Method for manufacturing embedded Si nanocrystalline SONOS device

A device manufacturing method, silicon nanocrystal technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor charge retention, poor durability, and device reliability, and achieve improved interface states and improved Reliability, improved interface effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

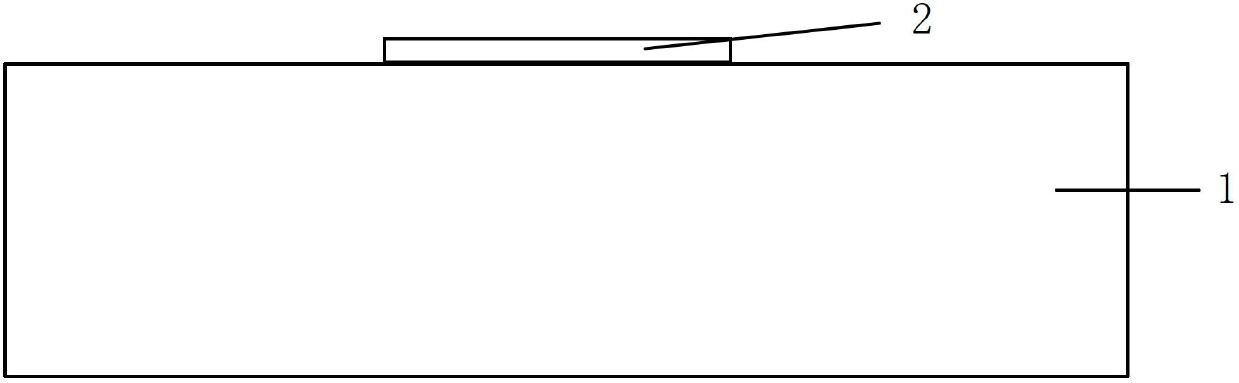

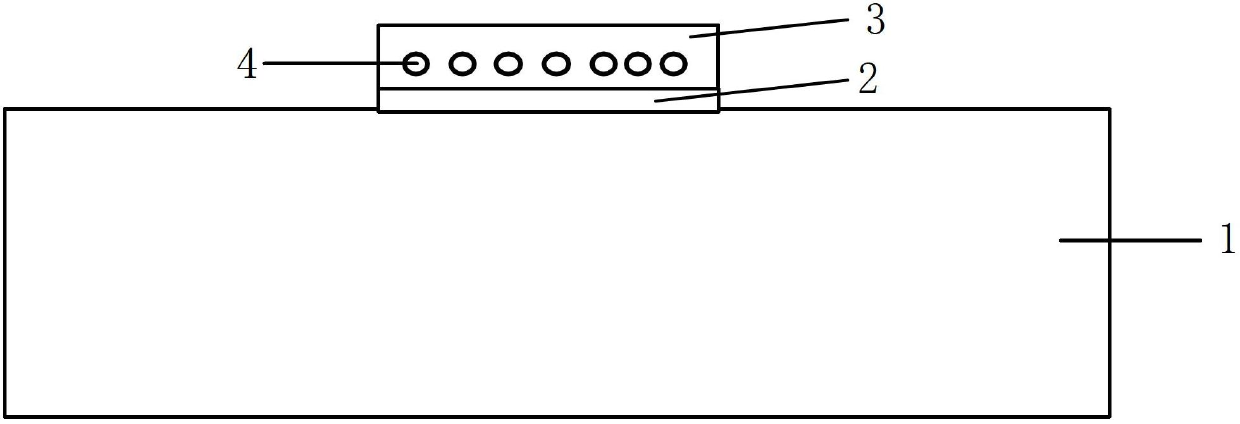

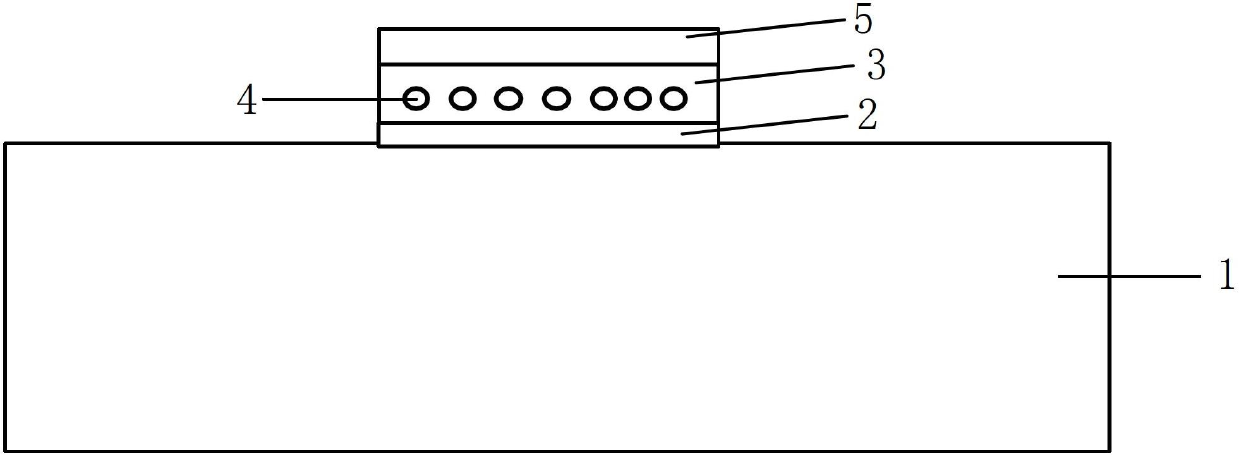

Image

Examples

Embodiment Construction

[0025] The purpose of the present invention is to improve the reliability of the SONOS device through two annealing processes, and perform the first annealing process after forming the first oxide layer to reduce the interface state density at the interface between the substrate and the first oxide layer , while forming a part of Si-N bonds on the surface of the first oxide layer; performing the second annealing after the formation of the second oxide layer can further improve the interface state, and at the same time improve the interface between silicon nanocrystals and silicon nitride, making nanocrystals The interface with silicon nitride is less prone to charge retention during program and erase processes, thereby improving the reliability of embedded nanocrystalline SONOS devices.

[0026] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the following in conjunction with the attached Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com