Automatic-stirring smelting furnace

An automatic stirring and smelting furnace technology, applied in the direction of stirring devices, furnaces, furnace components, etc., can solve the problems of uneven stirring, high labor intensity, secondary pollution, etc., to avoid overheating and overburning, reduce labor intensity, and save energy. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

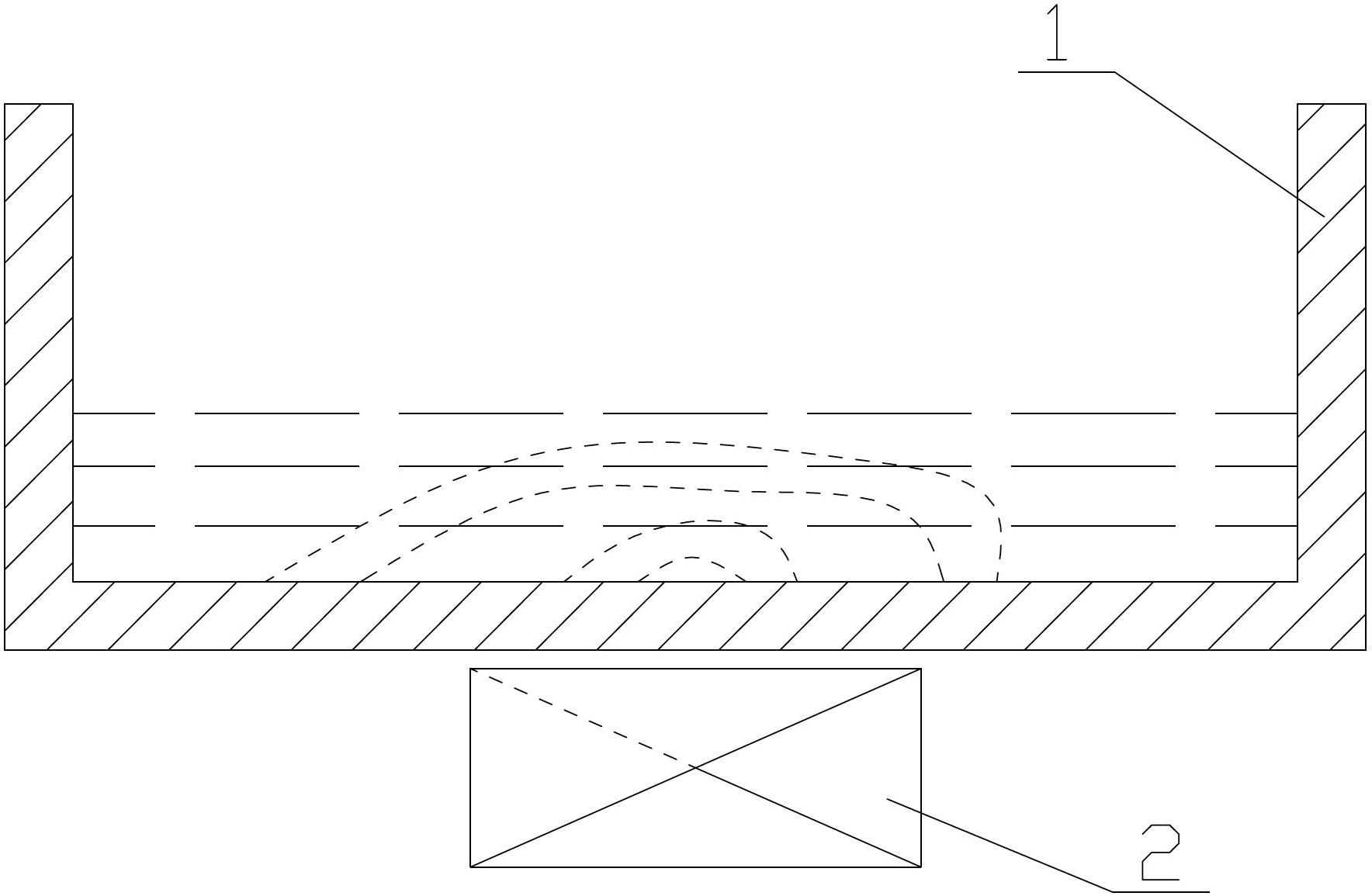

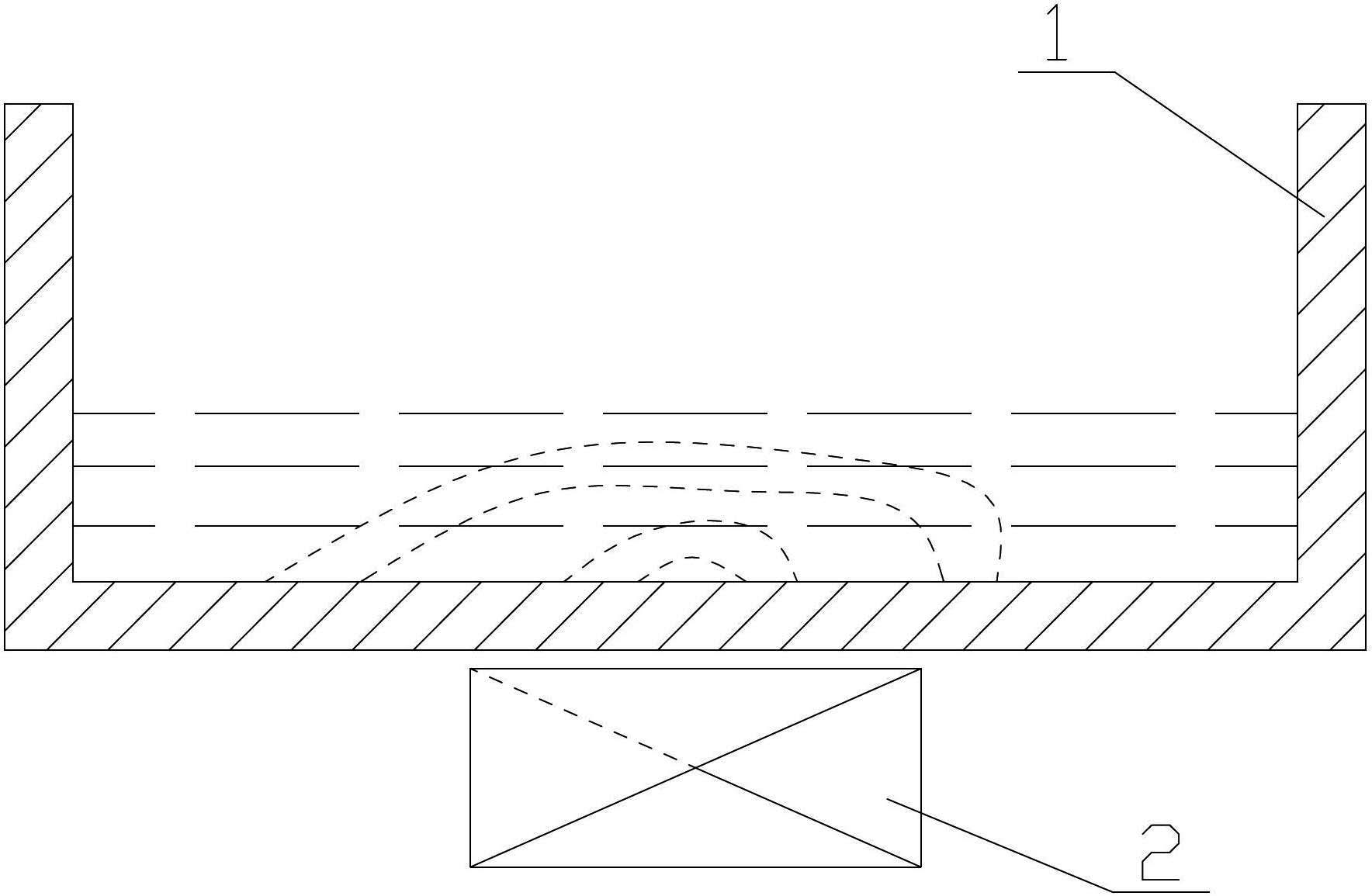

[0025] Please refer to figure 1 as shown, figure 1 It is a structural schematic diagram of the automatic stirring melting furnace of the present invention; in this embodiment, an automatic stirring melting furnace includes a furnace body 1, the furnace body 1 is provided with a feed inlet and a discharge outlet, and the bottom of the furnace is A permanent magnetic stirrer 2 is provided, and the permanent magnetic stirrer 2 includes a permanent magnet inductor, and the permanent magnet inductor is sleeved on the rotating shaft of the variable frequency motor, which is 6 permanent magnets distributed at intervals in the circumferential direction, The permanent magnets are NdFeB permanent magnets, and the polarities of adjacent permanent magnets are opposite.

[0026] When working, the magnetic fiel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com