Patents

Literature

178 results about "Bone trabeculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A trabecula generally has a mechanical function, and is usually composed of dense collagenous tissue (such as the trabecula of the spleen). They can be composed of other materials such as muscle and bone. In the heart, muscles form trabeculae carneae and septomarginal trabecula. Cancellous bone is formed from groupings of trabeculated bone tissue.

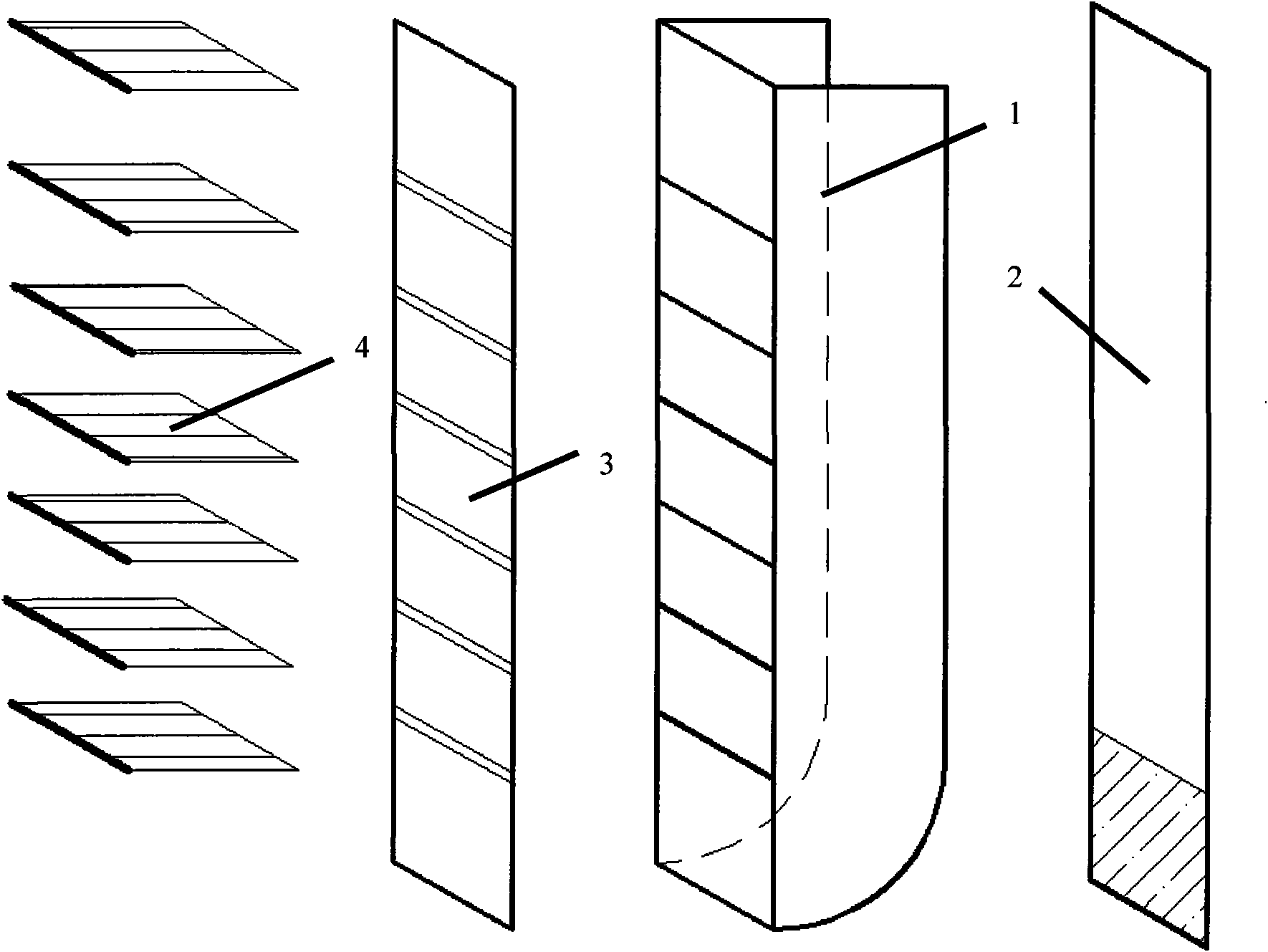

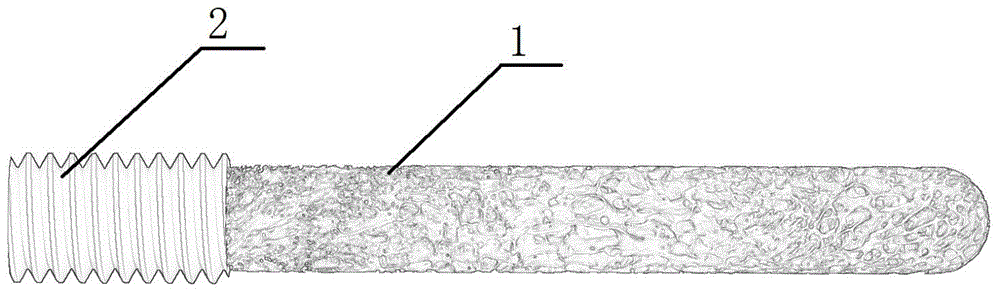

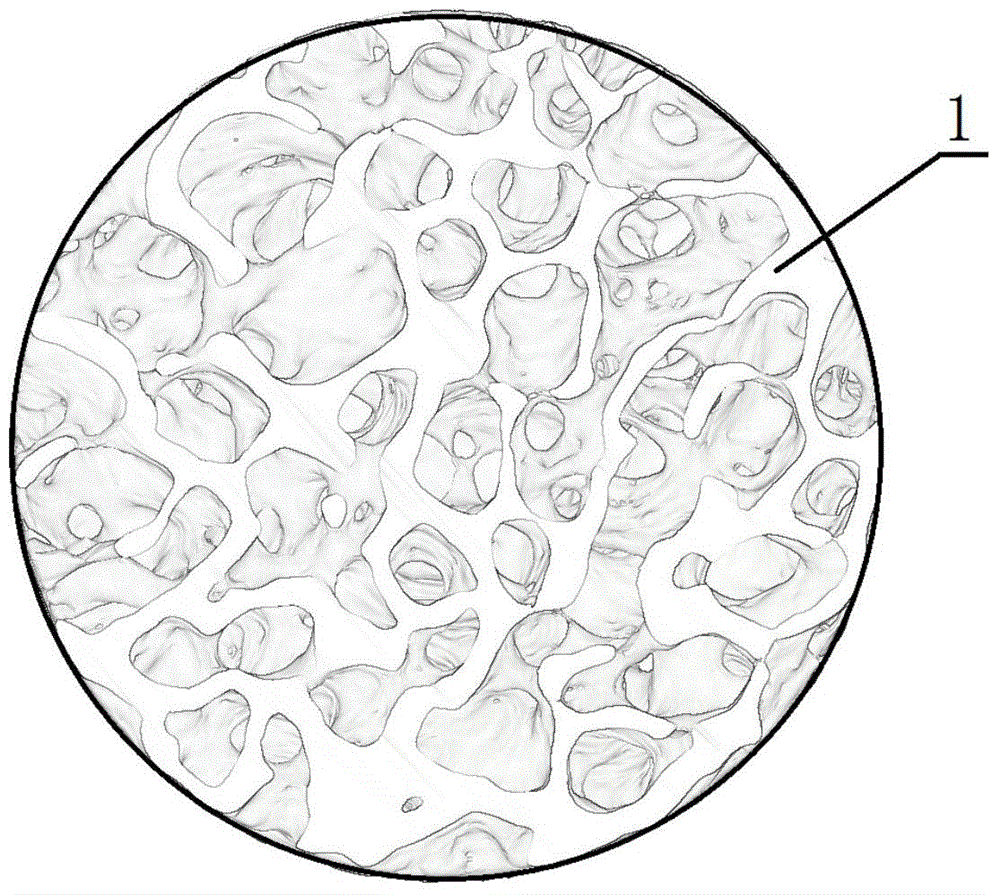

High-strength small-bore metal bone trabecula and preparation method of same

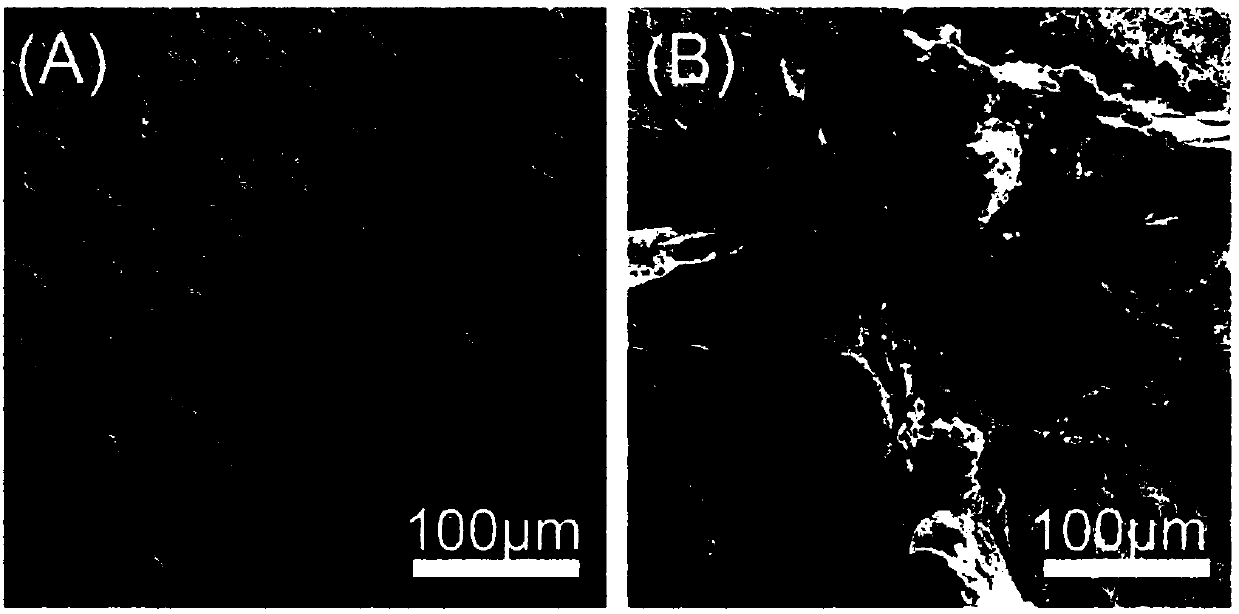

InactiveCN104887351AHigh strengthImprove uniformityAdditive manufacturing apparatusBone implantStructure of the EarthHigh intensity

