Laser color marking method for covers of books and printed matters

A printed matter and laser technology, which is applied in the field of laser color marking on the cover of books and printed matters, can solve the problem of fixed marking angle, etc., and achieve the effect of accurate marking, high energy input and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

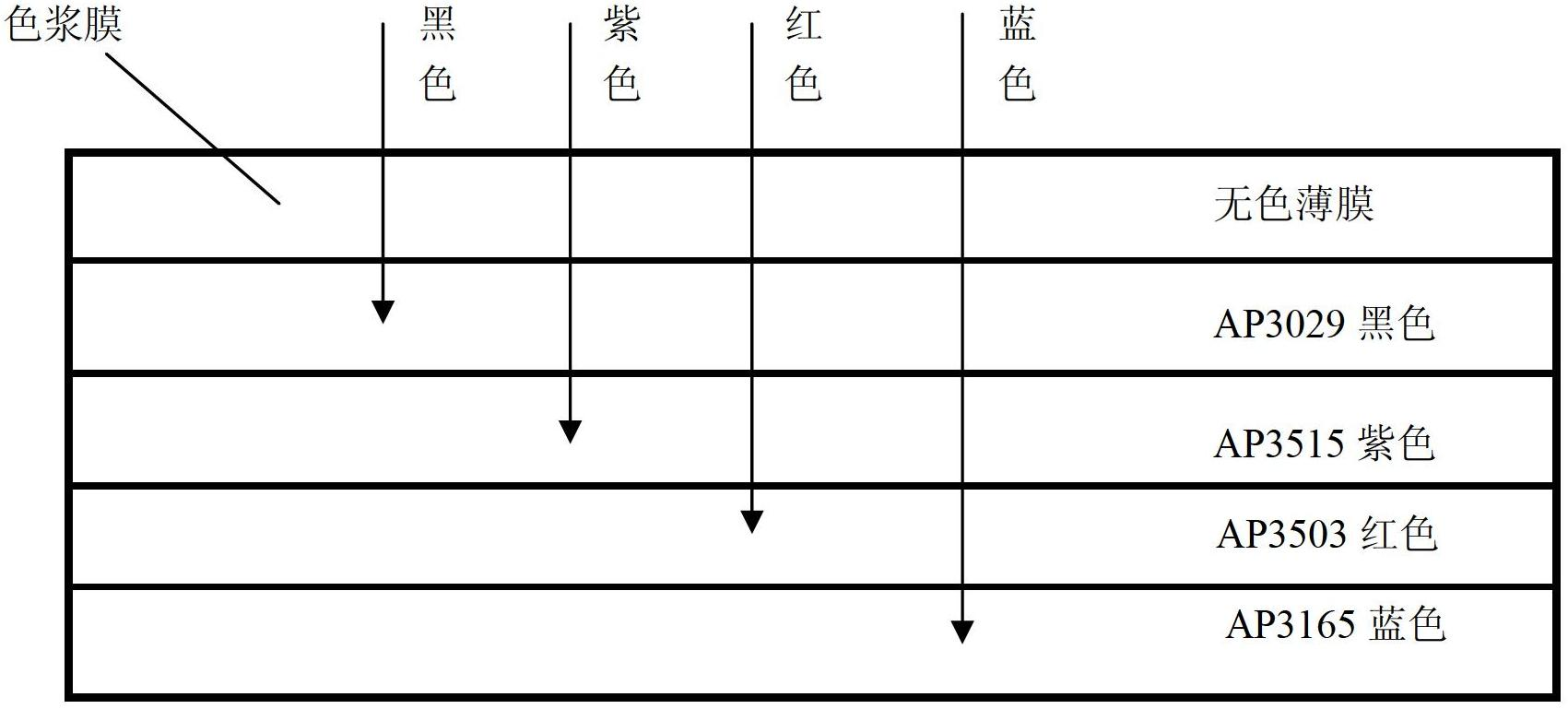

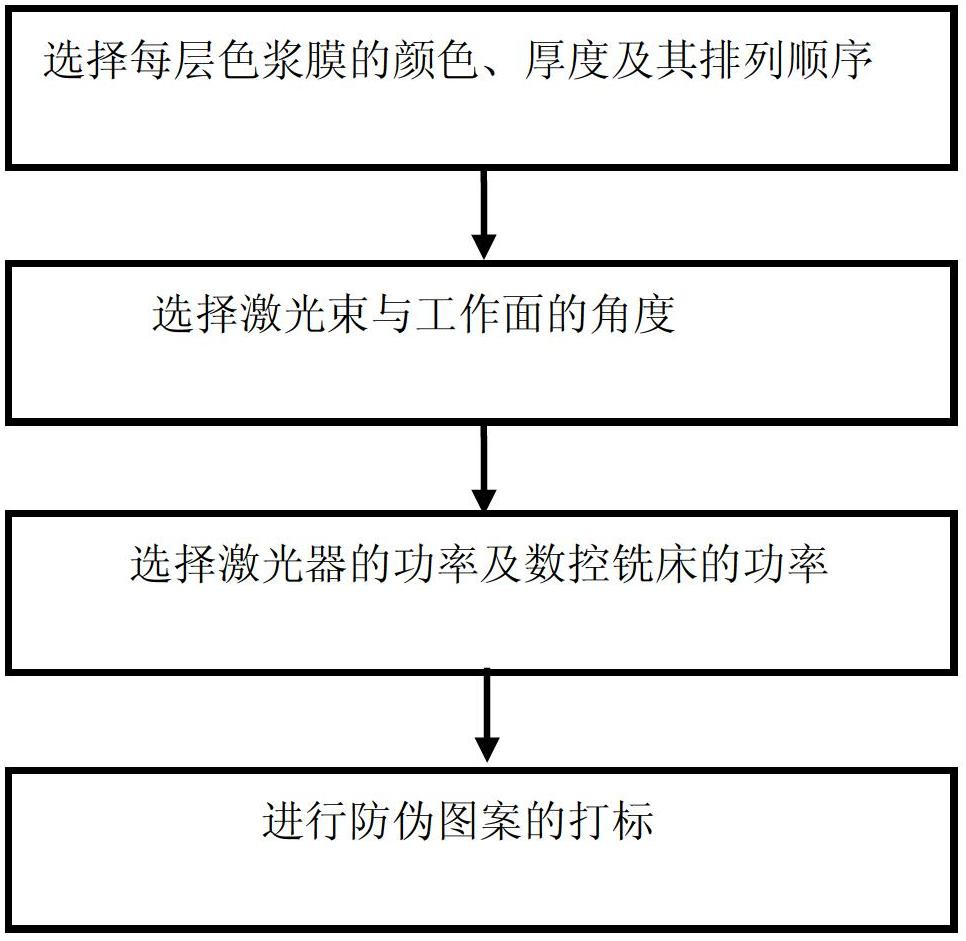

[0028] The anti-counterfeiting pattern of this embodiment is set as a two-dimensional code pattern, and its laser color marking method is carried out as follows: figure 1 as shown,

[0029] Step 1. According to the anti-counterfeiting pattern, the surface of the color paste film is a two-dimensional code pattern, and the thickness of each layer of the color paste film is set to 20 μm. The color band arrangement is colorless and black (AP3029) from the surface to the inside; the marking depth is 30± 5μm;

[0030] Step 2, using a CNC milling machine to select an angle of 90° between the laser beam and the working surface;

[0031] Step 3. Program the laser operation parameters into the CNC software and laser marking software, set the linear scanning speed to 200mm / s, set the frequency to 2KHz, and the pulse width to 40μs during marking;

