Conveying type plant automatic production equipment and method

An automatic production and conveying technology, applied in botany equipment and methods, soilless cultivation, cultivation, etc., can solve the problems of failing to achieve production line, large planting area, and relying on labor, etc., to achieve practical environmental protection, practical health safety, saving arable land, zero pollution, practical and healthy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

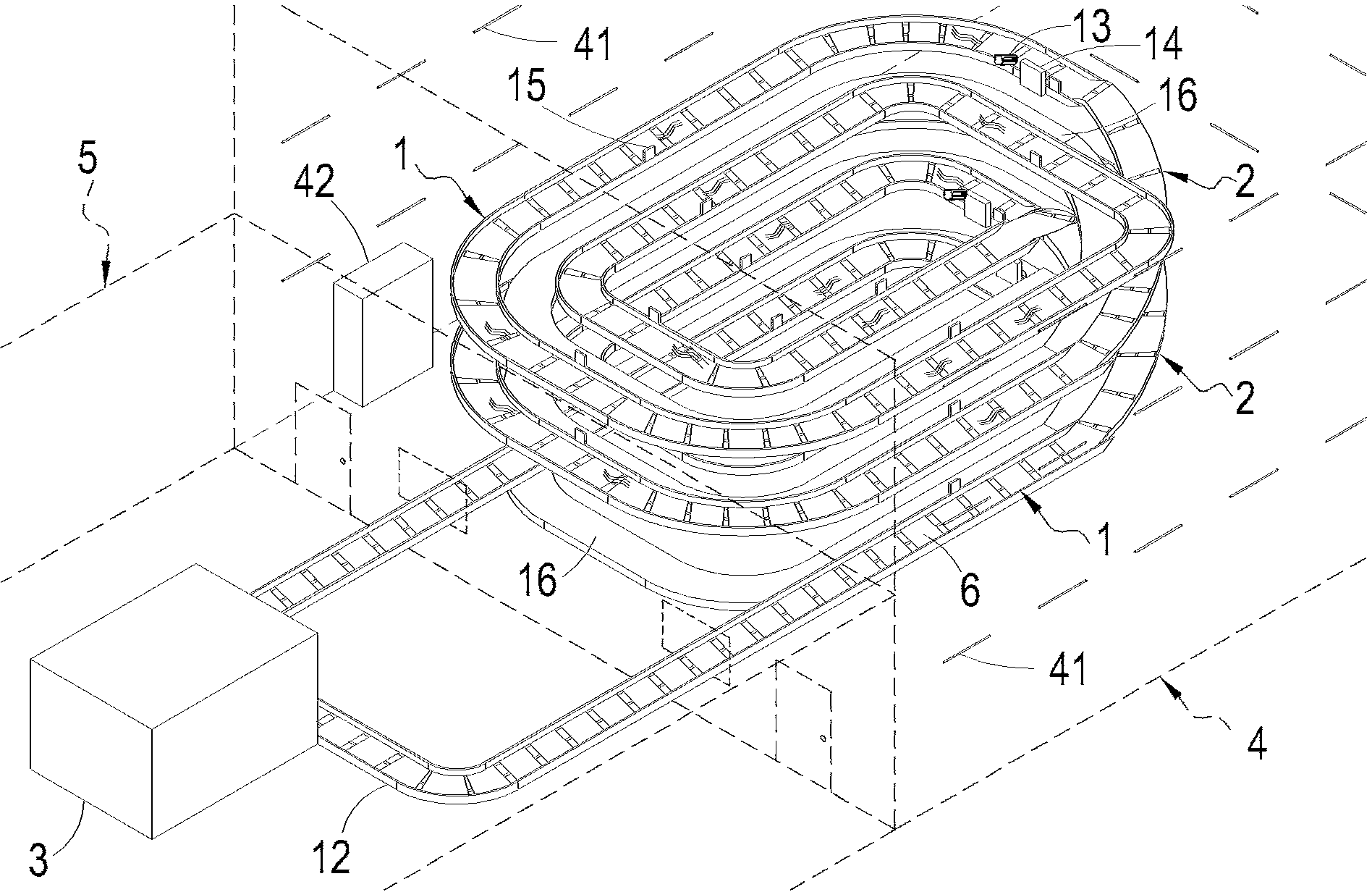

