Fault diagnosis and fault tolerance control method and system used for material tracking system

A fault diagnosis and tracking system technology, applied in the direction of lighting and heating equipment, furnace types, furnaces, etc., can solve the problems of grating equipment material tracking information confusion, no automatic compensation recovery mechanism, manual adjustment, etc., to achieve enhanced fault diagnosis and fault tolerance, prolonging high-efficiency production time, and reducing maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

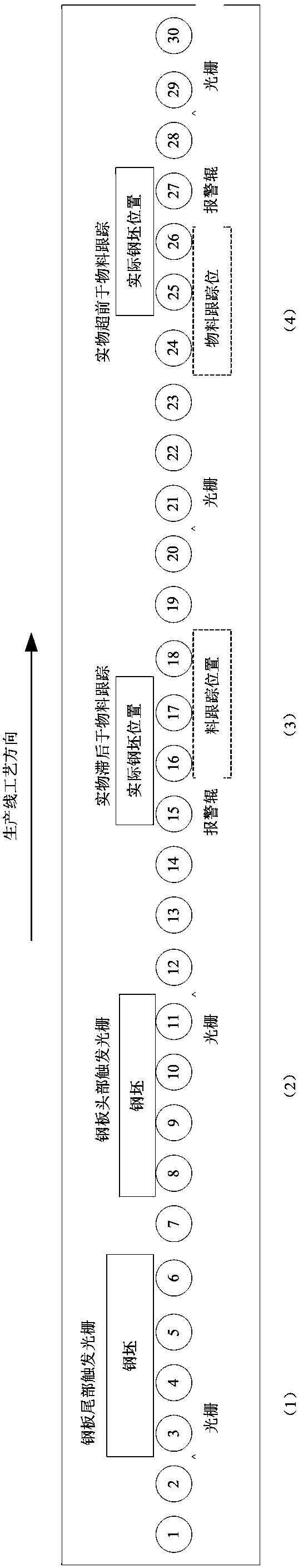

[0034] Such as figure 1 Furnace material tracking structure shown.

[0035] The heat treatment furnace is equipped with 4 gratings along the process direction of the production line, and there are 30 roller tables in total. Each roller table is driven by a frequency converter. With the 1# roller table as the origin, and the distance between the rollers is 600mm, all the gratings and roller tables can be obtained. The specific position of the 1# roller table.

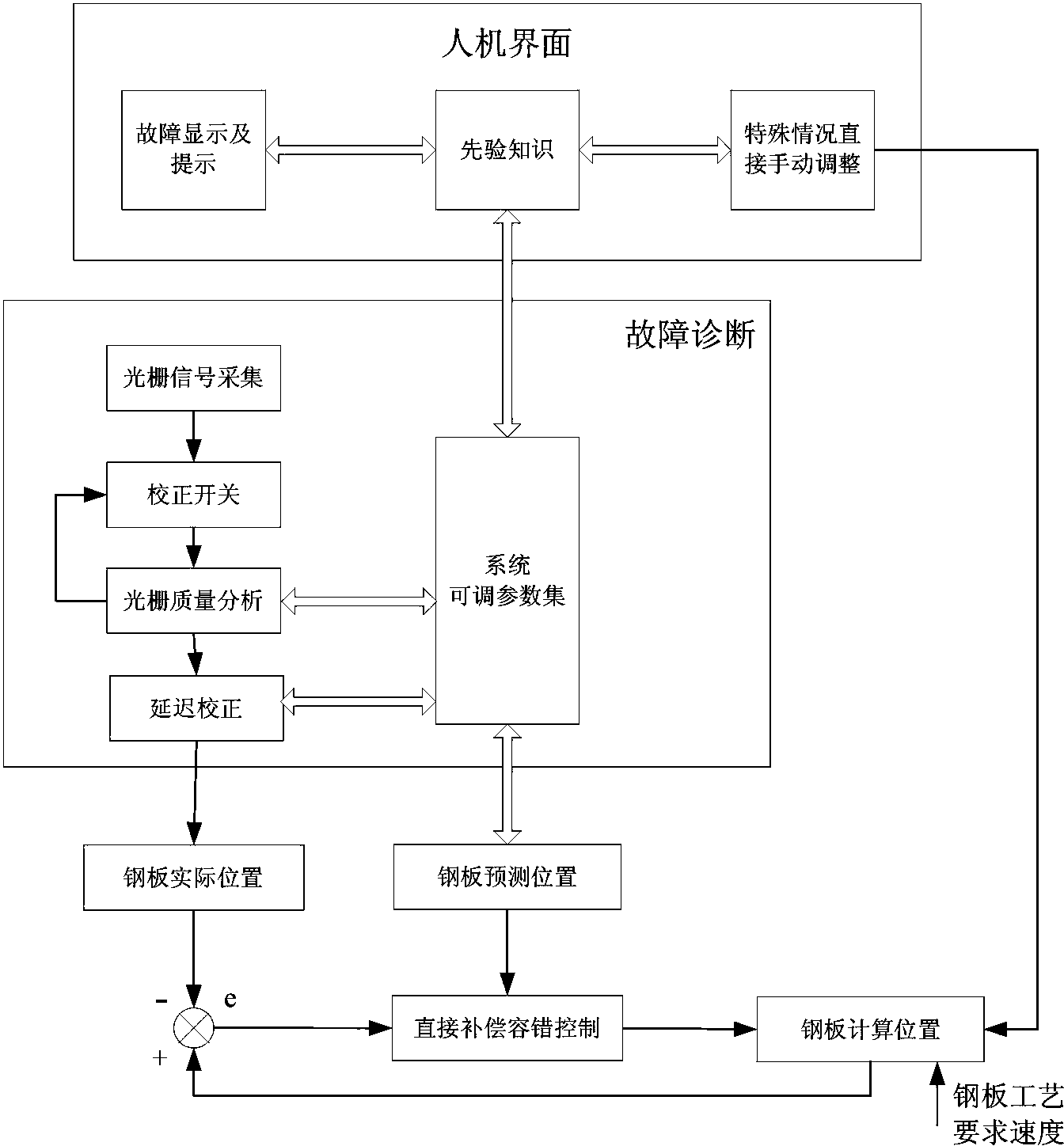

[0036] This embodiment provides a fault diagnosis and fault-tolerant control method for a material tracking system, the steps of which are:

[0037] 1. First set the required parameters;

[0038] The parameters that need to be set include: grating sampling period, grating health weight , raster health weight , Flashing error signal threshold 最大值 , Flashing error signal threshold 最小值 , long time false signal threshold 最大值 , long time false signal threshold 最小值 , Raster health warning line, minimum delay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com