Diesel anti-condensation agent

An anti-coagulation agent and diesel technology, applied in the field of fuel additives, can solve the problems of low temperature fluidity, less dosage, lowering the freezing point and cold filter point of diesel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

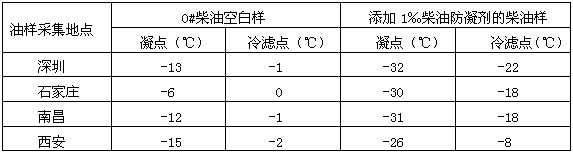

Image

Examples

Embodiment 1

[0017] A diesel anticoagulant, each component and mass percentage:

[0018] Olefin copolymer 30%

[0019] Polyether amine salt 10%

[0020] Mononitrate 15%

[0022] Preparation process: According to the above-mentioned mass percentage, add each material in turn in the stirred tank, stir evenly, and promptly make the diesel oil anticoagulant of the present invention.

Embodiment 2

[0024] A diesel anticoagulant, each component and mass percentage:

[0025] Olefin copolymer 40%

[0026] Polyether amine salt 5%

[0027] Mononitrate 13%

[0028] Dialkenylsuccinimide 5%

[0029] Xylene 10%

[0030] Naphtha 27%.

[0031] Preparation process: According to the above-mentioned mass percentage, add each material in turn in the stirred tank, stir evenly, and promptly make the diesel oil anticoagulant of the present invention.

Embodiment 3

[0033] A diesel anticoagulant, each component and mass percentage:

[0034] Olefin copolymer 35%

[0035] Polyisobutylene amine salt 10%

[0036] Polynitrates 8%

[0037] Monoalkenylsuccinimide 12%

[0038] Xylene 10%

[0040] Preparation process: According to the above-mentioned mass percentage, add each material in turn in the stirred tank, stir evenly, and promptly make the diesel oil anticoagulant of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com