Novel eddy-current sensor probe

An eddy current sensor, a new type of technology, applied in the field of eddy current detectors, can solve the problems of high-quality sensor probes that have not been seen yet, and achieve the effects of strong defect resolution, stable work, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will be further described in conjunction with the accompanying drawings, not to limit the scope of the present invention.

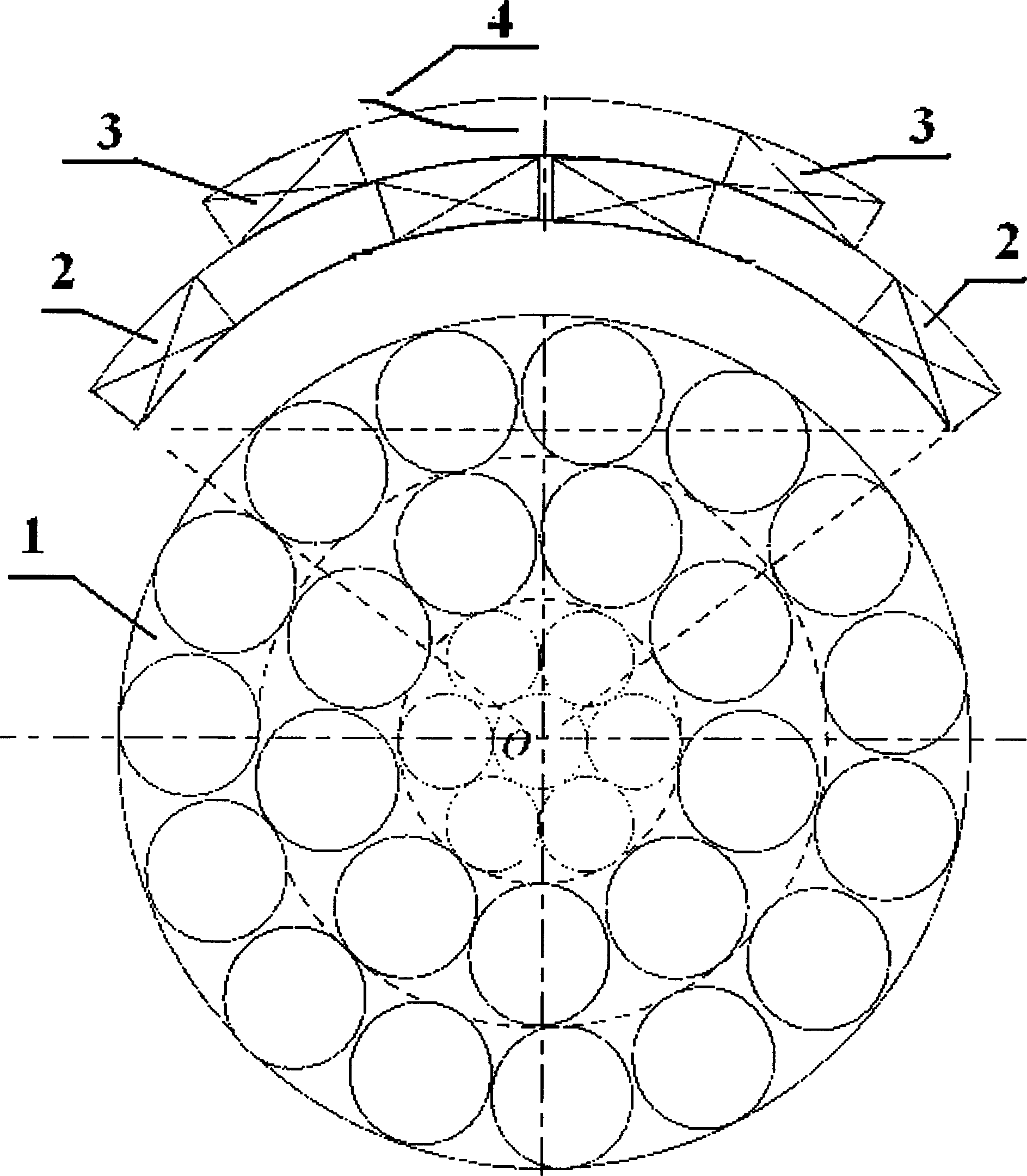

