Concurrent flow type double-hearth limekiln

The double-chamber lime kiln and the technology of the double-chamber kiln are applied in the field of lime kiln and parallel-flow double-chamber lime kiln, which can solve the problems of increasing the energy consumption of lime production, endangering the safety of the environment, and preventing the pressure of the fan from being held back, so as to be beneficial to the environment. Protection, pollution reduction, fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings.

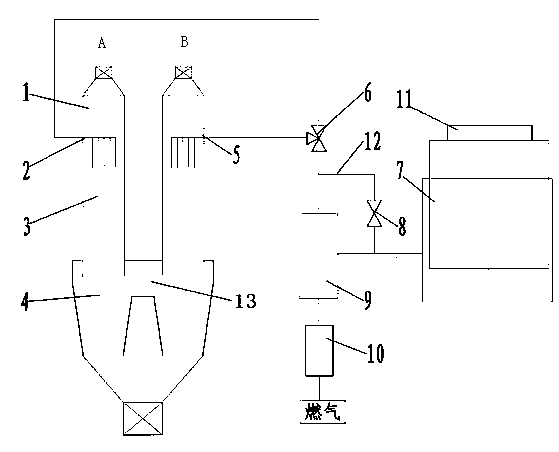

[0011] The present invention parallel-flow double chamber lime kiln such as figure 1 As shown, it includes a double chamber kiln body, feeding equipment, discharging equipment, air supply system, fuel supply system and exhaust gas discharge system. Each side of the kiln body is equipped with a preheating zone 1, a calcination zone 3 and a cooling zone 4. A connecting channel 13 is provided at the bottom of the calcining zone of the kiln bodies on both sides (kiln body A and kiln body B), and the kiln body A and kiln body B are connected through the connecting channel 13 . The calcining zones of kiln body A and kiln body B are provided with burners 2 and 5, and the burners are plug-in burners. The fuel supply system is provided with a reversing device 9 and a reversing storage tank 7, and the storage tank is a floating roof tank. The inlet of the reversing device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com