Travelling-wave valveless piezoelectric micropump of multistage diffusion micro-flow pipeline

A diffusion tube and pipeline technology, which is applied in the field of valveless piezoelectric micropumps, can solve the problems of low efficiency, inadaptability to the technical requirements of microfluidic chips, and poor reverse flow stop performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

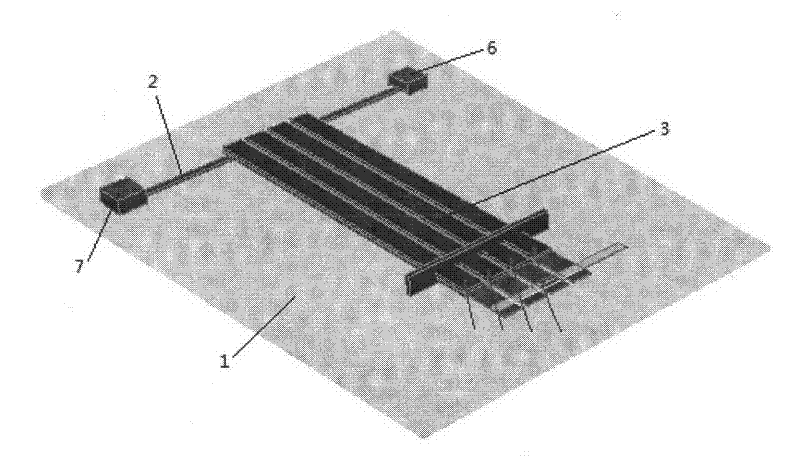

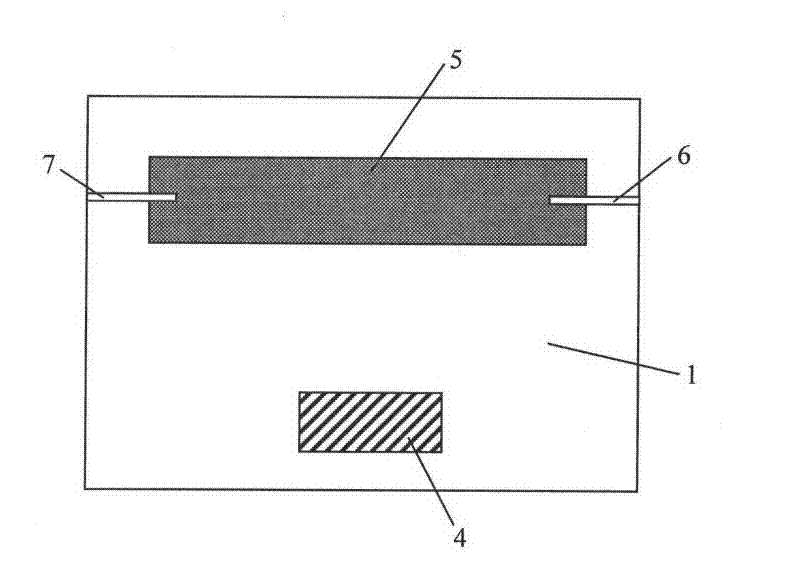

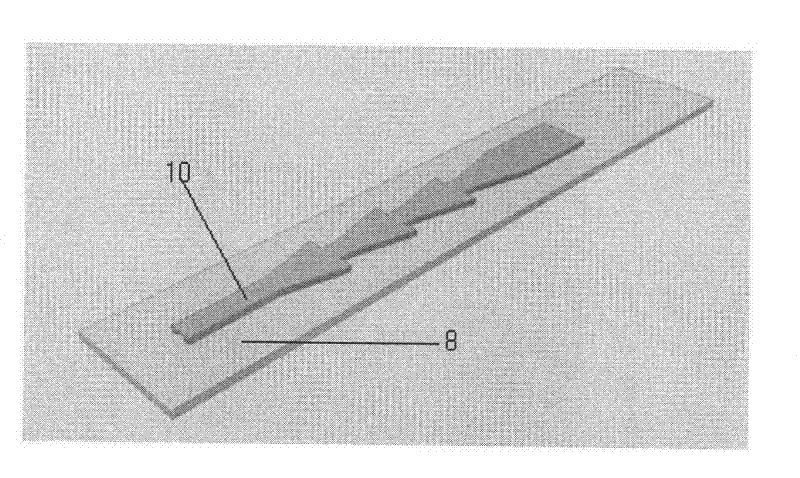

[0040] The manufacturing process of the micropump is closely related to the selection of materials, and different materials adopt different micromachining methods. Micropump substrate and microfluidic channel mold materials can be made of silicon or PMMA (polymethyl methacrylate), silicon material can use plasma etching process, compatible with mature MEMS process; and PMMA has good optical properties, chemical stability Sexual and mechanical properties, are widely used as structural materials for micropumps, and micromachining methods can be used.

[0041]The micro-pump substrate and micro-fluid pipeline mold made of PMMA material were fabricated by micromachining method, and a 100 μm-deep micro-fluid pipeline bonding area and a certain depth of piezoelectric drive array slots were fabricated on the surface of the micro-pump substrate; while the micro-fluid pipeline mold The internal height of the pipe is 100 μm, and the wall thickness of the pipe is 300 μm; the two opening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com