Phase change modified asphalt and preparation method thereof

A modified asphalt and phase change technology, which is applied in building components, building insulation materials, buildings, etc., to achieve the effects of maintaining ecological balance, simple preparation, and controlling high-temperature diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

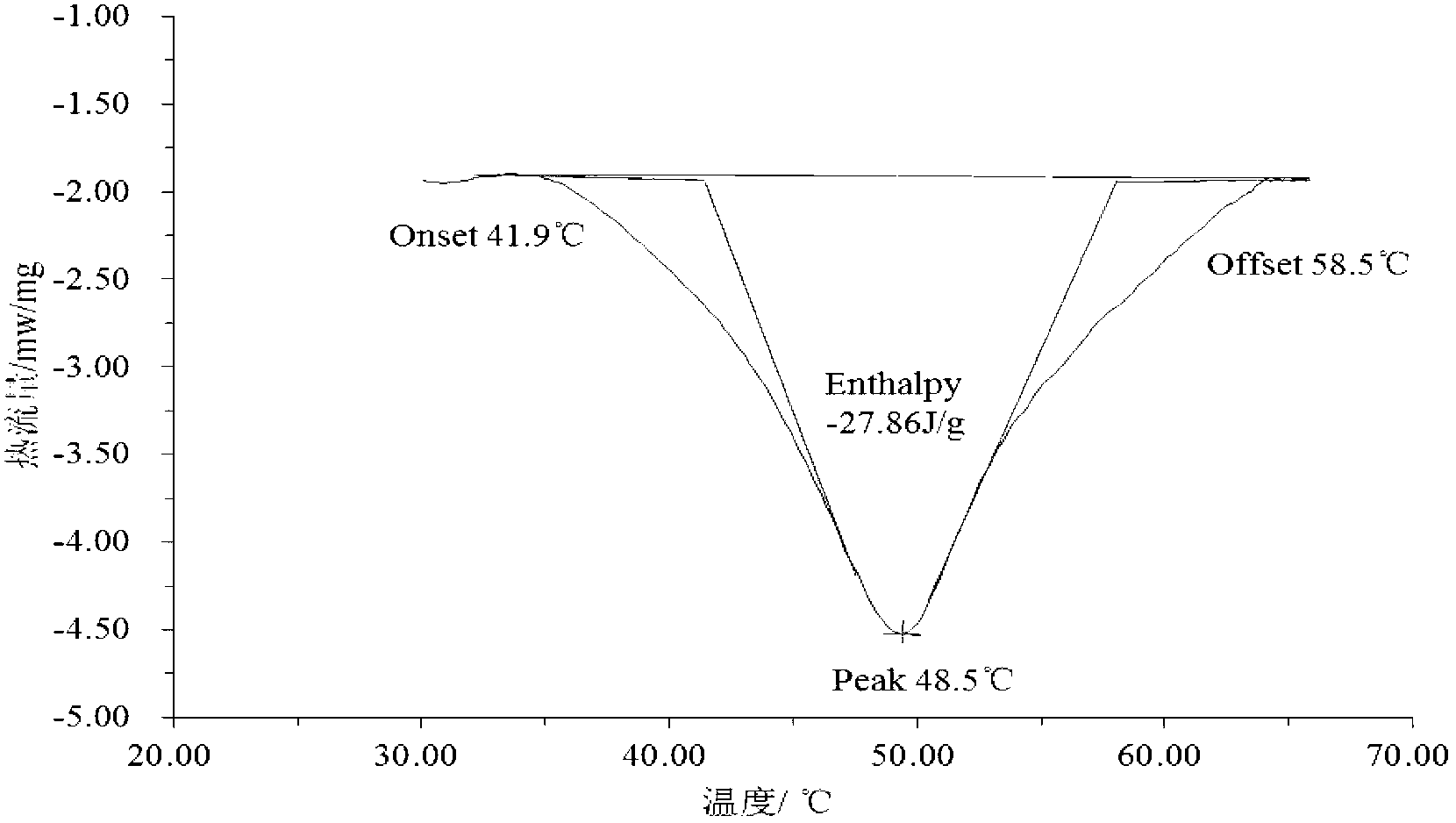

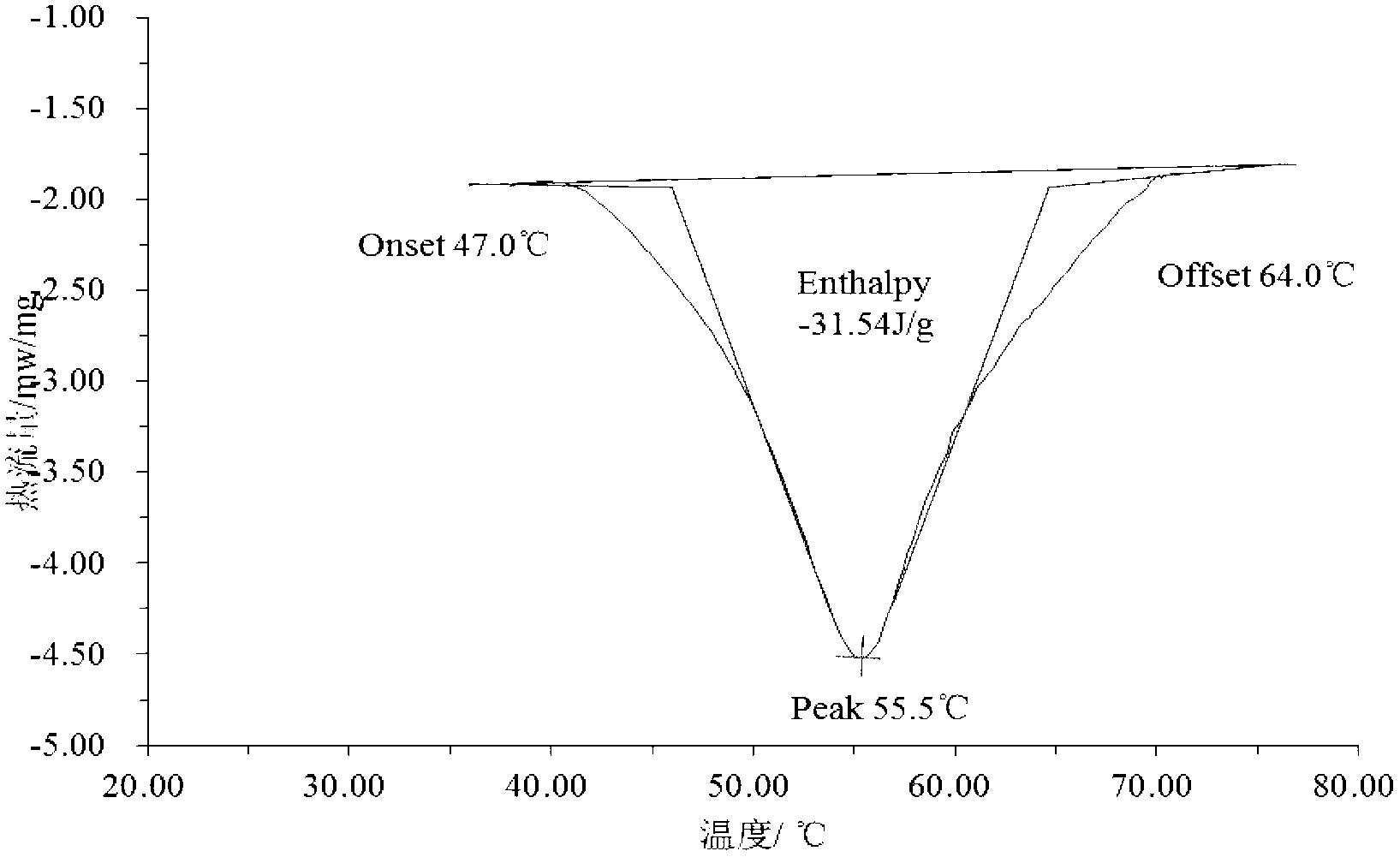

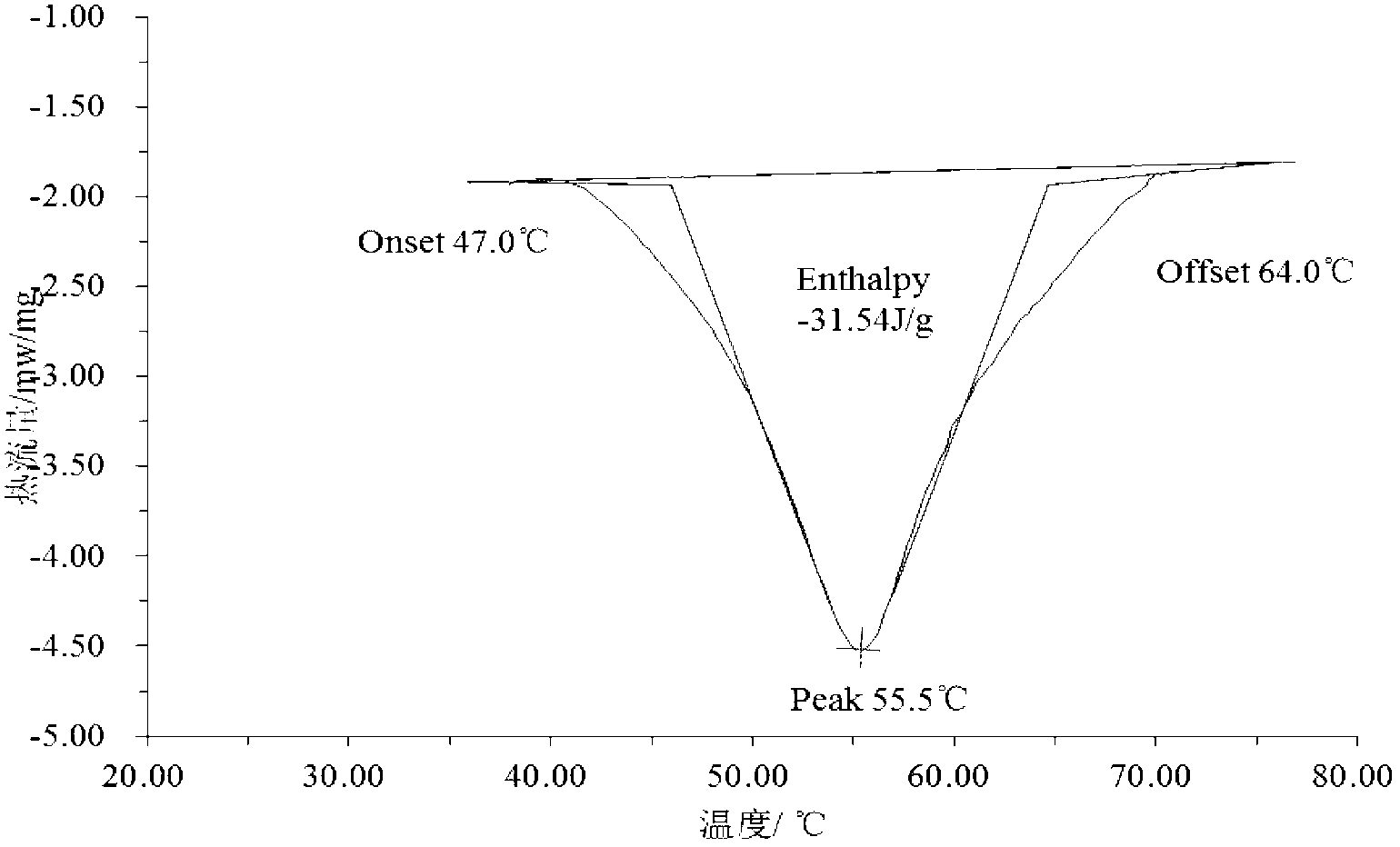

[0016] Embodiment 1: A phase-change modified asphalt in this embodiment is composed of 7-8 parts of asphalt and 2-3 parts of organic phase-change materials in parts by weight.

[0017] This embodiment utilizes the "peak-shifting and valley-eliminating" effect of phase change materials to adjust the temperature field of the asphalt pavement, reduce the possibility of high-temperature rutting, and achieve the purpose of effectively controlling high-temperature diseases of the asphalt pavement. At the same time, it has a certain control effect on the urban "heat island effect", reduces environmental pollution, and maintains ecological balance. The phase change modified asphalt for pavement prepared by this embodiment has a reversible phase change process, a phase change temperature between 40°C and 75°C, and a phase change latent heat greater than 25J / g. The material has a large phase change latent heat, is non-toxic, and has no corrosion properties, and simple preparation.

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is different from Embodiment 1 in that: the asphalt is base asphalt or modified asphalt. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0019] Embodiment 3: This embodiment is different from Embodiments 1 to 2 in that: the organic phase change material is myristic acid, PEG4000 or palmitic acid. Others are the same as the specific embodiment 1 to 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com