A kind of compression ignition engine vehicle exhaust gas cleaning agent and its preparation and use method

A technology for combustion engines and automobile exhaust, applied in fuel additives, fuels, liquid carbon-containing fuels, etc., can solve problems such as single function, inconvenient use of detergents, corrosiveness, etc., to achieve changes in ignition performance and good biodegradation performance and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

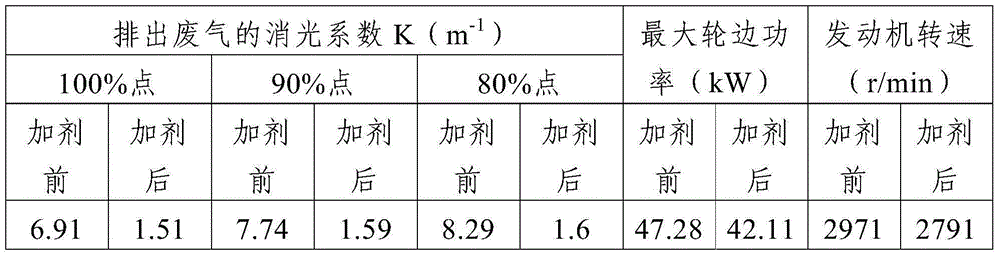

Embodiment 1

[0032] The present embodiment compression ignition type engine automobile tail gas cleanser is made by the raw material of following mass percent: ethanol 6%, polymethoxyl formal 15%, diethylene glycol alkyl ether 0.1%, stabilizing agent 24%, ten Hexane number improver 3%, power lubricant 0.3%, smoke clearing agent 0.5%, the balance is methanol, the power lubricant is a mixture of dimethyl carbonate, fatty acid methyl ester and fatty acid ethyl ester, the diethyl Glycol alkyl ether is one or more of diethylene glycol monohexyl ether, diethylene glycol dimethyl ether and diethylene glycol monooctyl ether, and the smoke clearing agent is barium petroleum sulfonate, cyclic One or more of barium alkanoate, iron naphthenate and quaternary ammonium salt, the quaternary ammonium salt is dodecyl dimethyl benzyl ammonium chloride, tetradecyl dimethyl benzyl chloride Ammonium chloride or cetyl dimethyl benzyl ammonium chloride, the stabilizer is one or more of n-octanol, n-pentanol, n-h...

Embodiment 2

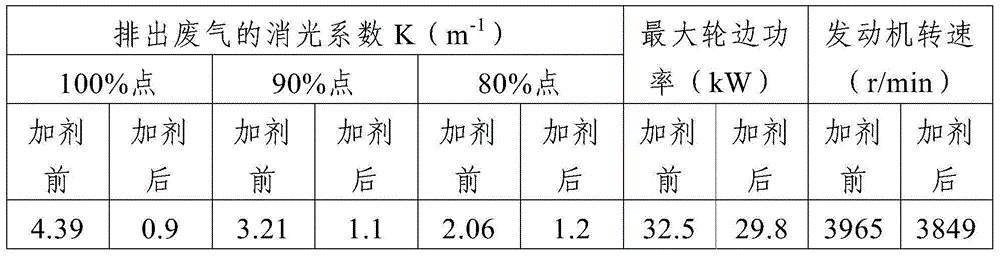

[0041] The present embodiment compression-ignition engine vehicle exhaust cleaning agent is made from the raw material of following mass percentage: ethanol 35%, polymethoxyl formal 1%, diethylene glycol alkyl ether 3%, stabilizing agent 10%, ten percent Hexane number improver 0.5%, power lubricant 3%, smoke clearing agent 3%, the balance is methanol, the power lubricant is a mixture of dimethyl carbonate, fatty acid methyl ester and fatty acid ethyl ester, the diethyl Glycol alkyl ether is one or more of diethylene glycol monohexyl ether, diethylene glycol dimethyl ether and diethylene glycol monooctyl ether, and the smoke clearing agent is barium petroleum sulfonate, cyclic One or more of barium alkanoate, iron naphthenate and quaternary ammonium salt, the quaternary ammonium salt is dodecyl dimethyl benzyl ammonium chloride, tetradecyl dimethyl benzyl chloride Ammonium chloride or cetyl dimethyl benzyl ammonium chloride, the stabilizer is one or more of n-octanol, n-pentano...

Embodiment 3

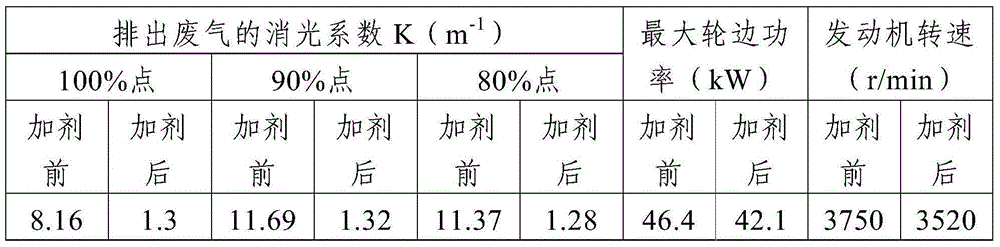

[0050] The present embodiment compression ignition type engine automobile tail gas cleaning agent is made by the raw material of following mass percentage: ethanol 20%, polymethoxyl formal 10%, diethylene glycol alkyl ether 2%, stabilizing agent 18%, ten percent Hexane number improver 2%, power lubricant 2%, smoke clearing agent 2%, the balance is methanol, the power lubricant is a mixture of dimethyl carbonate, fatty acid methyl ester and fatty acid ethyl ester, the diethyl Glycol alkyl ether is one or more of diethylene glycol monohexyl ether, diethylene glycol dimethyl ether and diethylene glycol monooctyl ether, and the smoke clearing agent is barium petroleum sulfonate, cyclic One or more of barium alkanoate, iron naphthenate and quaternary ammonium salt, the quaternary ammonium salt is dodecyl dimethyl benzyl ammonium chloride, tetradecyl dimethyl benzyl chloride Ammonium chloride or cetyl dimethyl benzyl ammonium chloride, the stabilizer is one or more of n-octanol, n-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com