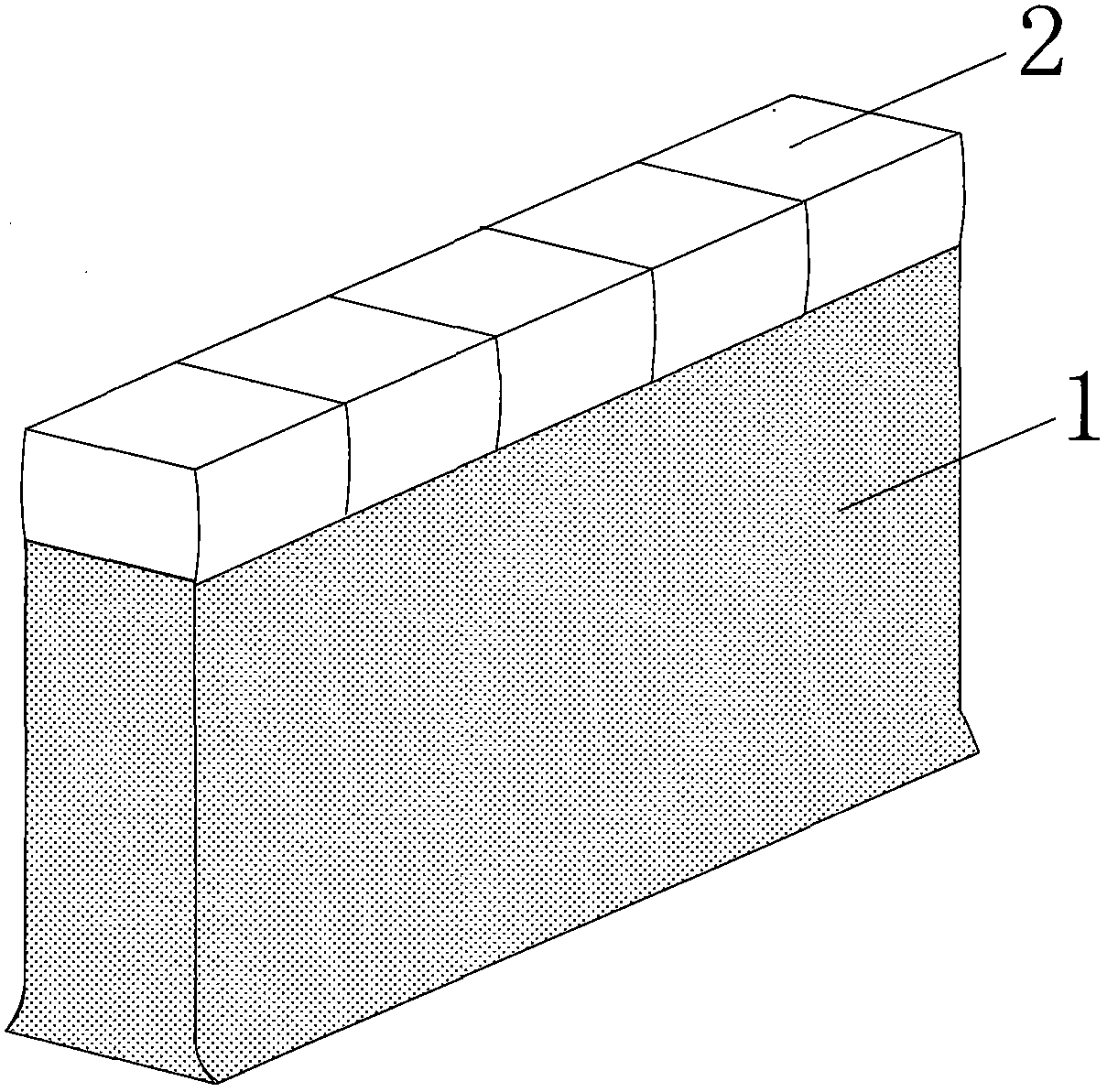

Roadside proper yielding unequal combined filling structure of gob-side entry retaining and construction method

An unequal and appropriate technology, applied in the field of filling technology, can solve the problems of high cost, complicated construction, and uncertain pressure, and achieve the effect of alleviating the impact without warning, convenient and easy construction, and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

