Concrete pre-embedded pile for soft foundation reinforcement

A soft foundation and concrete technology, applied to sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of increasing the filling time of pre-embedded piles and reducing the work efficiency of technicians

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

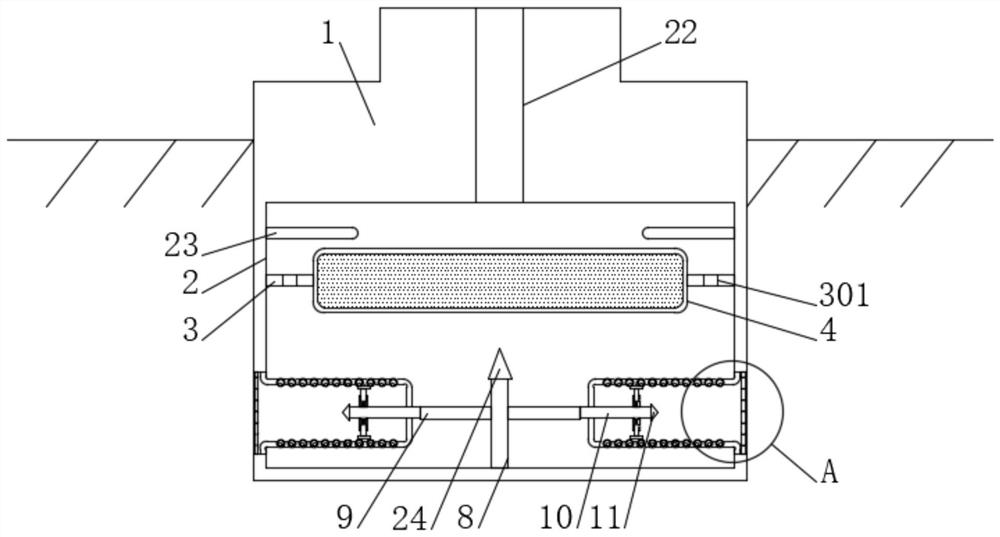

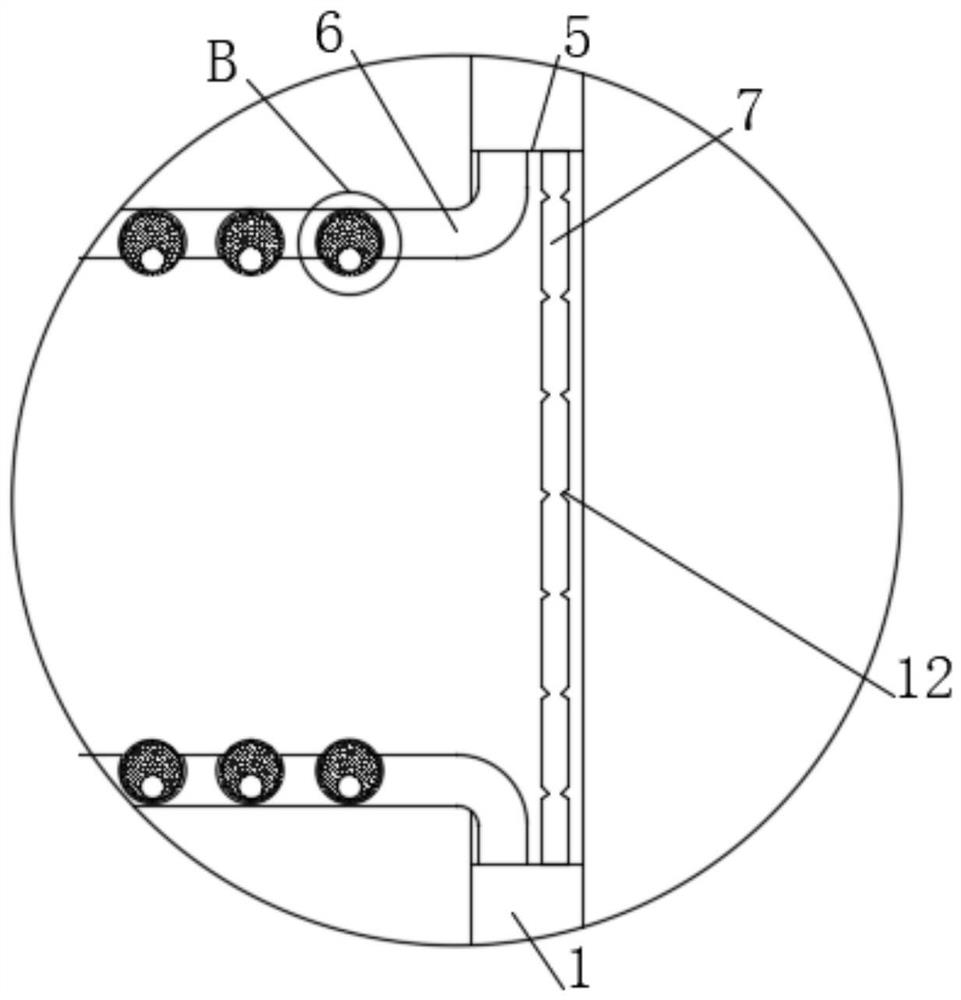

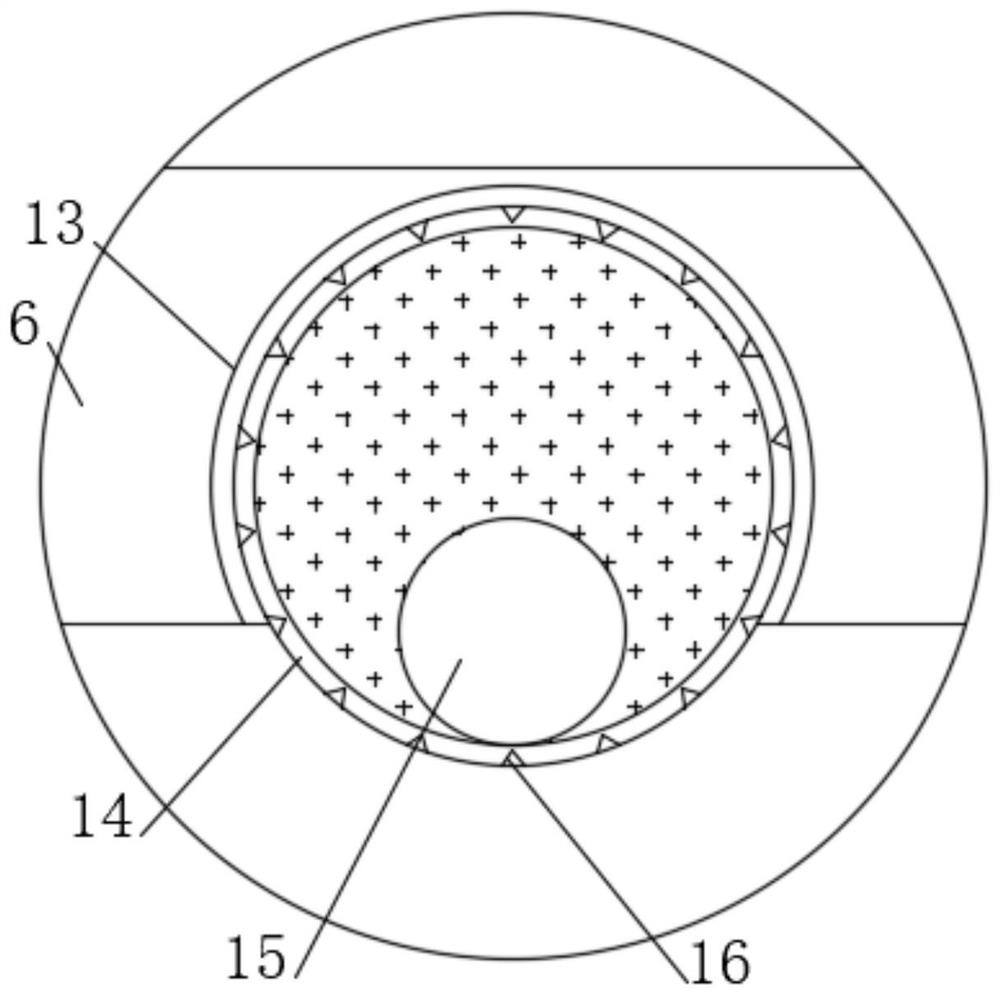

[0036] see Figure 1-3 , a concrete pre-embedded pile for soft ground reinforcement, comprising a pre-embedded pile 1, an embedded pile 1, a built-in cavity 2 dug inside the pre-buried pile 1, a connecting ring 3 fixedly connected to the inner wall of the built-in cavity 2, and a connecting ring The upper end of the ring 3 has a plurality of evenly distributed through holes 301, and the inner wall of the connecting ring 3 is fixedly connected with a cylindrical air bag 4 filled with ammonium bicarbonate powder, and a pair of strip holes are dug in the inner wall of the built-in cavity 2 5. The inner wall of the strip hole 5 is fixedly connected with a deformable rubber capsule 6 and a pre-sealed membrane 7. The deformed rubber capsule 6 is located in the built-in cavity 2, and the pre-sealed membrane 7 is located outside the deformed rubber capsule 6. The pre-sealed membrane 7 and the deformed rubber capsule 6 is filled with carbon dioxide gas, the inner bottom of the built-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com