LED (light-emitting diode) optical module for lighting, and LED chip

A technology of LED chips and optical modules, applied in lighting and heating equipment, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

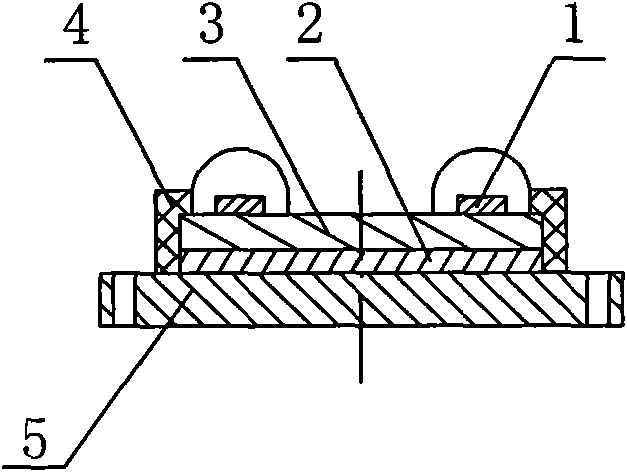

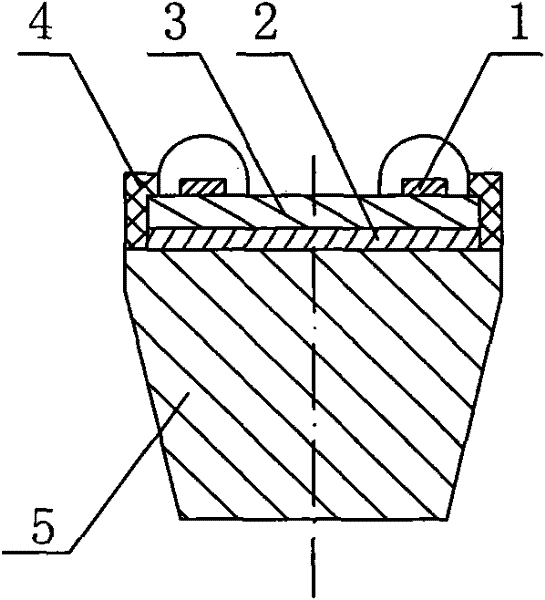

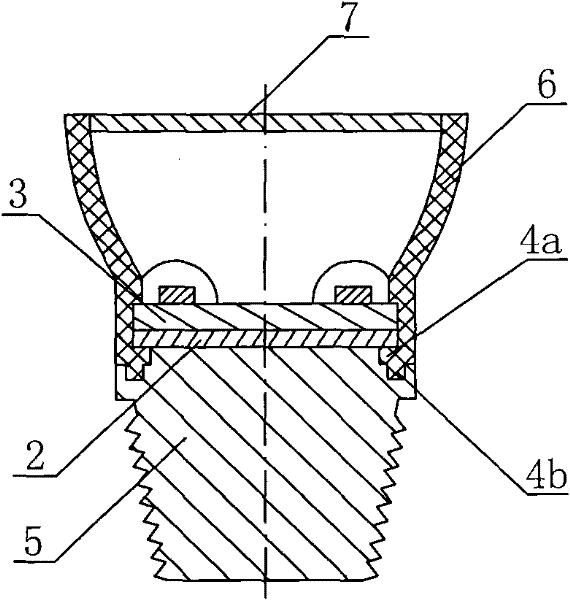

[0030] figure 1 In the shown LED light module of the present invention, the heat conduction core 5 is a flat plate structure, and is provided with mounting and fixing holes, and two LED chips 1 are shown in the figure. When there are multiple LED chips, attention should be paid to the design. The distribution of LED chips on the thermal diffusion plate should be radially dispersed. The power of a single LED chip should not be too large, preferably not more than 2 watts. The outer layer insulator 4 surrounds the edge sidewall of the thermal diffusion plate 3, and the outer layer insulator 4 extends to the high-voltage insulating sheet 2, and together with the high-voltage insulating sheet, the thermal diffusion plate is insulated from the heat-conducting core (and nearby conductors), thereby playing a role For high-voltage insulation, the insulation strength of the outer insulator should be higher than that of the high-voltage insulation sheet.

[0031] figure 2 The LED ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com