Full-symmetrical type five-axis cutter sharpener

一种刀具磨床、全对称的技术,应用在磨床、磨削床身、磨削机床的部件等方向,能够解决影响加工精度、传动部分热变形等问题,达到降低加工误差、便于误差补偿、提高结构稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

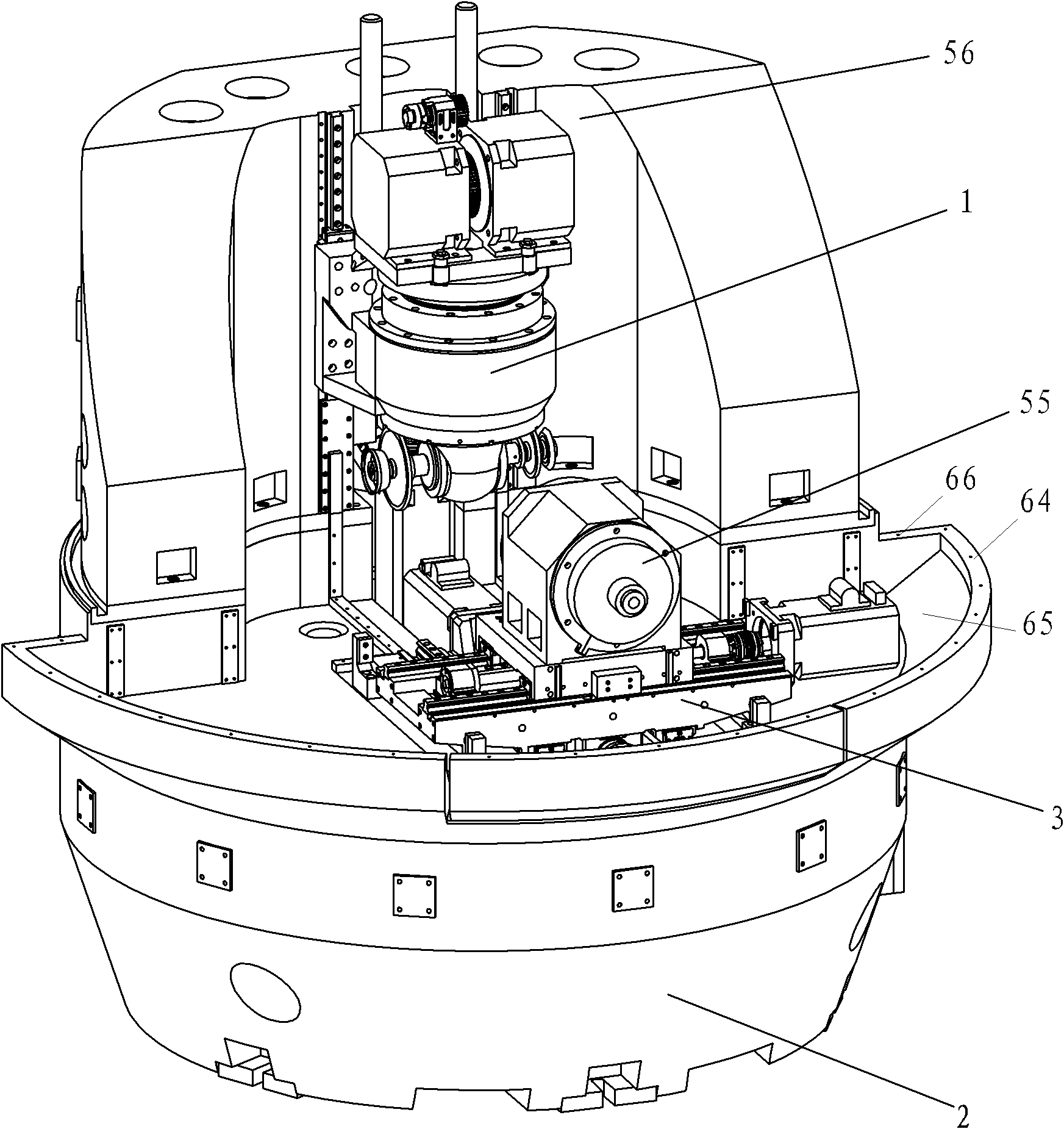

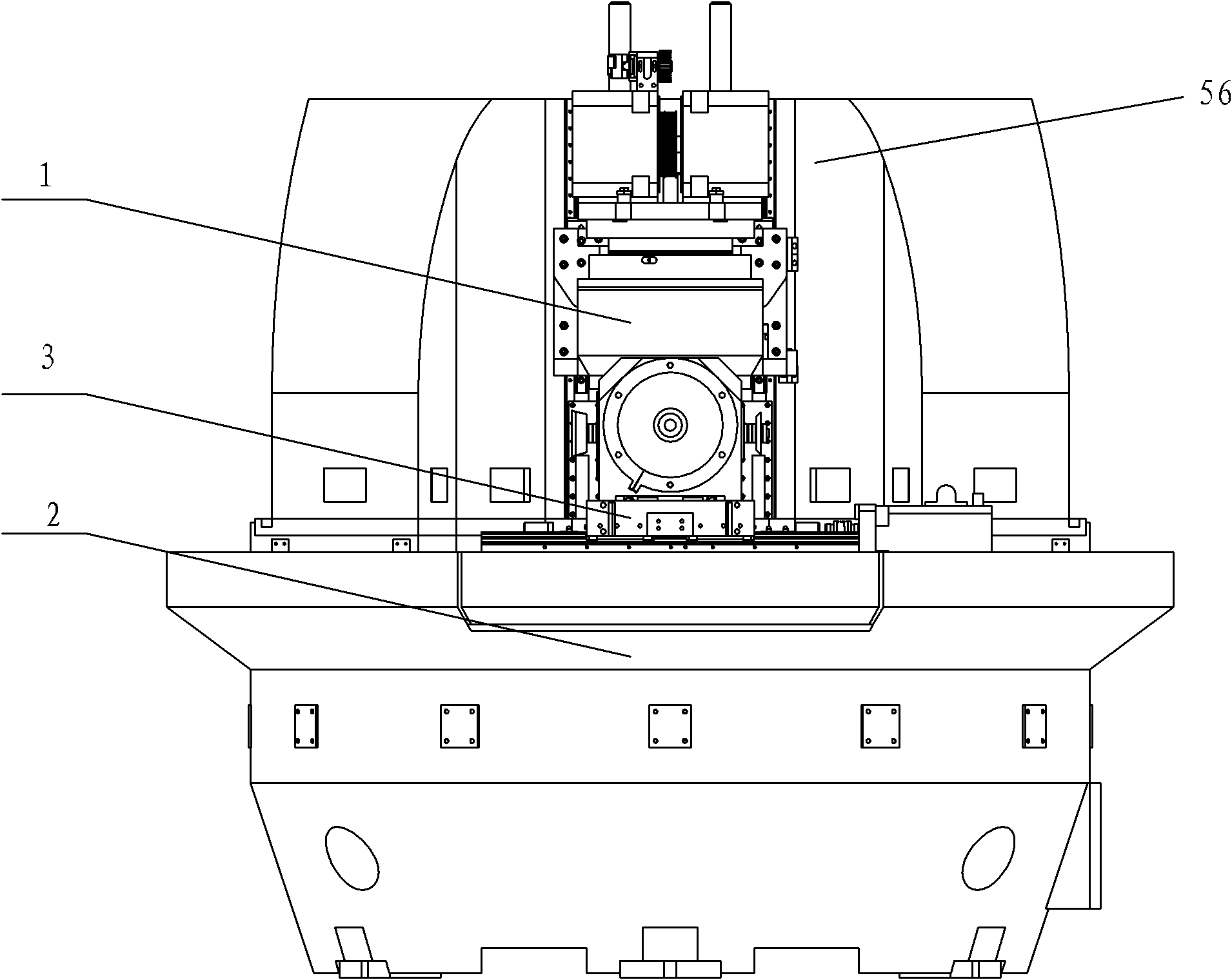

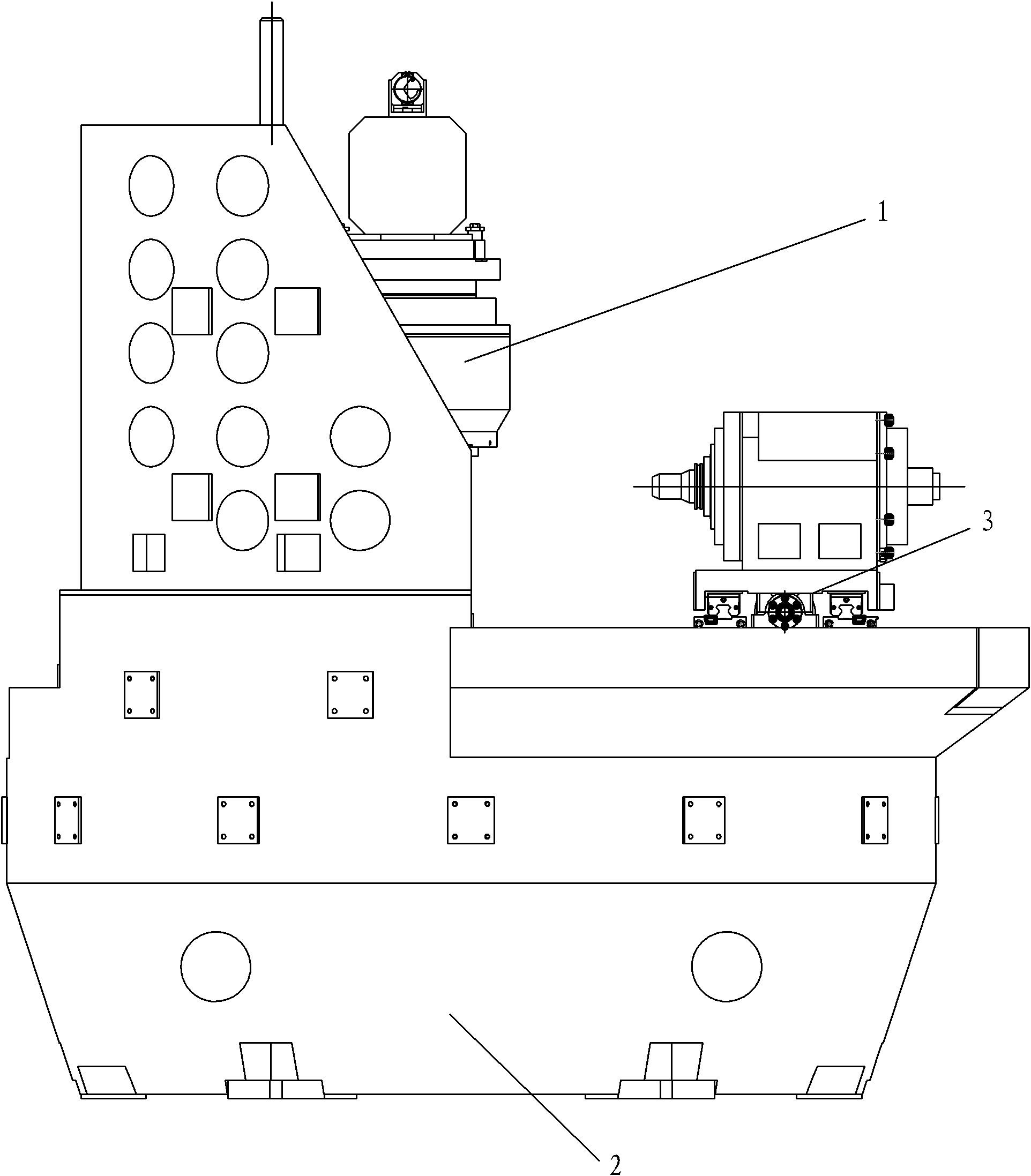

[0020] Such as Figure 1-4 The fully symmetrical five-axis tool grinder of the present invention shown includes a grinder base 2 and a column 56 on one side of the grinder base 2. figure 1 Among them, the upper part of the grinder base 2 is the surface of the worktable, and is provided with a cross sliding table 3 and a clamp seated on the sliding table 3 for clamping the workpiece to be ground. figure 2 In the vertical surface of the column 56, a slide rail 4 is vertically installed; the slide rail 4 is provided with a grinding wheel head frame 1, which can slide up and down on the slide rail 4 and stop at the working position that requires grinding processing as required . Specifically, two bearing seats are installed vertically on the column, and a lead screw is connected in series between the two bearing seats. The two bearing seats support both ends of the lead screw. The lead screw is equipped with a lead screw nut. On the grinding wheel head frame, the lower end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com