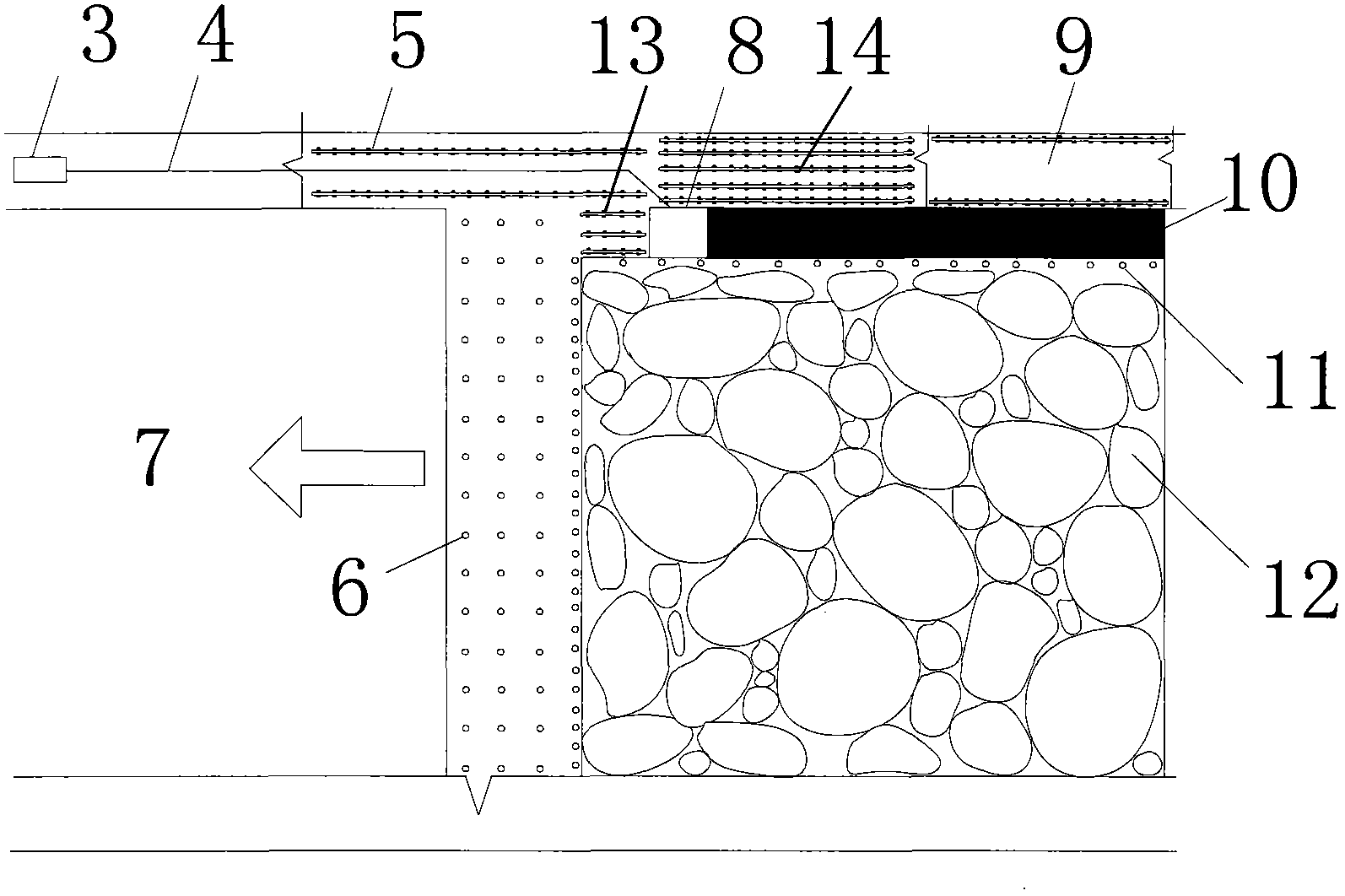

[0033] The structure and specific construction methods of the present invention will be described in detail below with reference to the accompanying drawings.

[0034] Step 1: After the excavation of the underground roadway, carry out anchor, cable, net, belt support and 6 supports of single hydraulic props on the working face, and arrange the working face at the same time. The goaf 12 is formed after the coal is coaled.

[0035] Step 2: Use a single hydraulic prop in the retaining entry 9 as the advance support 5 plus a hinged top beam support, and then use wooden pillars 11 for support and reinforcement within the filling width of the retaining entry side. With the advancement of the working face, the advance A single hydraulic prop is added to the support 5, and it is strengthened as a lag support 14; the lag support 14 and the wooden pillar 11 jointly bear the initial pressure of the roof before the upper filling body condenses.

[0036] Step 3: At the same time, the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com