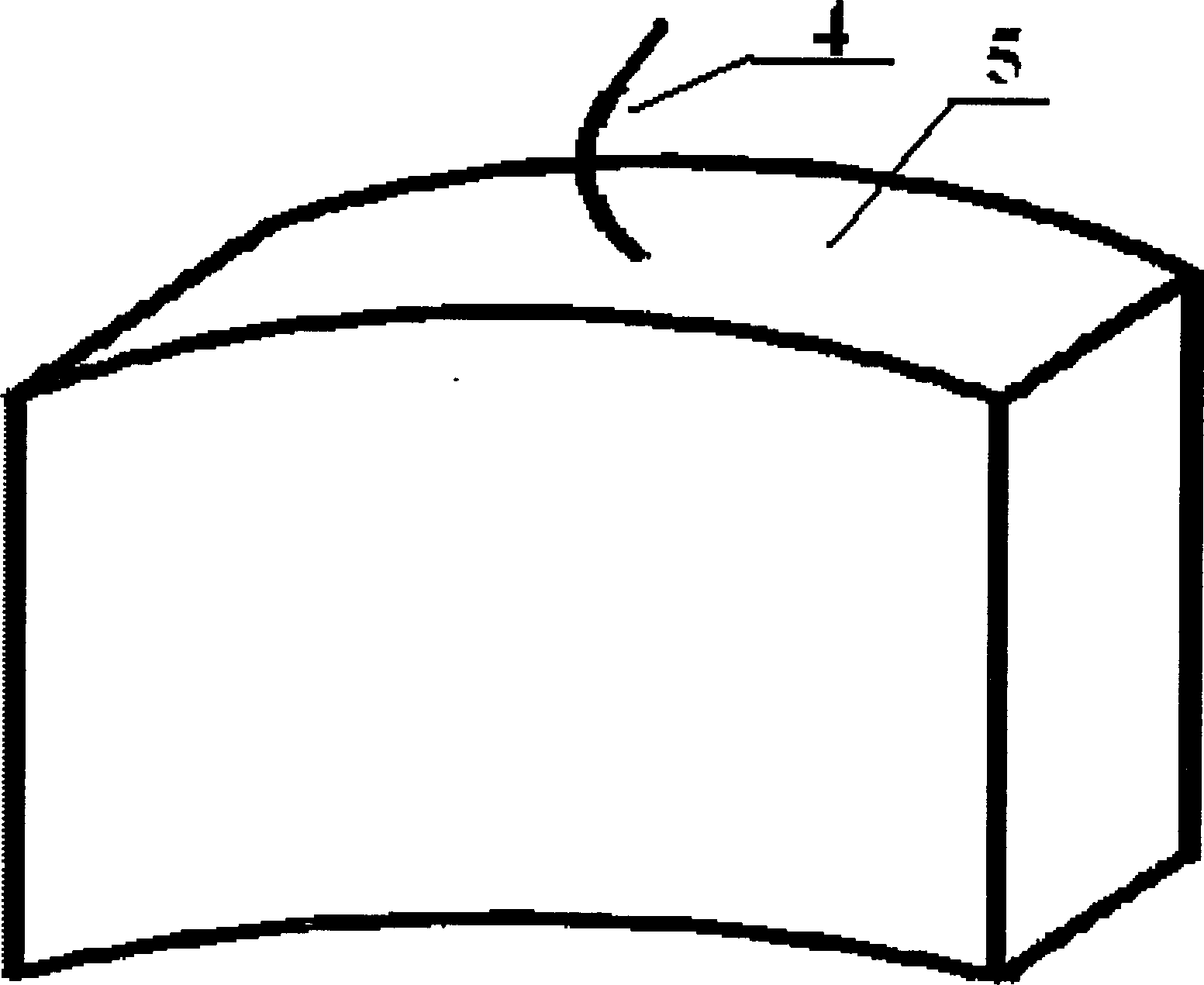

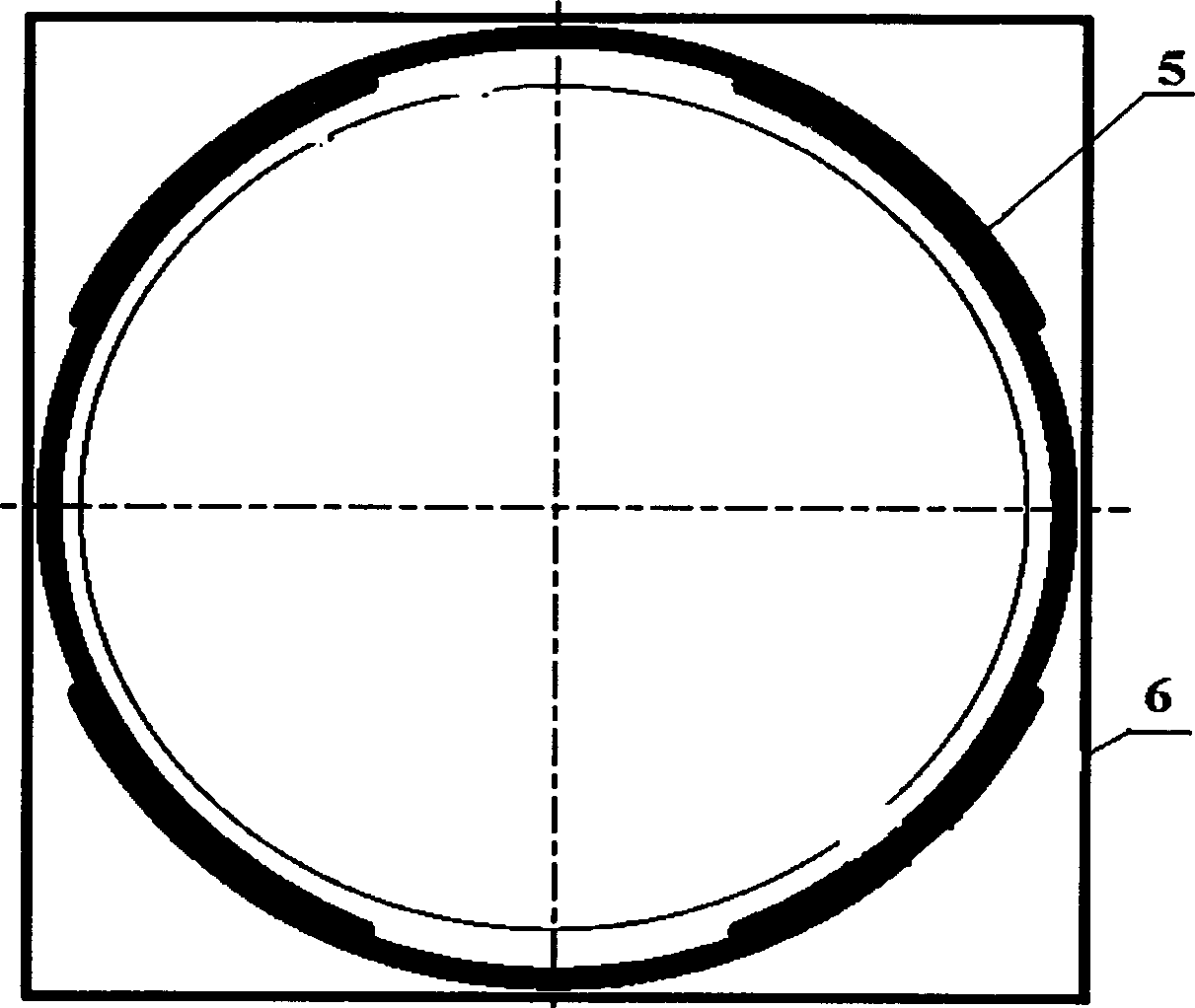

[0024] see Figure 1 to Figure 6 As shown, the present invention includes a metal cylinder conductor 1 and a saddle probe 5, the saddle probe 5 includes a housing 6, a signal line 4 and an excitation coil 3, the housing 6 is arc-shaped, and at the bottom of the housing 6 Both sides are respectively provided with two base chucks 7, and the base chucks 7 are used to fix the saddle-shaped probe 5. A detection coil 2 is respectively arranged on the top of the two base chucks 7, and a detection coil 2 is arranged on the two detection coils 2. There are two detection coils 2 connected in series between them, there are four detection coils 2, two excitation coils 3 are arranged on the upper part of the detection coils, and a signal line 4 is arranged between the two excitation coils 3 . The saddle probe 5 is arc-shaped. The number of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com