Process for producing salinomycin by glucose supplement and fermentation based on metabolic parameter OUR (oxygen uptake rate)

A technology of salinomycin and sugar supplementation, which is applied in the field of salinomycin production based on metabolic parameter OUR sugar supplementation fermentation process, can solve the problems of increasing the cost of salinomycin fermentation, and achieve the weakening of glucose effect and the improvement of product titer. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Use media component 1

[0043] (1) Slant culture: Inoculate the Streptomyces albicans strain on a fresh slant and culture at 26°C for 8 days;

[0044] (2) Seed cultivation: insert the spores obtained in step (1) into the seed medium, and cultivate for 30 hours at 30°C and 260 r / min;

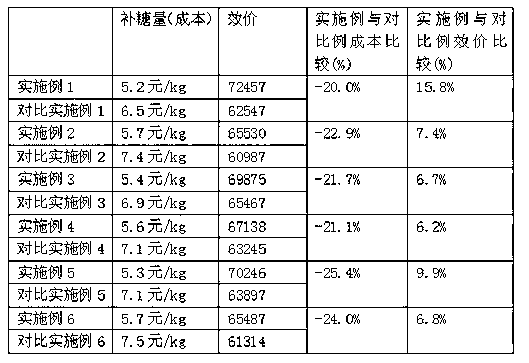

[0045] (3) Fermentation culture: Inoculate the seed solution obtained in step (2) into a fermenter (15L tank, about 8 liters of seed medium after sterilization), the inoculation amount is 10%, the culture temperature is 30-35°C, the pressure is 0.05MPa, DO Control it above 30%, and the speed is 250-500rpm. When OUR tends to be stable, start to add glucose with a mass percentage concentration of 60% at a flow rate of 10ml / h. After 280 hours of fermentation, it was put into a tank, and the potency was 72457u / ml, as shown in Table 1.

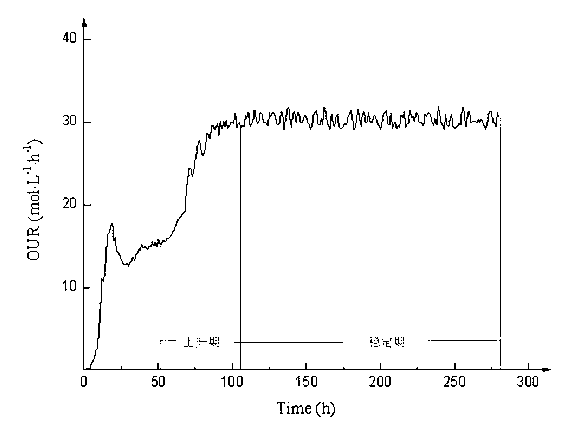

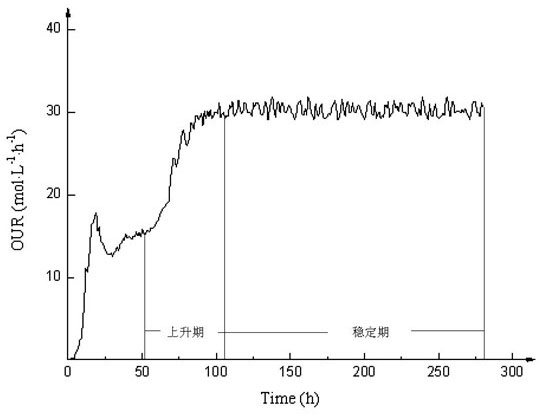

[0046] Such as figure 1As shown, 0-65h is the sugar-oil conversion period, and OUR rises; 65-110h, the sugar-oil conversion period ends, and OUR begins to r...

Embodiment 2

[0049] Use media component 1

[0050] (1) Slant culture: Inoculate the Streptomyces albicans strain on a fresh slant and culture at 30°C for 6 days;

[0051] (2) Seed cultivation: insert the spores obtained in step (1) into the seed medium, and cultivate for 30 hours at 35°C and 220 r / min;

[0052] (3) Fermentation culture: inoculate the seed liquid obtained in step (2) into a fermenter (30L tank, about 16 liters of seed medium after sterilization), the inoculum amount is 10%, the culture temperature is 30-35°C, the pressure is 0.05MPa, DO Control it above 30%, and the speed is 250-500rpm. When OUR tends to be stable, start to add sucrose with a mass percentage concentration of 40% at a flow rate of 25ml / h. After 300 hours of fermentation, put it into the tank. Titer 65530u / ml.

Embodiment 3

[0054] Use media component 2

[0055] (1) Slant culture: Inoculate the Streptomyces albicans strain on a fresh slant and culture at 28°C for 7 days;

[0056] (2) Seed cultivation: insert the spores obtained in step (1) into the seed medium, and cultivate for 30 hours at 32°C and 240 r / min;

[0057] (3) Fermentation culture: inoculate the seed solution obtained in step (2) into a fermenter (45L tank, about 24 liters of seed medium after sterilization), the inoculum amount is 10%, the culture temperature is 30-35°C, the pressure is 0.05MPa, DO Control it above 30%, and the speed is 250-500rpm. When OUR tends to be stable, start to add glucose with a mass percentage concentration of 50% at a flow rate of 30ml / h. Put the tank after 320 hours of fermentation. Titer 69875u / m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com