Ultra-compact high-pressure ratio oblique flow-centrifuge combined compressor structure

A centrifugal compressor and compressor technology, applied in the field of compressors, can solve the problems of increasing the windward area and weight of the engine, the large radial size of the two-stage centrifugal compressor, and increasing the difficulty of bearing design, so as to shorten the support span, Reduce the difficulty of design and reduce the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

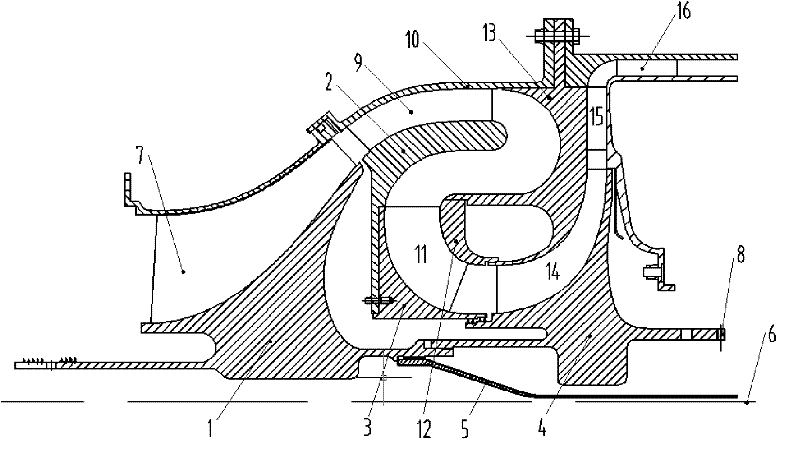

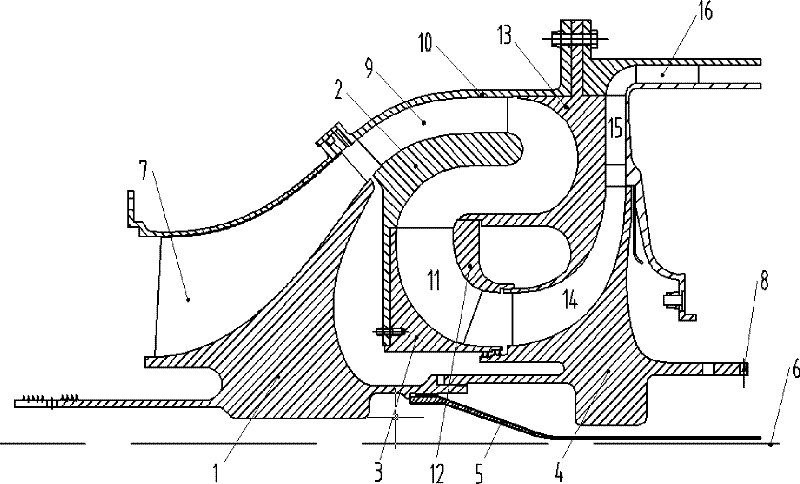

[0025] see figure 1 , the ultra-compact high-pressure ratio oblique flow-centrifugal combined compressor structure of the present invention consists of oblique flow impellers, small-diameter "S" elbows with rectifiers and return blades, centrifugal impellers, radial diffusers and axial diffusers The device is composed of six parts, wherein the oblique flow impeller is composed of the oblique flow impeller disc 1 and the oblique flow rotor blade 7, the centrifugal impeller is composed of the centrifugal impeller disc 4 and the centrifugal rotor blade 14, and the oblique flow impeller and the centrifugal impeller are connected by a section of radial Ultra-compact "S" elbow connection with small size, the inner wall of the "S" elbow is composed of inner wall part 2 and inner wall part 3, the outer wall of the elbow is composed of outer wall part 10, outer wall part 12 and outer wall part 13, the inlet of the elbow A row of rectifier vanes 9 is arranged and a row of recirculator v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com