Fastening system

A technology for fixing systems and fixing components, which can be used in threaded fasteners, light impact tools, turning equipment, etc., and can solve problems such as thread damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

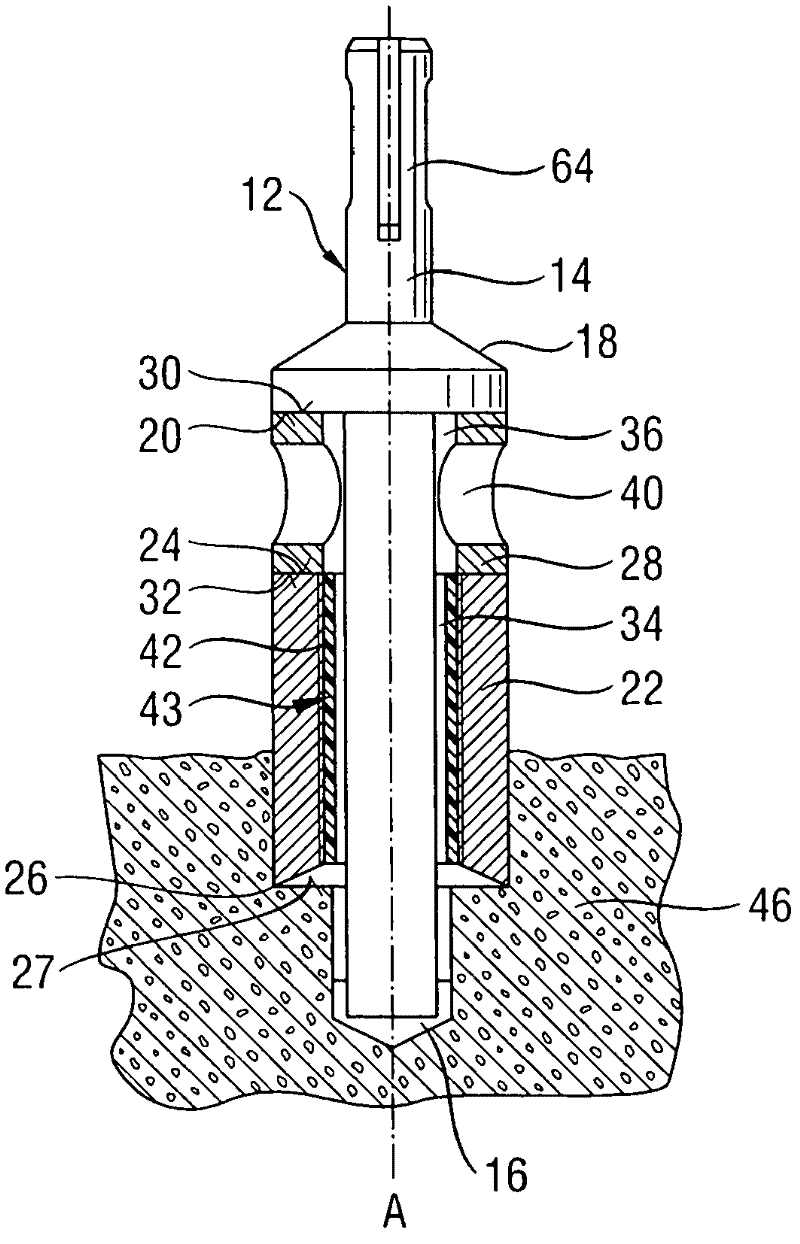

[0038] figure 1 A fastening system 10 is shown with a drill head 12 having a drill rod 14 and a drill tip 16 . A radially protruding shoulder 18 is formed on the drill rod 14 in the upper section, which shoulder has a substantially horizontal impact surface 20 facing the drill point 16 .

[0039] Arranged below the impact surface 20 is a fastening element 22 which is sleeve-shaped and surrounds the drill rod 14 concentrically, and has an essentially horizontal impact surface 24 facing the impact of the shoulder 18 . Surface 20. Both impact surfaces have a deviation from perpendicular to the axial direction A of at most 3°.

