Lead-free copper alloy wire material and preparation method thereof

A lead-copper alloy and alloy wire technology, applied in the field of preparation of environment-friendly copper alloy materials, can solve problems such as difficulty in guaranteeing quality stability, inability to satisfy connectors, and easy cracks in wire blanks, and achieve low cost and production process. Short, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

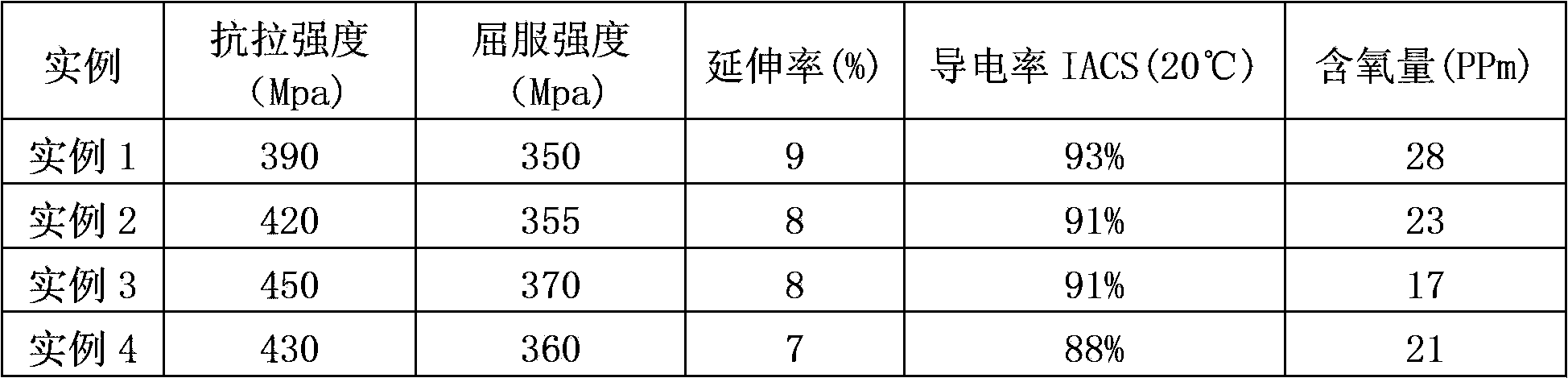

Examples

example 1

[0018] Take 0.2 parts of tellurium, 0.02 parts of trace elements, and 99.78 parts of copper; wherein, the trace elements are composed of the following components and parts by weight: 0.009 parts of phosphorus, 0.001 parts of boron, and 0.01 parts of magnesium;

[0019] The process of horizontal continuous casting wire billet is to put the above components into the furnace body respectively. The furnace body is a cored induction melting furnace and a cored induction holding furnace installed through a submerged launder. The melting sequence in the cored induction melting furnace is First add 99.78 parts of copper, then add 0.01 parts of trace elements, and finally add 0.2 parts of tellurium. The temperature in the cored induction melting furnace is 1150°C-1250°C. When the chemical components in the cored induction melting furnace melt After the copper alloy liquid is formed, the copper alloy liquid in the cored induction melting furnace flows into the cored induction holding fur...

example 2

[0023] Take 0.4 parts of tellurium, 0.03 parts of trace elements, and 99.57 parts of copper; wherein, the trace elements are composed of the following components and parts by weight: 0.008 parts of phosphorus, 0.002 parts of boron, and 0.02 parts of magnesium;

[0024] The process of horizontal continuous casting wire billet is to put the above components into the furnace body respectively. The furnace body is a cored induction melting furnace and a cored induction holding furnace installed through a submerged launder. The melting sequence in the cored induction melting furnace is First add 99.57 parts of copper, then add 0.015 parts of trace elements, and finally add 0.4 parts of tellurium. The temperature in the cored induction melting furnace is 1150°C-1250°C. When the chemical components in the cored induction melting furnace melt After the copper alloy liquid is formed, the copper alloy liquid in the cored induction melting furnace flows into the cored induction holding fu...

example 3

[0027] Take 0.6 parts of tellurium, 0.05 parts of trace elements, and 99.35 parts of copper; wherein, the trace elements are composed of the following components and parts by weight: 0.01 parts of phosphorus, 0.012 parts of boron, and 0.028 parts of magnesium;

[0028]The process of horizontal continuous casting wire billet is to put the above components into the furnace body respectively. The furnace body is a cored induction melting furnace and a cored induction holding furnace installed through a submerged launder. The melting sequence in the cored induction melting furnace is First add 99.35 parts of copper, then add 0.03 parts of trace elements, and finally add 0.6 parts of tellurium. The temperature in the cored induction melting furnace is 1150°C-1250°C. When the chemical components in the cored induction melting furnace melt After the copper alloy liquid is formed, the copper alloy liquid in the cored induction melting furnace flows into the cored induction holding furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com