Hand-ripped processed cheese and preparation method thereof

A technique of remanufacturing cheese and hand-tearing is applied in the field of remanufacturing cheese and its preparation, which can solve the problem of high fat and achieve the effects of mild flavor and excellent tearability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

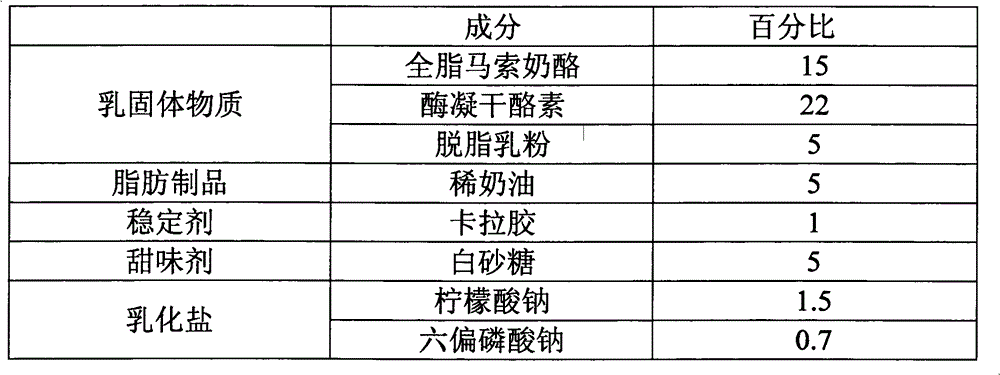

[0066] Raw material formula:

[0067]

[0068]

[0069] Preparation:

[0070] ① According to the above formula, put all the raw materials except cheese and fat products into the melting pot, the number of blades is 2 pieces, and the thickness of the blades is 3mm. Without heating, the temperature was controlled at 20°C, and sheared and stirred at 600rpm for 3 minutes to obtain a premixed slurry;

[0071] ② Add cheese and fat products, stir at 600rpm, heat directly with steam to 82°C, keep warm and stir for emulsification, and keep warm for 8 minutes;

[0072] ③Fill into strips with a radius of 0.5×length 12cm, air-cool to 30°C within 10 minutes, and refrigerate at 4°C after forming.

[0073] After determination, the fat content is 5.3%.

Embodiment 2

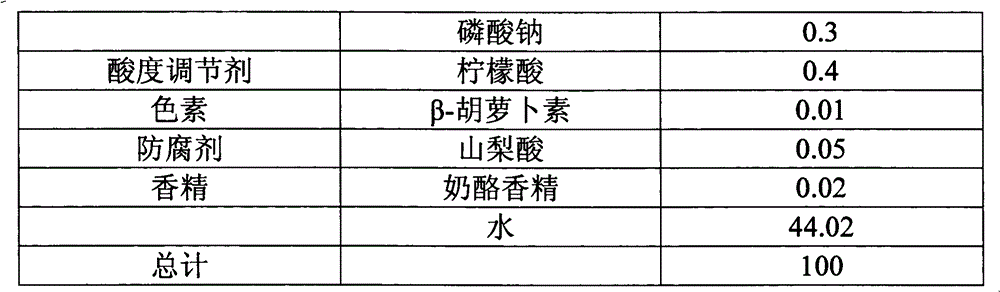

[0075] Raw material formula:

[0076]

[0077]

[0078] Preparation:

[0079] ① According to the above formula, put all the raw materials except cheese and fat products into the melting pot, the number of blades is 3 pieces, and the thickness of the blades is 5mm. Without heating, the temperature was controlled at 25°C, and sheared and stirred at 700 rpm for 3 minutes to obtain a premixed slurry;

[0080] ② Add cheese and fat products, stir at 600rpm, heat directly with steam to 90°C, keep warm and stir to emulsify, and keep warm for 5 minutes;

[0081] ③Fill into strips with a radius of 0.5×8cm in length, air-cool to 35°C within 9 minutes, and refrigerate at 6°C after forming.

[0082] After determination, the fat content was 7.0%.

Embodiment 3

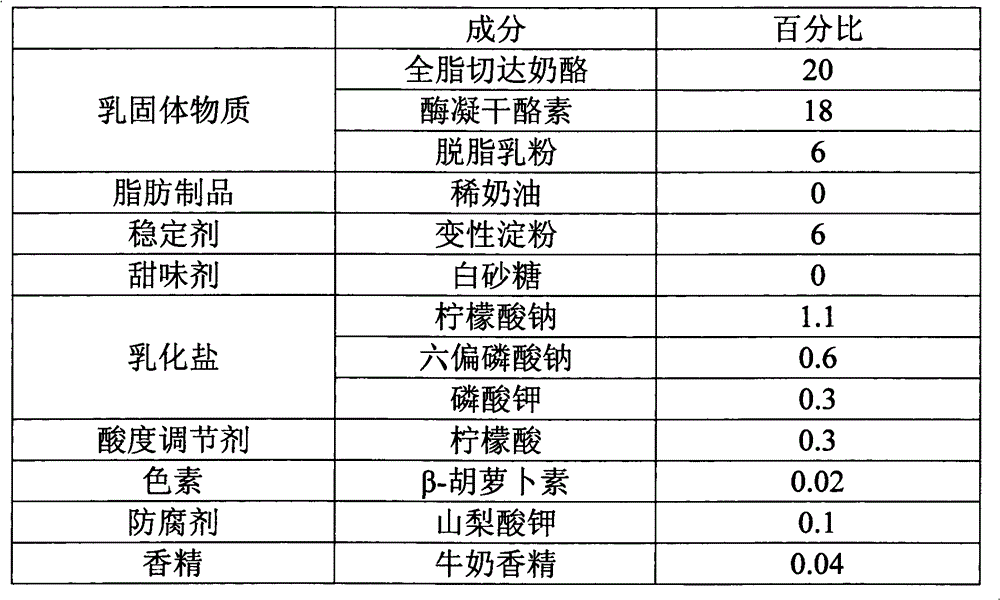

[0084] Raw material formula:

[0085]

[0086] Preparation:

[0087] ① According to the above formula, put all the raw materials except cheese and fat products into the melting pot, the number of blades is 3 pieces, and the thickness of the blades is 5mm. Without heating, the temperature is controlled at 30°C, and the premixed slurry is obtained by shearing and stirring at 100 rpm for 4 minutes;

[0088] ② Add cheese and fat products, stir at 100rpm, heat directly with steam to 95°C, keep warm and stir to emulsify, and keep warm for 6 minutes;

[0089] ③Fill into long strips with a radius of 0.5×10cm in length, water-cool to 25°C within 8 minutes, and refrigerate at 8°C after forming.

[0090] After determination, the fat content was 5.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com