Variable cross section construction method for underground continuous wall

An underground diaphragm wall and construction method technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve problems such as hidden dangers of engineering quality, placement in grooves, wall inclination, etc., to achieve stable construction quality, convenient construction, The effect of structural stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with specific examples.

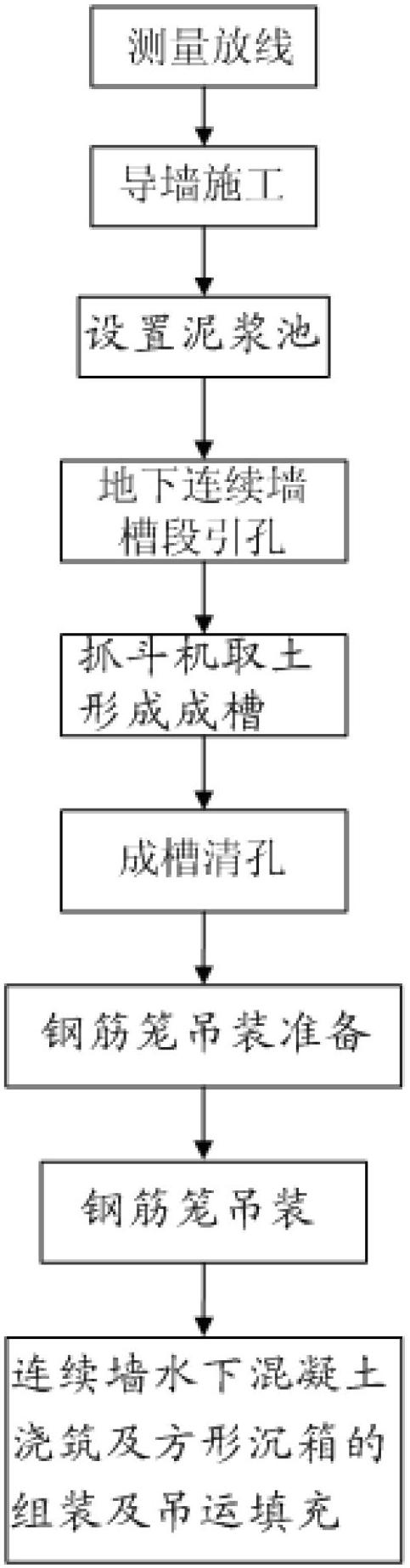

[0047] see figure 1 , a kind of variable section construction method of underground diaphragm wall of the present invention, comprises the following steps:

[0048] First, measure and set out the line, use the known coordinate control points around the site, use the total station to determine the control point of the axis of the underground diaphragm wall, and lead out the axis;

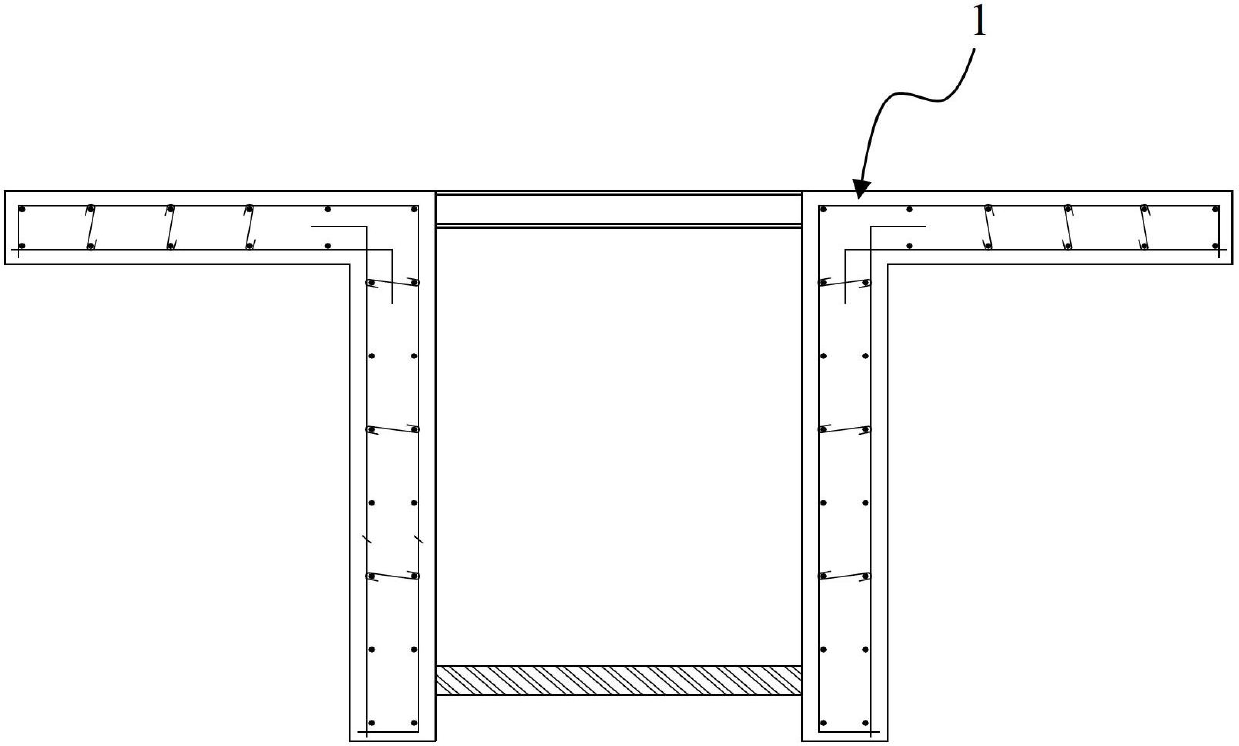

[0049] Then, the guide wall 1 is constructed, and the guide wall 1 is poured on the periphery of the underground continuous wall; the top of the guide wall 1 extends outward;

[0050] See figure 2 , the guide wall 1 plays the role of supporting the notch soil, according to the geological conditions of the construction area, the guide wall 1 is made Shaped cast-in-place reinforced concrete structure, the inner clear width is 50mm wider than the continuous wall. Each corner of the guide wall 1 ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com