A spectroscopic measuring device

A spectrum measurement and spectrum technology, which is applied in the field of optical radiation measurement, can solve the problems of large measurement error, stray light and mixing in the measurement device, and achieve the effect of reducing the level of stray light and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

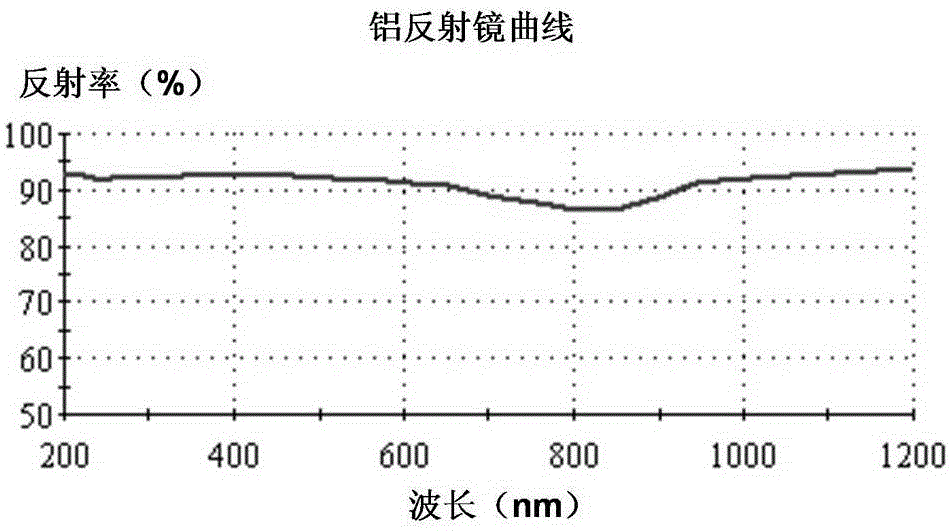

[0031] Such as Figure 4 As shown, this embodiment discloses a polychromator, including an incident slit 1, a dispersion element 2, an imaging element 3, a spectrally selective film 4 and an array detector. In this embodiment, the dispersion element 2 is a plane grating, the imaging element 3 is a concave mirror, and the spectrally selective thin film 4 coated on the concave mirror 3 is a reflective film.

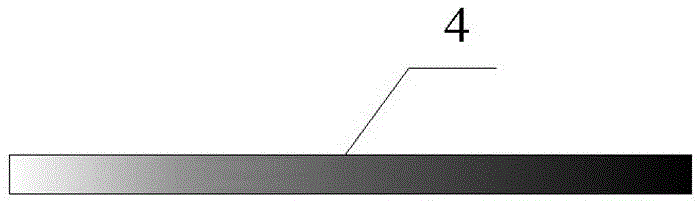

[0032] Such as figure 2 As shown, the spectrally selective reflective film 4 of this embodiment is composed of four reflective films with different selective bands, and the corresponding reflective bands are respectively 350nm-500nm, 450nm-600nm, 480nm-700nm and 500nm-800nm. The reflection bands of the reflective film overlap at the first place, and cover the measurement band of 380nm-780nm of the spectrum measuring device.

[0033] After the incident light is split by the plane grating 2, the monochromatic light of different bands is incident on the concave mirror 3. Si...

Embodiment 2

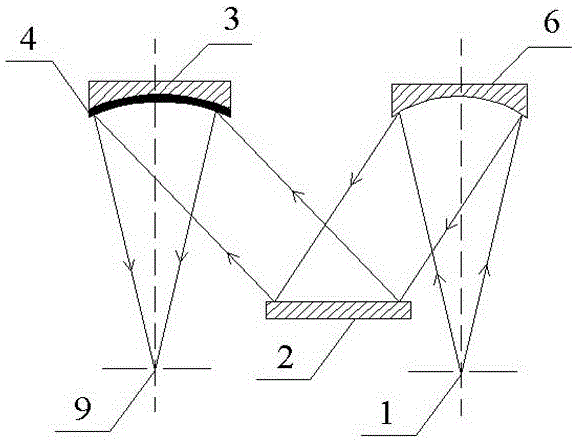

[0036] Such as Figure 5 As shown, this embodiment discloses a monochromator, including an incident slit 1 , a dispersion element 2 , an imaging element 3 , a spectrally selective film 4 , a collimating mirror 6 , an exit slit 9 and a motor 10 . In this embodiment, the dispersion element 2 is a plane grating, the imaging element 3 is a concave reflector, and the spectrally selective film 4 coated on the concave reflector 3 is a reflective film.

[0037] In the actual measurement, the light enters through the incident slit 1, and after being reflected by the collimator 6, it becomes a beam of parallel light incident on the plane grating 2. The plane grating 2 disperses the incident light and projects it on the concave mirror 3, and the concave surface reflects The spectrally selective reflection film 4 on the mirror 3 reflects the corresponding light according to its reflection band, and exits through the exit slit 9 .

[0038] Such as Figure 6 As shown, this embodiment also...

Embodiment 3

[0040] Such as Figure 7 As shown, this embodiment discloses a double monochromator, including an incident slit 1, two dispersive elements 2, two imaging elements 3, a spectrally selective film 4, four mirrors 7, and two collimating mirrors 6, and exit slit 9. The two dispersion elements 2 in the present embodiment are all planar gratings, and the two imaging elements 3 are all concave reflectors with the same structure and size, and the spectrally selective thin films 4 plated on the concave reflector 3 are reflective films. The spectrum selective reflection film 4 on the concave reflector 3 in the example is as figure 2 As shown, the selected wavelength band is the same as that in Embodiment 1, and the corresponding positions of the reflective film on the two concave reflectors 3 are exactly the same.

[0041] During measurement, the light enters through the incident slit 1, and after being reflected by the reflector 7, it is reflected by the collimator 6 as a beam of par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com