Method utilizing microwave technique to induce modified ardealite

A phosphogypsum and modification technology, applied in the field of using microwave technology to induce modification of phosphogypsum, can solve problems such as no breakthrough research on phosphogypsum, achieve good economic benefits, environmental and social benefits, broaden utilization channels, and save energy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

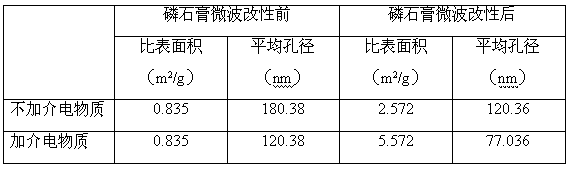

Examples

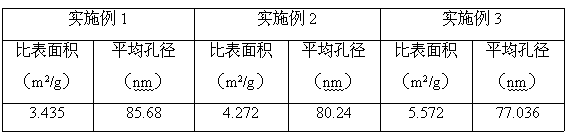

Embodiment 1

[0026] Ball mill 100g of phosphogypsum to 160 mesh, then add 10g of inorganic metal oxide Fe 2 After mixing O, place it under the conditions of microwave frequency 2350MHZ, power 750w, and temperature 100°C for 10 minutes, then cool naturally to room temperature to obtain microwave-induced modified phosphogypsum.

Embodiment 2

[0028] Ball mill 100g of phosphogypsum to 180 mesh, then add 5g of inorganic metal oxide Al 2 o 3 After mixing, microwave treatment was performed under the conditions of microwave frequency 2350MHZ, power 850w, and temperature 120°C for 12 minutes, and then naturally cooled to room temperature to obtain microwave-induced modified phosphogypsum.

Embodiment 3

[0030] Ball mill 100g of phosphogypsum to 200 mesh, then add 2.5g of inorganic metal oxide Al 2 o 3 After mixing, microwave treatment was carried out under the conditions of microwave frequency 2350MHZ, power 950w, and temperature 150°C for 15 minutes, and then naturally cooled to room temperature to obtain microwave-induced modified phosphogypsum.

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com