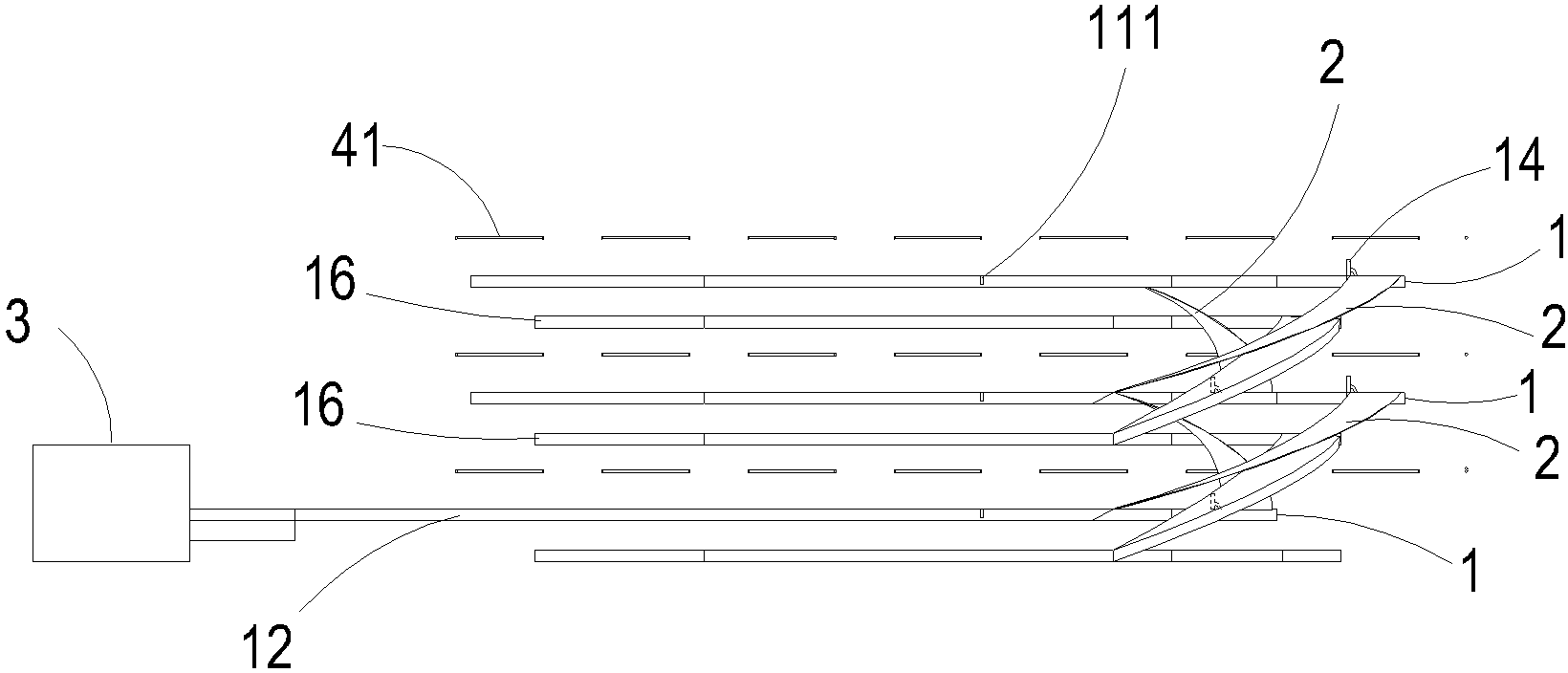

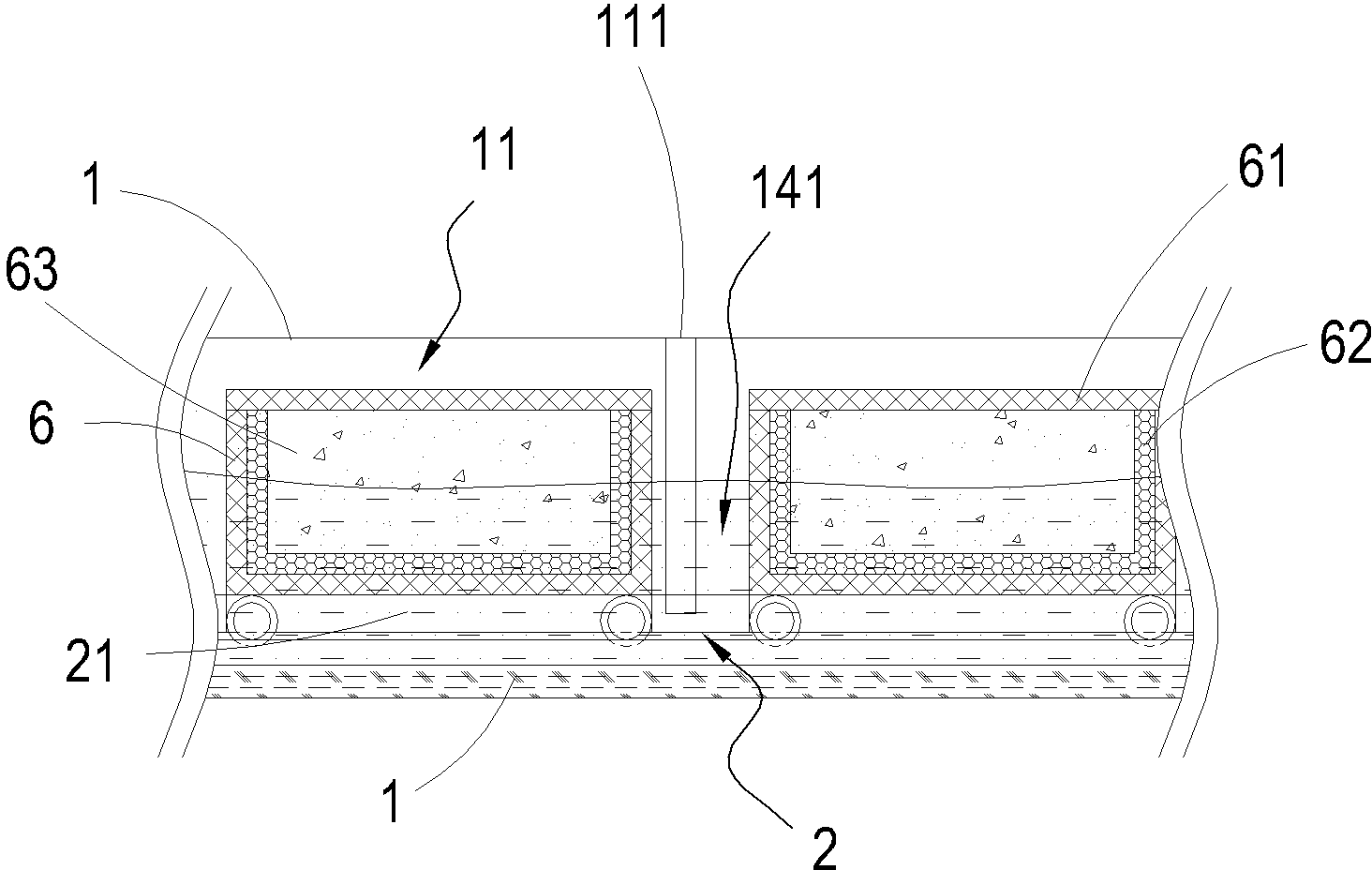

[0044] as attached figure 1 to attach Figure 4 As shown, it is a schematic illustration of the implementation of the preferred embodiment of the present invention Figure 1 , implementation instructions Figure II , partial indication Figure 1 and partial indication Figure IIIt can be clearly seen from the figure that the present invention includes at least one surrounding tray group 1 and at least one circulation transmission module 2, and the tray group 1 is stacked in three layers in an approximately rectangular shape in this embodiment, and the ring is set Two circles are embodiments, and the above-mentioned tray group 1 is only one of the embodiments, and its shape, quantity and style are not limited to this, and at least one maintenance walkway 16 is provided at the side of the tray group 1, and the tray group 1 is set In a greenhouse 4, and the greenhouse 4 includes at least one lamp 41 and at least one dry and wet temperature sensing control device 42, and at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com