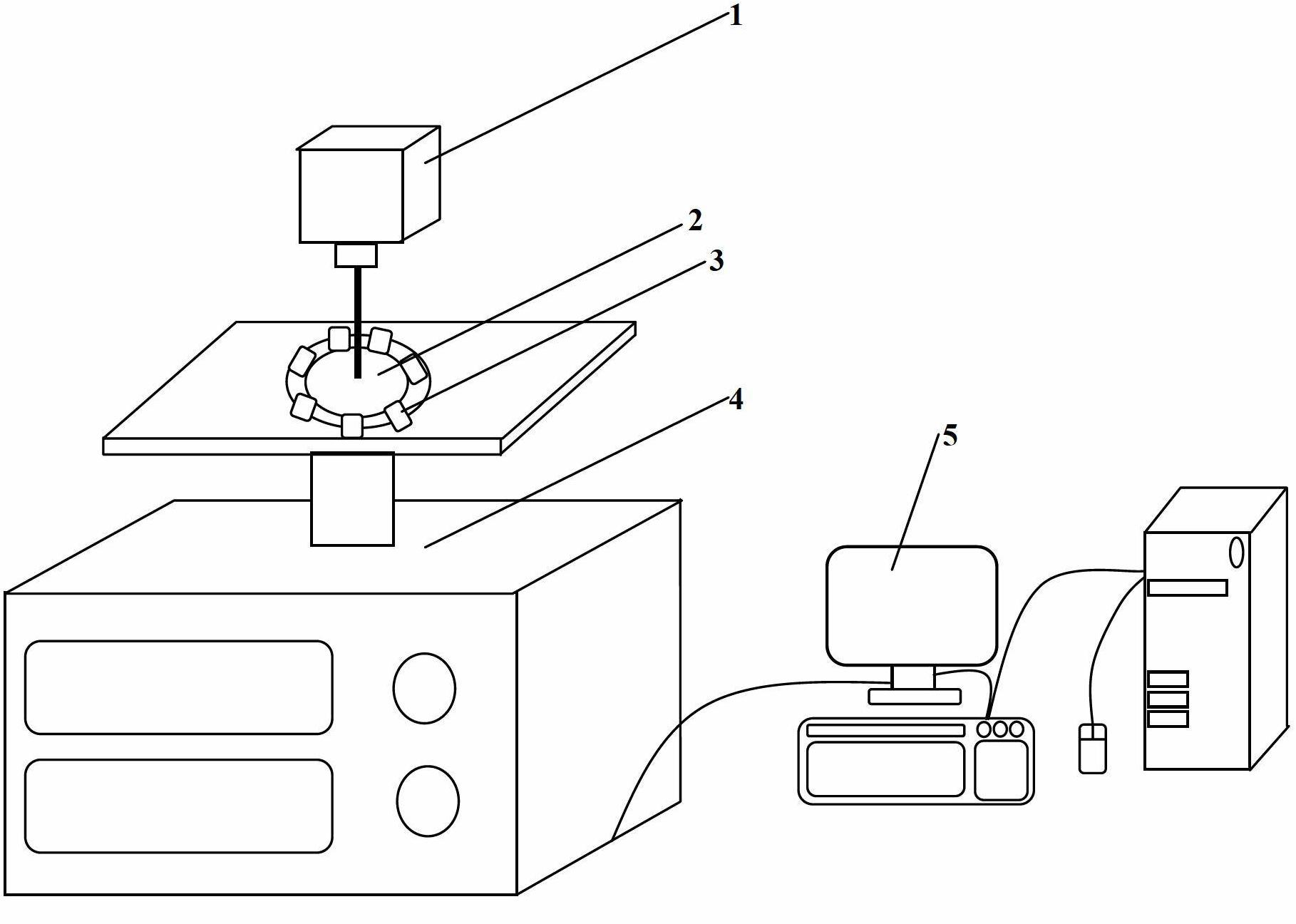

[0032] Step 4. Fix the scanned part on the worktable, and use the CNC milling machine's own CNC device control system and the laser marking ...

Embodiment 2

[0034] In this embodiment, the anti-counterfeiting pattern is set as Bauhinia, and its laser color marking method is carried out according to the following steps: figure 1 as shown,

[0035] Step 1. According to the color paste film of the anti-counterfeiting pattern Bauhinia, set the thickness of the color paste film to 30 μm per layer, and the arrangement of the color bands from the outside to the inside: colorless, black (AP3029), purple (AP3515), red (AP3503); The marking depth is: 75±5μm at the petal and 105±5μm at the stamen;

[0036] Step 2, using a CNC milling machine to select an angle of 80° between the laser beam and the working surface;

[0037] Step 3. Program the laser operation parameters into the CNC software and laser marking software, set the linear scanning speed to 150mm / s, set the frequency of the laser at the petal to 3kHz, and the pulse width to 80μs, set the frequency at the stamen to 4.5kHz, and the pulse width to 60μs ;

[0038] Step 4. Fix the sca...

Embodiment 3

[0040] The anti-counterfeiting pattern of this embodiment is set as the pattern of three Chinese characters "I love you", and its laser color marking method is carried out according to the following steps: figure 1 as shown,

[0041] Step 1. According to the anti-counterfeiting pattern "I love you", the color film thickness of the pattern of the three Chinese characters is 40 μm per layer, and the color bands are arranged from the surface to the inside as colorless, black (AP3029), purple (AP3515), red (AP3503) . The marking depth is 60±10μm for “I”, 100±10μm for “Love”, and 140±10μm for “You”;

[0042] Step 2, using a CNC milling machine to select an angle of 75° between the laser beam and the working surface;

[0043] Step 3. Program the laser operation parameters into the CNC software and laser marking software to set the linear scanning speed to 100mm / s, set the frequency of the laser to 6KHz with the word "I", and set the pulse width to 70μs, and set the frequency of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com