Ultra-large self-elevating wind turbine installation vessel with multi-type pile legs and design method thereof

A multi-type, installation ship technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of limiting the loading capacity and working water depth of super-large wind power installation ships, complicated construction technology, and high cost, and achieve the purpose of improving the hull Effects of stability, increased payload, and increased load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

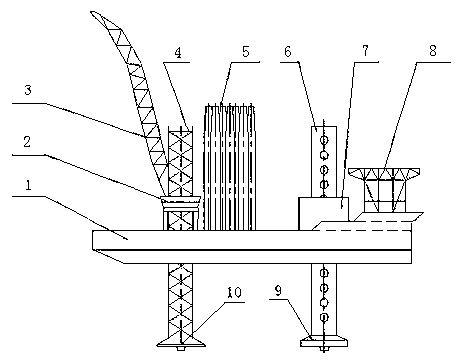

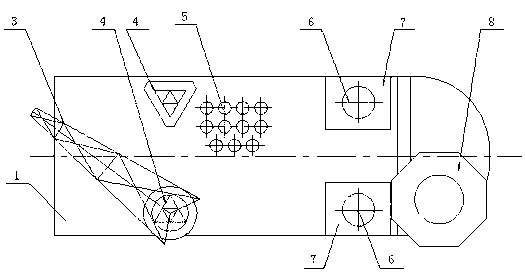

[0022] Such as figure 1 with figure 2 The present invention shows a specific implementation of the flip-type hoisting method of the helicopter platform, a super-large self-elevating wind power installation ship with multiple types of legs, including a hull 1, and the hull 1 is equipped with cargo 5 and a helicopter The platform 8, the hull 1 and the truss leg 4 are connected by a rack and pinion lifting system, the lower part of the truss leg 4 is fixedly connected with the truss leg shoe 10, and the truss leg 4 is equipped with a crane rotary table 2. The crane rotary table 2 is fixedly connected to the crane 3, the hull 1 and the shell-type l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com