Production process of raw material for coated white board paper

A production process and technology of whiteboard paper, applied in the directions of fiber raw material, raw material separation, fiber raw material processing, etc., can solve the problems affecting the thickness of coated whiteboard paper, the quality of waste paper fiber, and the shortage of waste paper raw materials, etc. Collection and application, low equipment cost, improved paper thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

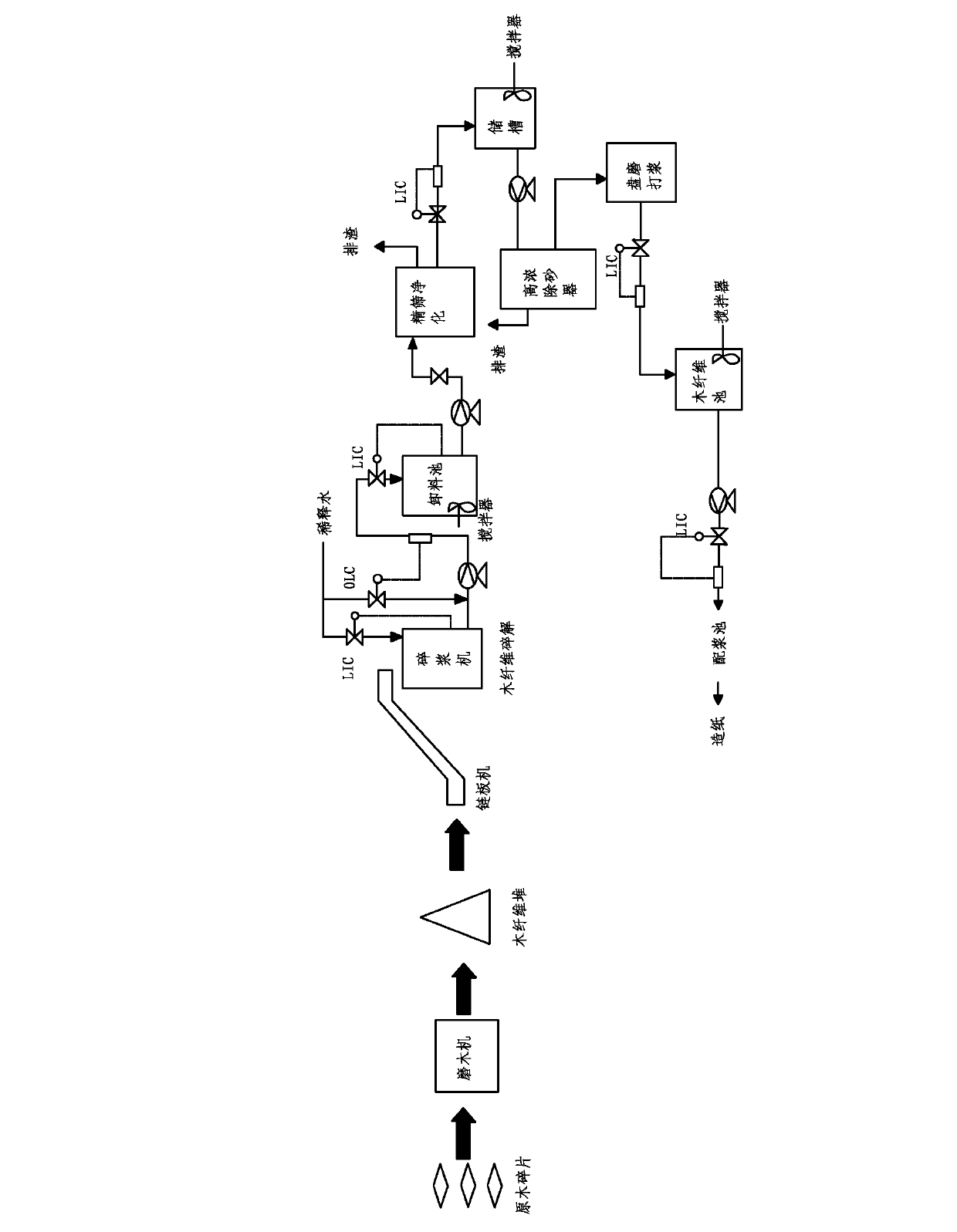

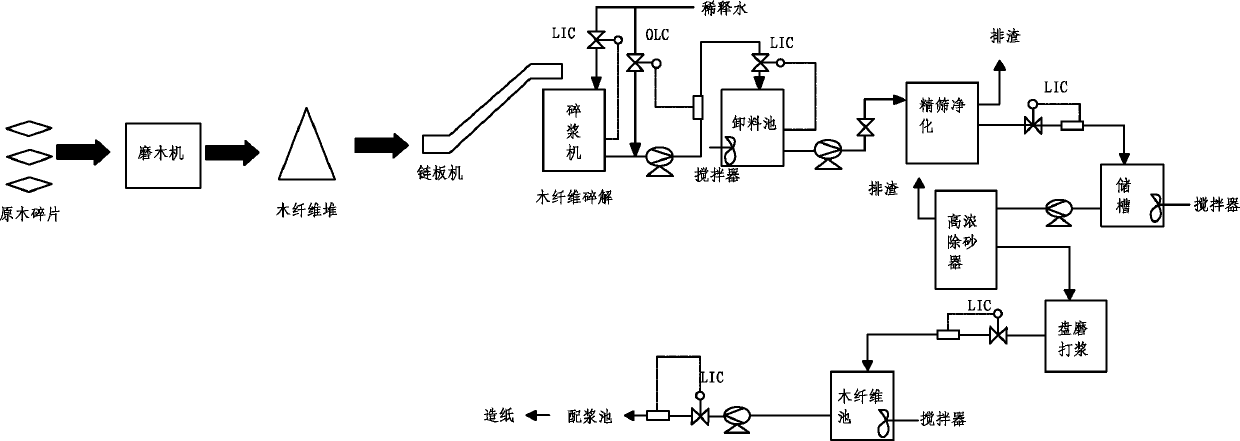

[0037] like figure 1 As shown, the production process of a kind of raw material for coating white board paper in the present embodiment comprises the following process steps: Log milling: the log chips are ground into wood fibers by a wood grinder: the length of the log chips is 5cm, and the width is 2cm , the thickness is 0.5cm; the wood fiber length is 0.8cm, and the width is 0.7mm; wood fiber disintegration: the wood fiber is transported to the pulper through the chain plate machine, dispersed and disintegrated by adding water, and prepared into 6% mass percent concentration Uniformly dispersed wood fiber slurry, the wood fiber in the wood fiber slurry is 0.8cm long and 0.2mm wide; purification treatment: use a fine sieve to separate and purify impurities with a particle size of ≧0.25mm in the wood fiber slurry Wood fiber pulp. The sieve aperture of fine sieve is 0.25mm, and the pressure of fine sieve is 250KPa; desanding treatment: use high-concentration desander to remov...

Embodiment 2

