Cleaning device with double cross-flow fans, three air passages and double-layered vibrating screens

A cross-flow fan and cleaning device technology, which is applied in the direction of filtering, separating solids from solids with airflow, and solid separation, which can solve low cleaning efficiency, high cleaning loss rate, and uneven airflow on the screen surface and other problems, to achieve the effect of improving cleaning efficiency, efficient screening and cleaning, and increasing the speed of sieving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

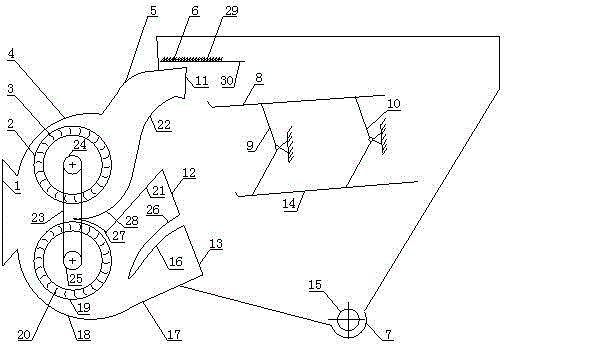

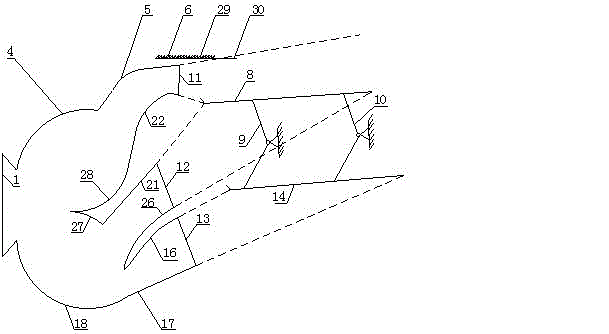

[0021] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] The utility model relates to a cleaning device of a double-through flow fan, three air ducts, and a double-layer vibrating sieve, which includes a feeding mechanism, a screening mechanism, a winnowing mechanism, and a grain conveying mechanism.

[0023] The feeding mechanism includes a stepped shaking plate 6, sawtooth 29 and finger-shaped sieve 30. The stepped shaking plate 6 is equipped with sawtooth 29 banners, and a finger-shaped sieve 30 is provided at the end of the stepped shaking plate 6; the screening mechanism includes an upper vibrating screen. 8. The lower vibrating screen 14, the front driving rocker 9 and the rear driving rocker 10, the front driving rocker 9 and the rear driving rocker 10 drive the upper vibrating screen 8 and the lower vibrating screen 14; Cross-flow fan 2, bottom cross-flow fan 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com