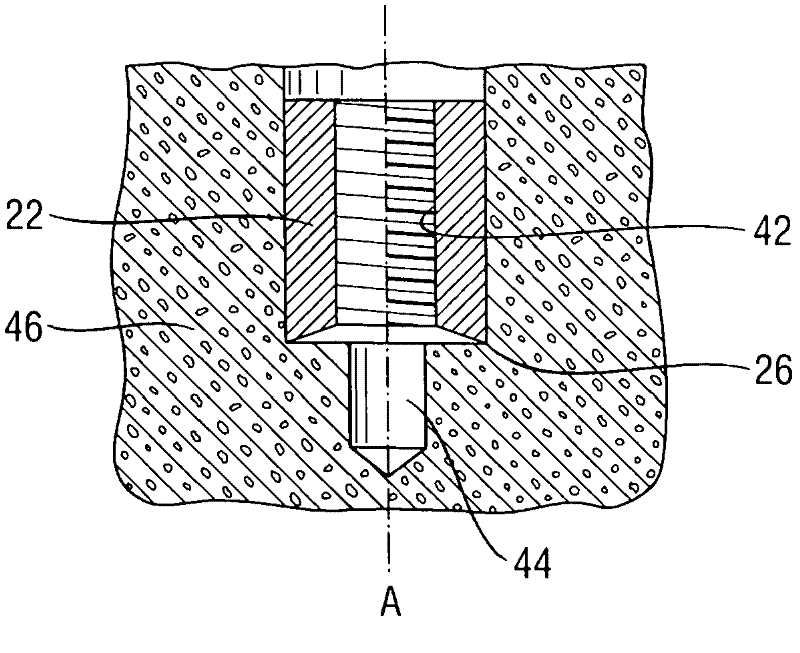

[0040] At the axial end facing away from the impact surface 24 , the fastening element 22 has a cutting edge 26 that is as sharp as possible. A front disintegration surface 27 of the disintegration base material adjoins radially inwardly on the cutting edge 26 .

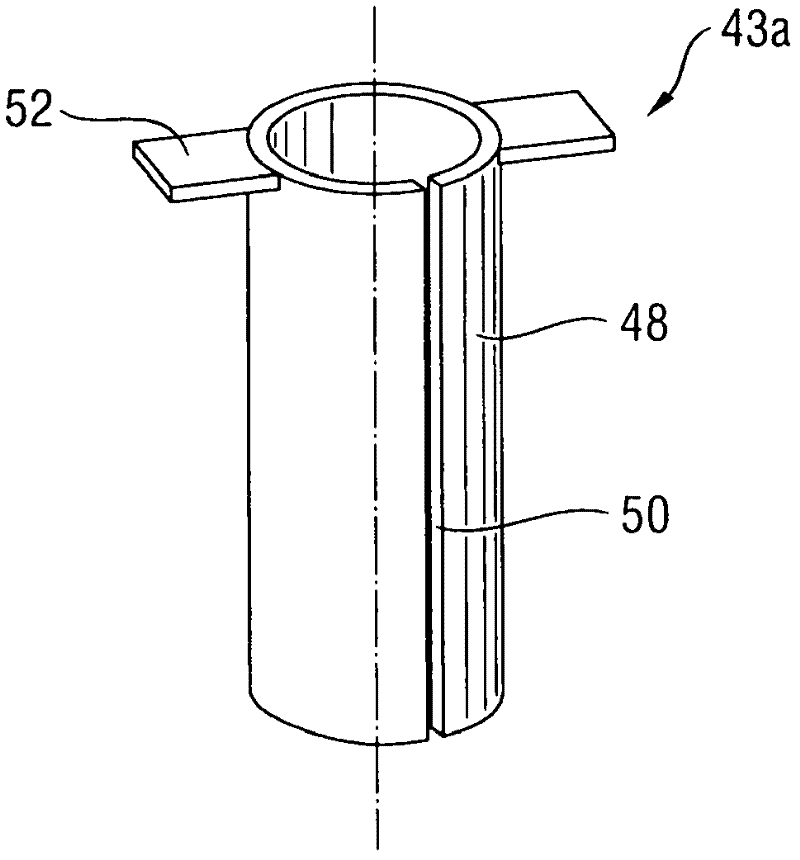

[0041] The fastening element 22 is formed here from a material in which at least the impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com