Multi-channel parallel optical component for high-speed transmission and assembly method thereof

A technology of high-speed transmission and optical components, applied in the coupling of optical waveguides, etc., can solve problems such as signal transmission distortion and affect communication quality, and achieve the effects of improving capabilities, avoiding parasitic capacitance and inductance, and reducing the length of gold wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

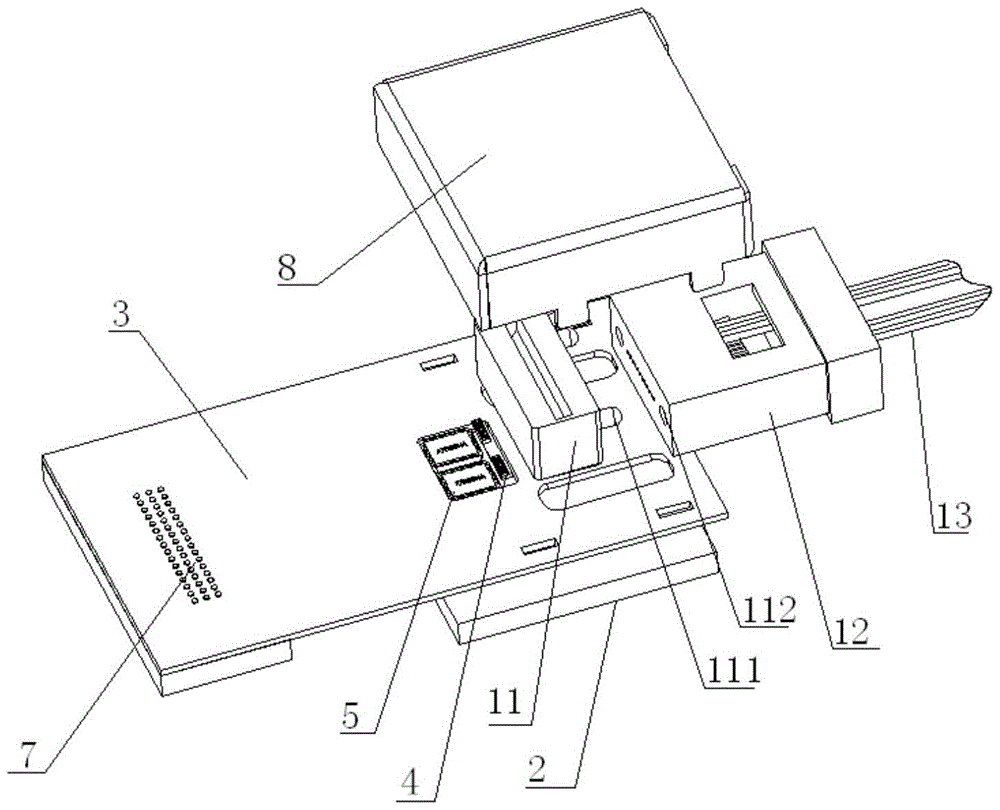

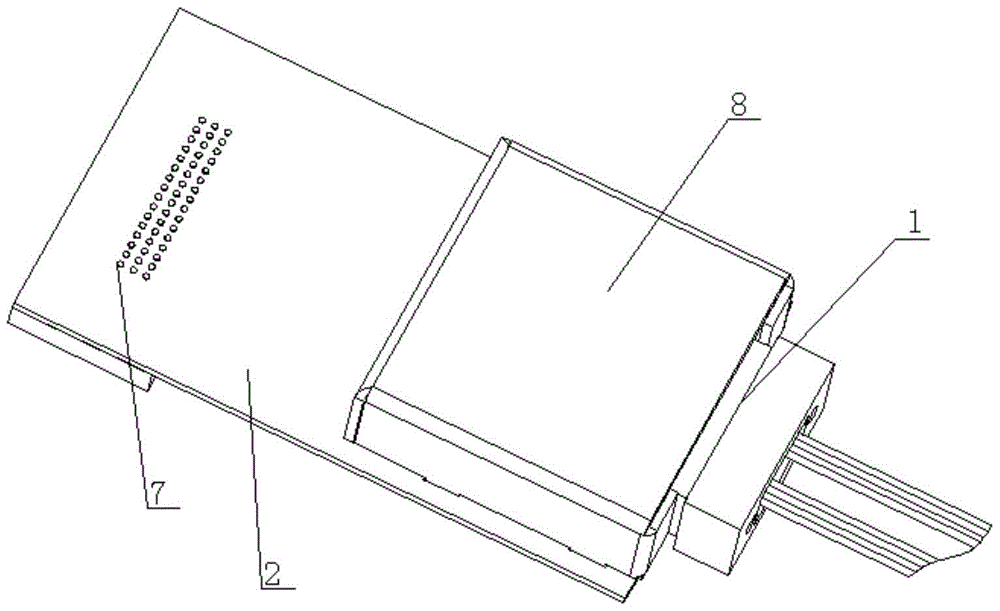

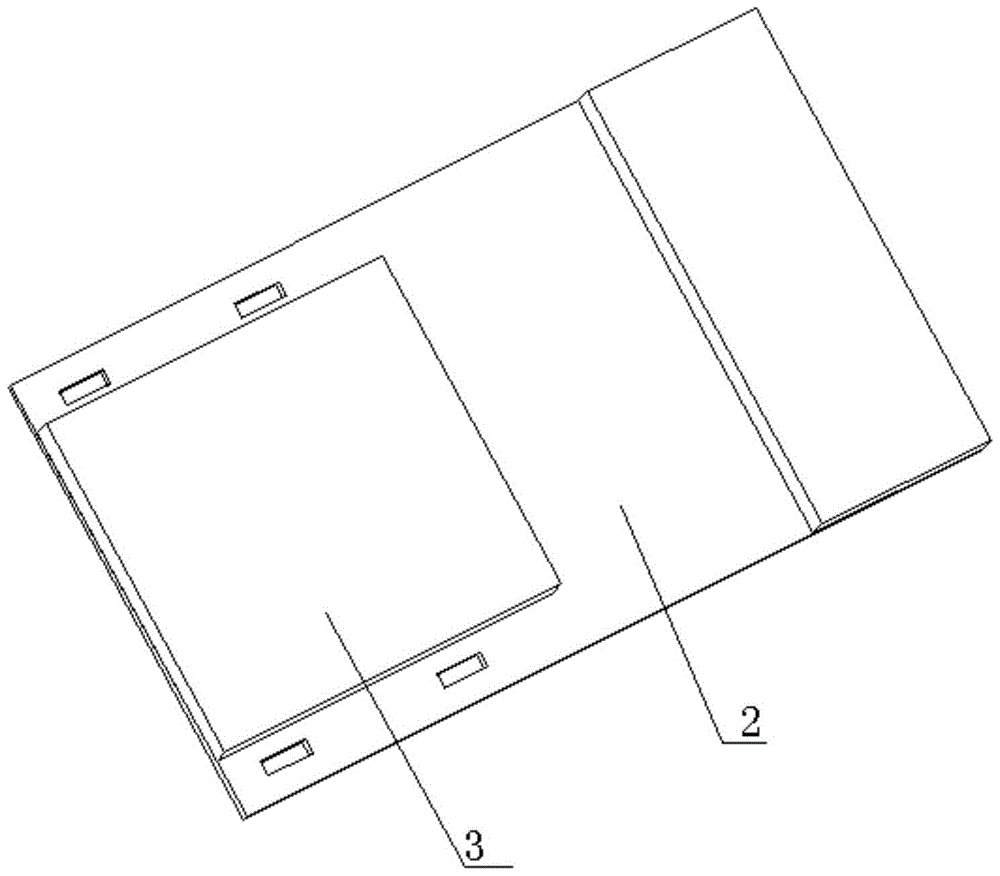

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a multi-channel parallel optical assembly for high-speed transmission includes a parallel optical fiber coupling alignment assembly 1, a backing board 2, a chip carrier 3 (PCB flexible board or hard board), an optoelectronic chip array group 4 (such as a VCSEL chip array or / and PD chip array) and a drive circuit chipset 5 for driving the photoelectric chip array group; the photoelectric chip array group is mounted on the substrate, and the drive circuit chipset is close to the photoelectric One side of the chip array group is mounted on the substrate; the middle part of the chip carrier has a through hole 31 that matches the shape and size of the drive circuit chip group and the optoelectronic chip array group after mounting; The chip carrier is mounted on the backing board, and the photoelectric chip array group and the driving circuit chip group are penetrated in the through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com