[0040] like figure 1As shown, the production process of a raw material for coating whiteboard paper in this embodiment includes the following process steps: Log milling: the log chips are ground into wood fibers by a wood grinder: the length of the log chips is 3cm, and the width is 1cm , the thickness is 0.2cm; the wood fiber length is 0.5cm, and the width is 0.4mm; wood fiber disintegration: the wood fiber is transported to the pulper through the chain plate machine, dispersed and disintegrated by adding water, and prepared into 4% mass percentage concentration Uniformly dispersed wood fiber slurry, the wood fiber in the wood fiber slurry is 0.5cm in length and 0.12mm in width; purification treatment: use a fine sieve to separate and purify impurities with a particle size of ≧0.18mm in the wood fiber slurry Wood fiber pulp. The sieve aperture of fine sieve is 0.18mm, and the pressure of fine sieve is 210KPa; desanding treatment: use high-concentration desander to remove imp...

Embodiment 3

[0043] like figure 1 As shown, the production process of a kind of raw material for coating whiteboard paper in the present embodiment comprises the following process steps: Log milling: the log chips are ground into wood fibers by a wood grinder: the length of the log chips is 2 cm, and the width is 0.5 cm. cm, thickness is 0.1cm; wood fiber length is 0.2cm, width is 0.2mm; wood fiber disintegration: wood fiber is transported to pulper through chain plate machine, add water to disperse, disintegrate, and prepare into 3% mass percent concentration Evenly dispersed wood fiber slurry, the wood fiber in the wood fiber slurry is 0.2cm in length and 0.05mm in width; purification treatment: use a fine sieve to separate impurities with a particle size ≥ 0.1mm in the wood fiber slurry, and purify Wood fiber pulp. The sieve aperture of fine sieve is 0.1mm, and the pressure of fine sieve is 180KPa; desanding treatment: use high-concentration desander to remove impurities with high dens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com