LED (Light Emitting Diode) integrated packaging substrate with shortest bonding wire and light source module applying substrate

An integrated packaging and substrate technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven light output, difficulty, and large light loss of the light source, and achieve the benefits of optical design, improve light output efficiency, and increase light output rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

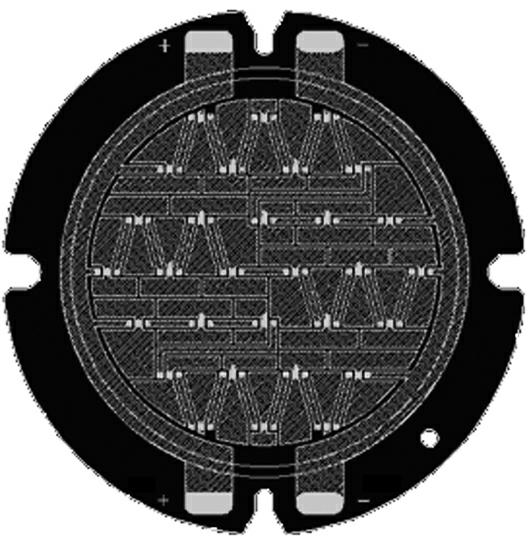

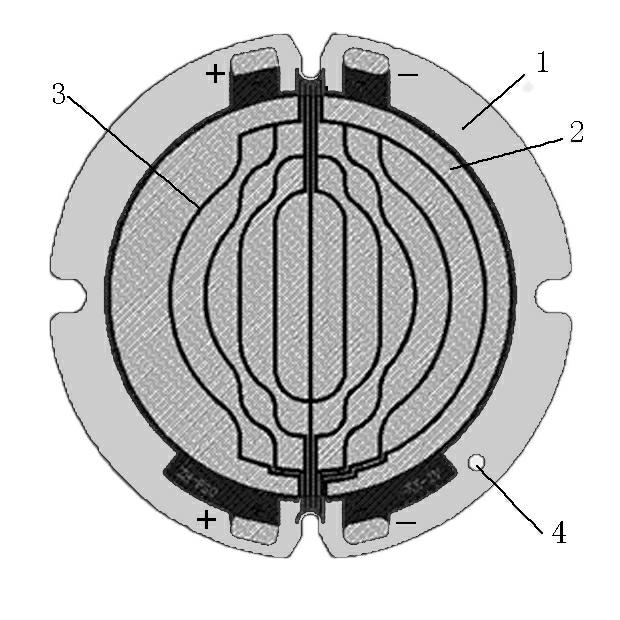

[0030] refer to figure 2 , the LED integrated packaging substrate with the shortest bonding wire in the present invention includes a substrate main body, a common circuit arranged on the substrate main body, and a die-bonding area 2 arranged on the substrate main body, and the die-bonding area 2 is divided into at least two In the integrated area, the public circuit is an integrated metal plate and is arranged correspondingly to the integrated area. Each integrated area corresponds to a common circuit. The common circuits are insulated from each other and have opposite electrodes. The integrated metal plate forms a circuit area. The entire metal plate can be used as the lead pad of the LED chip; any position in the area of the integrated die-bonding area can be used as the bonding position of the LED chip; the integrated die-bonding area can be formed by a circle, a line segment or a Surrounded by any combination of solitary and line segments, the integrated die bonding are...

Embodiment 2

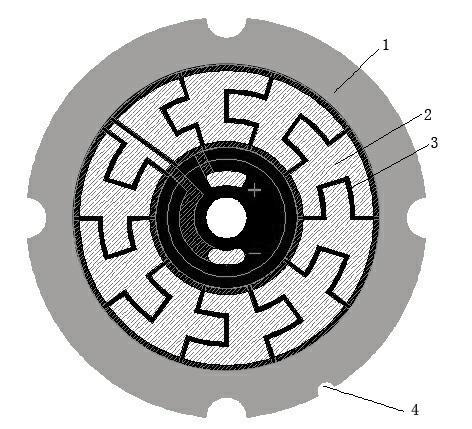

[0035] refer to image 3 , The difference between this embodiment and Embodiment 1 is that the area surrounding the die bonding is surrounded by broken lines, and the fool-proof holes 4 are set as fool-proof grooves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com