Water Reduction Method for Sintering Mixture

A technology of sintering mixture and moisture content, which is applied in the field of sintering technology in the metallurgical industry to achieve the effects of reducing costs, reducing process energy consumption, and reducing wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

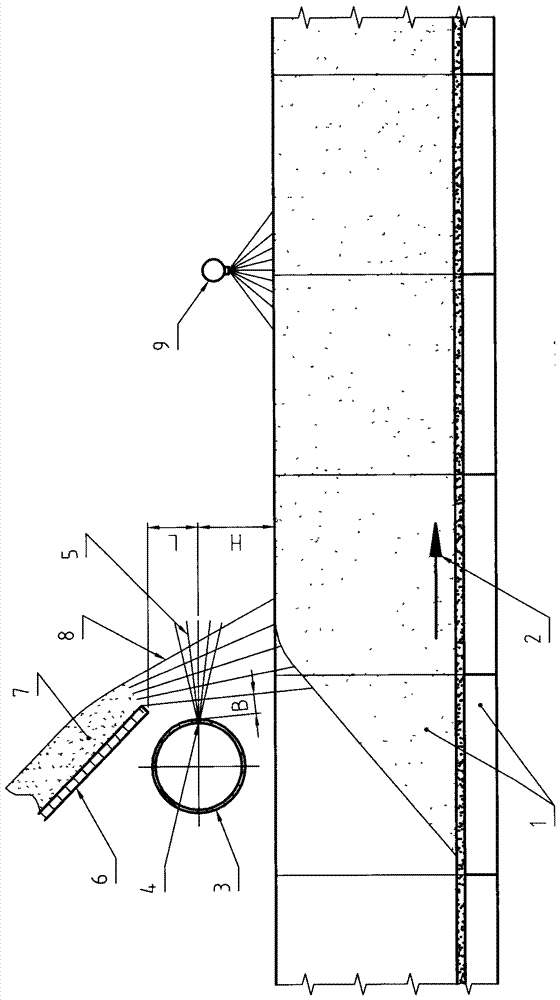

[0023] Example 1, such as figure 1 shown.

[0024] exist figure 1 Among them, 1 represents the sintering trolley and its sintering mixture. 2 is an arrow representing the moving direction of the sintering trolley. The 3rd is the blowing main pipe, which is a round pipe shown in the figure, and it can also be a rectangular pipe or other special-shaped pipes. 4 is the spout made on the blowing main pipe 3, specifically to the present embodiment, this spout is a long slit with a width of 2.5-3 millimeters, but it does not rule out that it adopts other forms. 5 is the flow line which shows the airflow ejected from the nozzle 4. 6 is a blanking slide plate representing the sintered mixture. 7 represents the sintered mixture in the falling process. 8 represents the streamline of the sintered mixture 7 in the falling process. 9 is a water mist injection pipe, which adds an appropriate amount of moisture to the surface of the sintered mixture through the water mist nozzle. ...

Embodiment 2

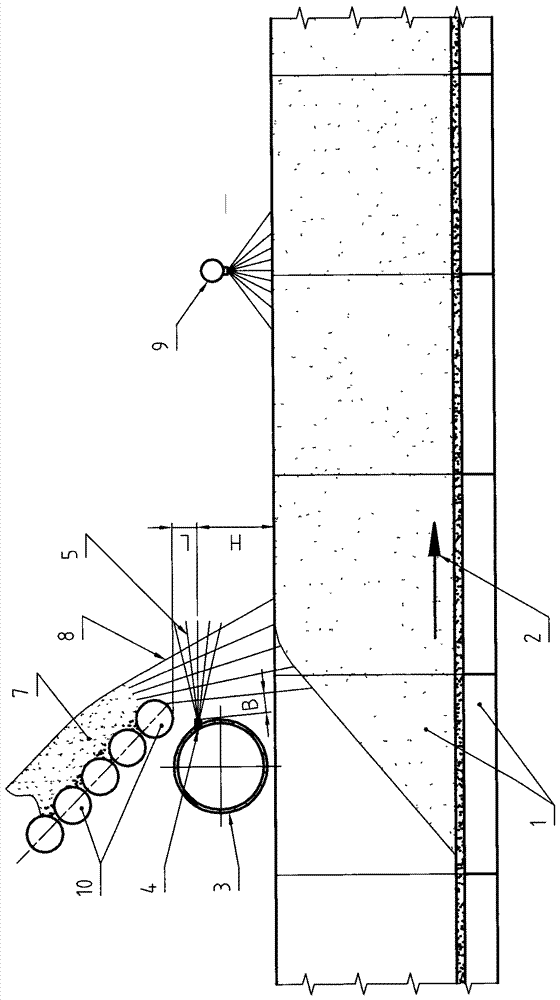

[0027] Example 2, such as figure 2 shown.

[0028] The present embodiment has carried out a little change on the basis of embodiment 1: replace the drop slide plate 6 in embodiment 1 with multi-roll distributor 10; At this time, the distance L between the spout 4 and the lower edge of the multi-roll distributor 10, which is the feeding mechanism for the sintered mixture, can be determined according to 120 mm.

[0029] For the rest, refer to the relevant description of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com