Honeycomb type denitration catalyst and preparation method thereof

A denitration catalyst and honeycomb technology, which are applied in the field of honeycomb denitration catalyst and its preparation, can solve the problems that the denitration capacity of the catalyst is depended on and the preparation parameters are closely related, and achieve the effects of good high temperature resistance, high denitration activity and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

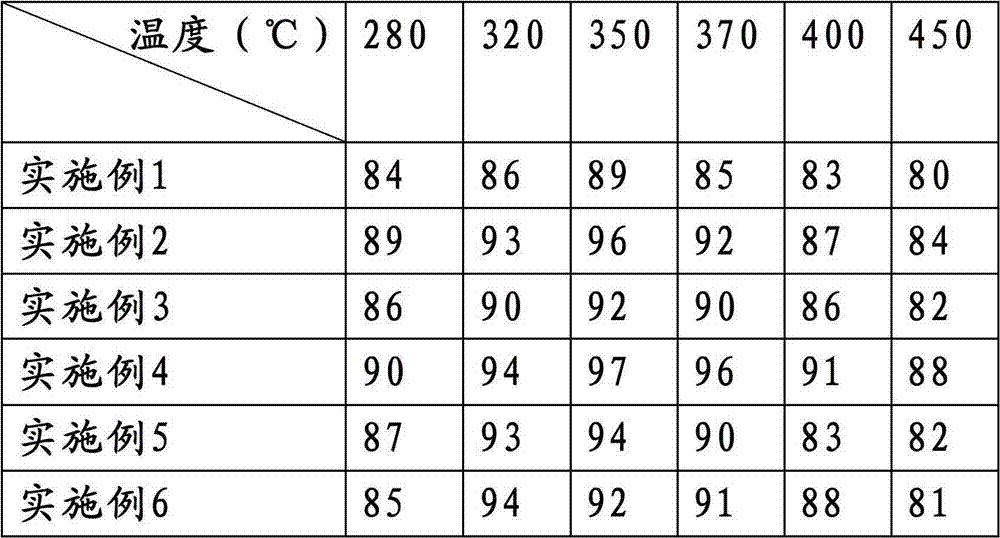

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in combination with specific embodiments.

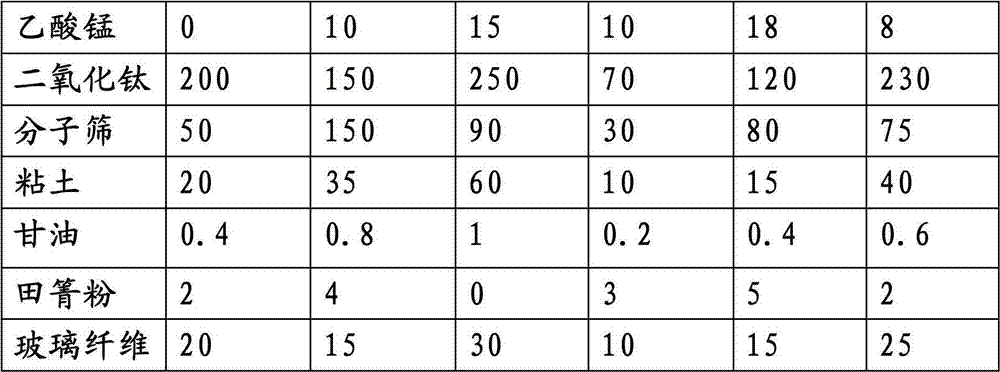

[0024] material selection

[0025] The active component of the catalyst is ferrous sulfate, or ferrous sulfate and manganese acetate.

[0026] The solvent can be water or deionized water, or other suitable solvents. In view of cost, it is preferable to use water as the solvent.

[0027] The catalyst carrier adopts anatase nano-titanium dioxide and molecular sieve. Molecular sieves may include A-type zeolite molecular sieves, X-type zeolite molecular sieves, Y-type zeolite molecular sieves, ZSM series molecular sieves, MFI molecular sieves, MOR molecular sieves, and the like.

[0028] Auxiliaries may include binders, extrusion aids and / or reinforcing agents, among others.

[0029] As the binder, clay is preferably used.

[0030] The extrusion aid preferably includes glycerin, and more preferably, the extrusion aid also includes Tianqing powder. In other embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com