Safe freshness-keeping storage and processing method for chestnuts

A processing method, chestnut technology, applied in food preservation, food science, food preparation, etc., can solve the problems of internal quality decline, wounds are easy to rot, and the quality of chestnut products cannot be guaranteed, so as to achieve the effect of low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

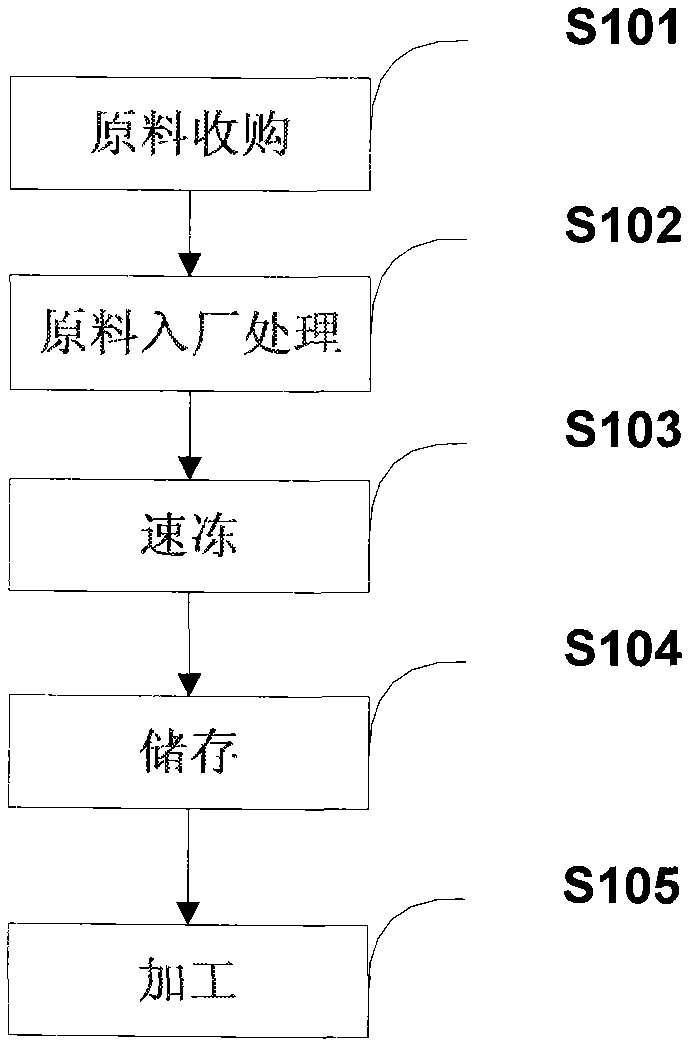

[0018] figure 1 It shows the implementation flow of the chestnut safe fresh-keeping storage and processing method provided by the embodiment of the present invention. Specific steps are as follows:

[0019] S101: Purchase of raw materials. Bulk raw materials are graded with grading sieves when purchased at the origin, and purchased according to grades, and at the same time arrange people to initially pick out the moth-eaten fruit and black-headed fruit;

[0020] S102: Raw materials enter the factory for processing. For the raw materials for processing blanched chestnuts and canned food in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com