Preparation method of Thiessen polygonal bionic artificial bone structure based on broken bone surface

A Tyson polygon, artificial bone technology, applied in the field of medical artificial bone, to achieve the effect of improving bonding strength, alleviating mechanical loosening and subsidence, and alleviating osteolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

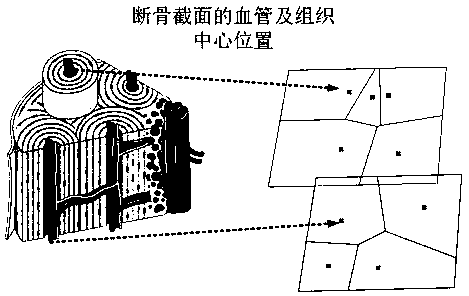

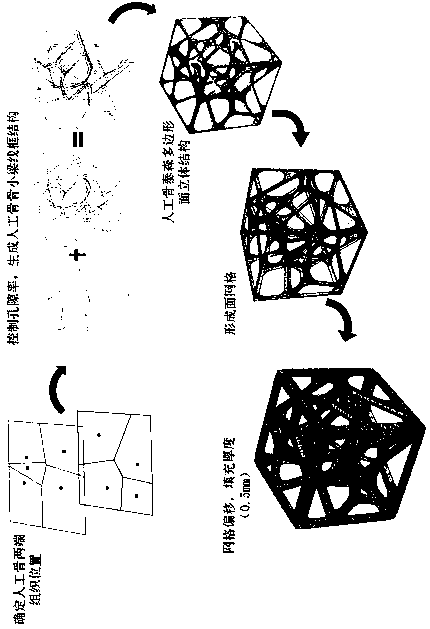

[0026] see Figure 1 to Figure 4 As shown, the preparation method of the Thiessen polygonal bionic artificial bone structure based on the fractured bone surface of the present invention is applicable to the structural design of the artificial bone implant with high connectivity gradient, comprising the following steps:

[0027] Step (1) Carry out computer tomography scanning or take pictures with a high-resolution camera to obtain a grayscale image of the broken bone section of the patient, extract the coordinates of the center point of the bone tissue, obtain the positions of blood vessels and tissues at both ends of the broken bone section, and derive the three-dimensional coordinates of the center of the tissue ;

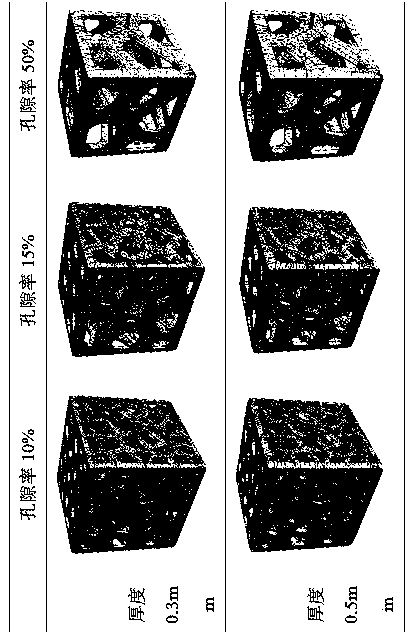

[0028] Step (2) According to the three-dimensional coordinate position of the tissue center of the broken bone section, design the artificial bone implant so that the section of the artificial bone is the same as that of the autologous bone. Under the condition o...

Embodiment

[0033] see Figure 1 to Figure 4 As shown, the bionic artificial bone structure based on the fractured bone surface of the present invention is consistent with the human's own bone modulus, which is beneficial to the bionic processing of the bone implant structure, and replicates the characteristics of natural bone at all levels (such as microstructure, machinery, mass transport and biological properties), and has excellent cell penetration, nutrient diffusion and osteoconduction properties. The mechanical and fluid properties of the Thiessen polygonal artificial bone scaffold structure depend on the microscopic porous structure, the total porosity, which also depends on the microscopic bone index (trabecular thickness, trabecular gap and trabecular number), all of these indicators in the structure of the present invention are controllable during the design process. And the design based on the broken bone surface provides favorable growth conditions for the growth of bone tis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com