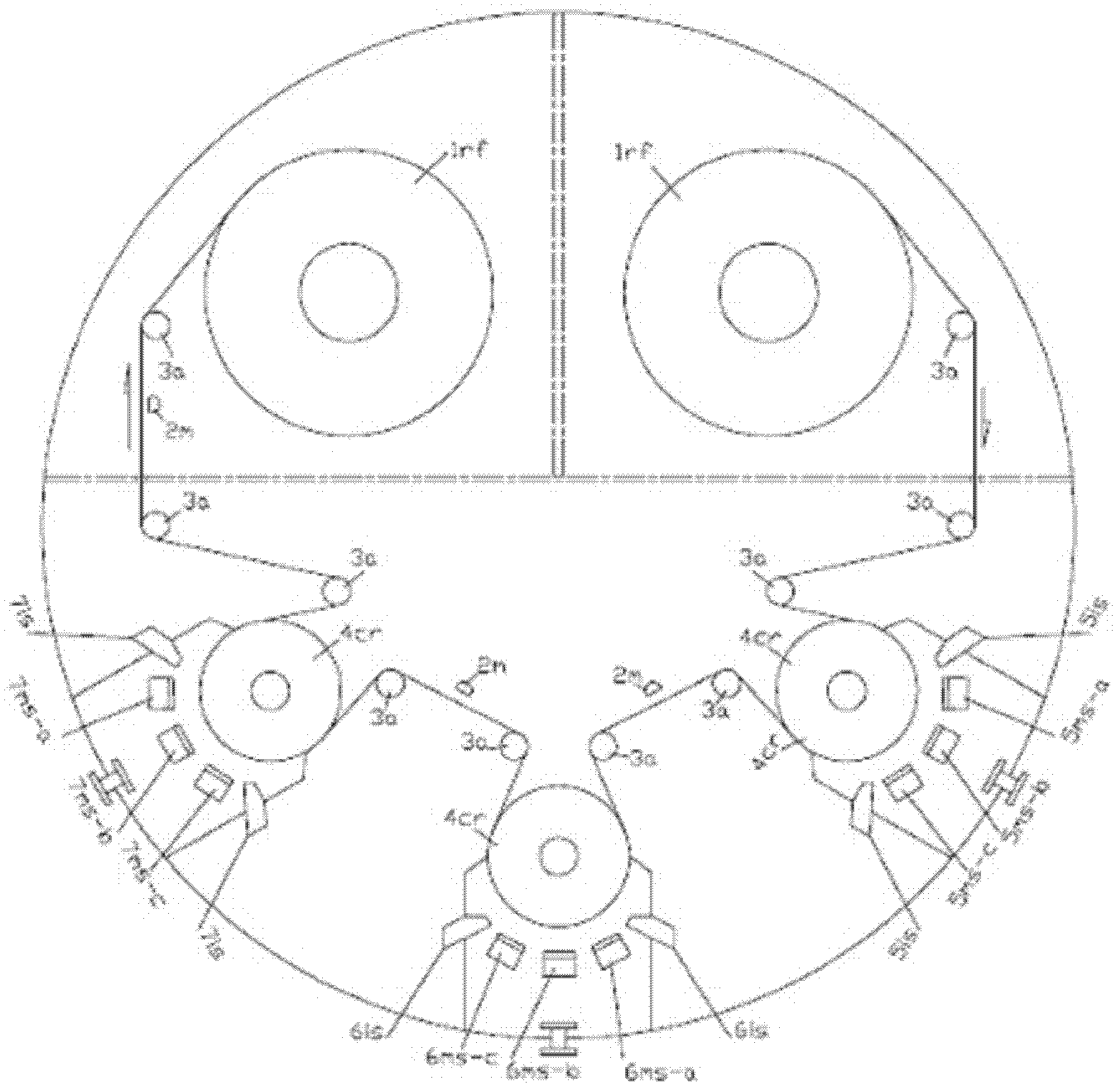

[0025] The optical PET film roll material with a thickness of 8um and a width of 1000mm is used as the substrate material A, and enters the reaction chamber of the magnetron sputtering device smoothly and continuously through a set of tension control guide rollers 3a, and the deposition surface of the substrate is placed downward, which can effectively To prevent granular impurities from contaminating the substrate surface, the reaction chamber is vacuumed to 2×10 -3 Pa, at Figure II The medium 5ms-a target uses 99.99% alumina ceramics as the target material, Ar as the sputtering gas and pure O 2 As an auxiliary ion-enhanced gas input reaction chamber, transparent Al was deposited by DC reactive magnetron sputtering 2 o 3 Floor. Sputtering / reaction enhancing gas flow ratio Ar:O 2 =1:3, the gas pressure is 1.0Pa, the sputtering power is 2000W, and the substrate temperature is normal...

Embodiment 2

[0033] Example 2: TiN / VO 2 .Mo / SiO 2 / Ag / Al 2 o 3 / Ag / Al 2 o 3 Film Preparation Method

[0034] The optical EVA film roll material with a thickness of 25um and a width of 1800mm is used as the substrate material A, and enters the reaction chamber of the magnetron sputtering device smoothly and continuously through a set of tension control guide rollers 3a, and the deposition surface of the substrate is placed downward, which can effectively To prevent granular impurities from contaminating the substrate surface, the reaction chamber is vacuumed to 2×10 -3 Pa, at Figure II In the 5ms-a target position, metal Ti is used as the target material, Ar is used as the sputtering gas and pure N2 is used as the reactive gas to supply the ion source into the reaction chamber, and the transparent Ti layer is deposited by DC reactive magnetron sputtering. Flow ratio of sputtering / reaction enhancing gas Ar:N 2 =1:2, the gas pressure is 1.0Pa, the sputtering power is 2800W, and the s...

Embodiment 3

[0045] Example 3: ZnO / Ag / ZnO / VO 2 .Cu / ZnO film preparation method

[0046] The substrate material A is a glass fiber cloth roll material with a thickness of 100um and a width of 2500mm, which enters the reaction chamber of the magnetron sputtering device smoothly and continuously through a set of tension control guide rollers 3a, and the deposition surface of the substrate is placed downward, which can effectively To prevent granular impurities from contaminating the substrate surface, the reaction chamber is vacuumed to 2×10 -3 Pa, at Figure II The medium 5ms-a target uses 99.99% alumina ceramics as the target material, Ar as the sputtering gas and pure O 2 As an auxiliary ion-enhanced gas input into the reaction chamber, a transparent ZnO layer is deposited by DC reactive magnetron sputtering. Sputtering / reaction enhancing gas flow ratio Ar:O 2 =1:3, the gas pressure is 1.0Pa, the sputtering power is 2000W, and the substrate temperature is 80°C, and the deposition growt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com