Foaming process for cakes

A process and cake technology, applied in the direction of food forming, food science, application, etc., can solve the problems of high labor intensity, affecting the taste of products, and difficult to stabilize product quality, so as to reduce production costs, maintain good quality, and achieve high production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

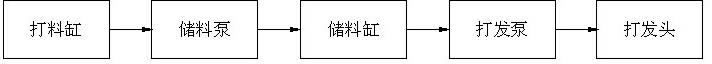

[0012] As shown in the figure, a cake foaming process is characterized in that it is carried out in the following manner: (1) Put eggs, malt syrup, white sugar, salt, glycerin, and sorbitol into the mixing tank of the whipping machine , stir for 3 minutes at a slow speed, and stir for 3 minutes at a fast speed; (2) Put the flour into the mixing tank and stir for 4 minutes at a slow speed; (3) Put the oil into the mixing tank and stir for 1 minute at a slow speed until the slurry is evenly mixed ; (4) Use the delivery pump to transport the slurry obtained in step (3) to the storage tank of the sender through the storage pump, and pass circulating water into the interlayer of the storage tank to keep the temperature of the storage tank at 20 degrees Celsius (5) Use the sending pump to transport the slurry in the storage tank to the sending head at a rate of 12Hz, and the rotor on the sending head rotates at a rate of 30Hz to send the slurry, and the total air pressure of the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com