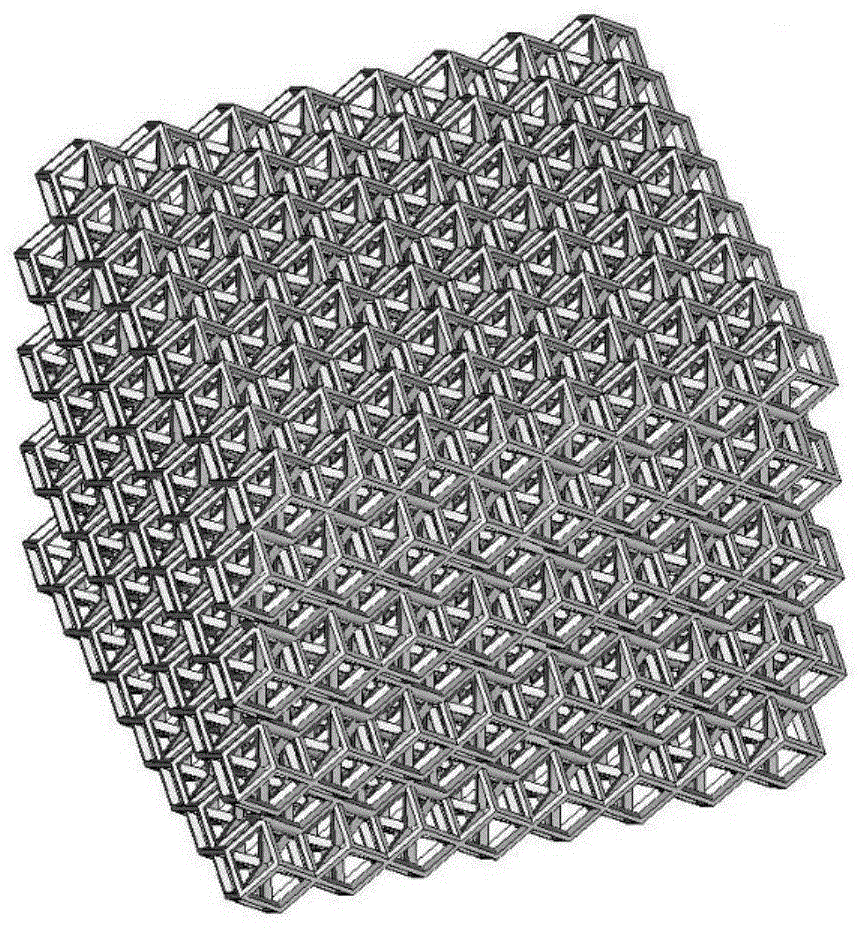

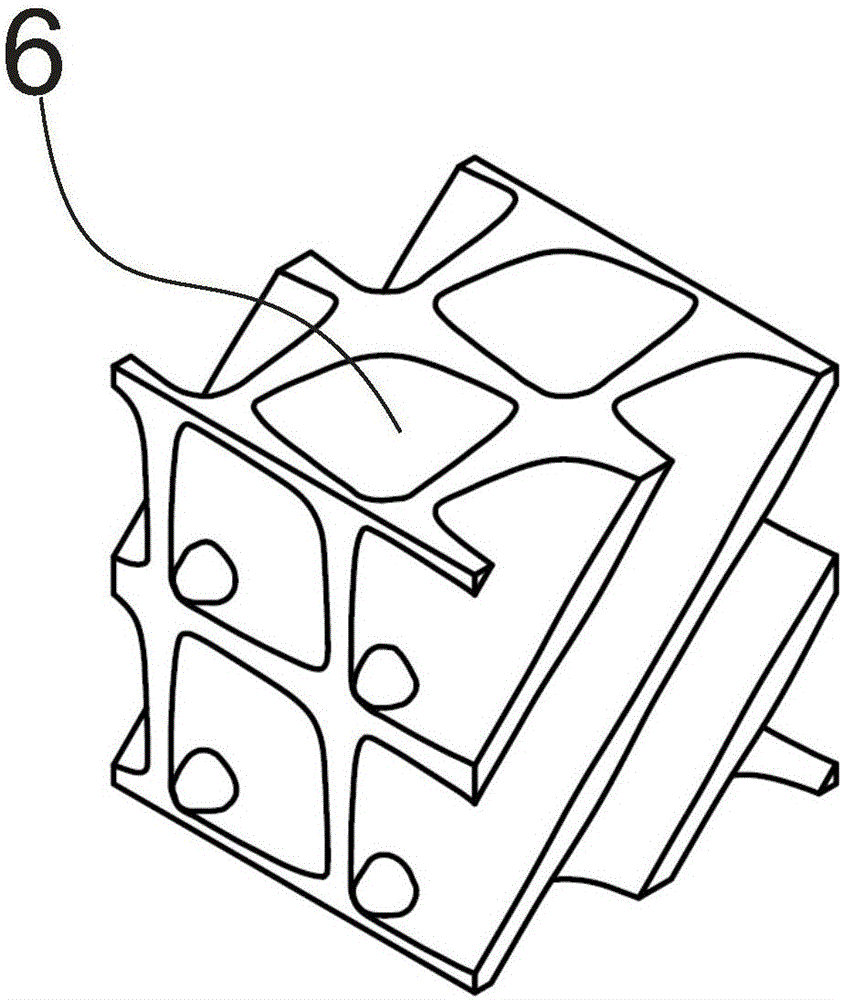

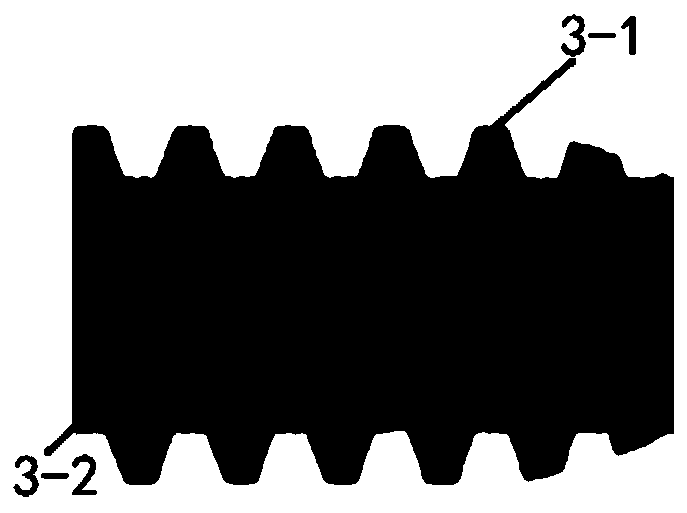

The invention provides a high-strength small-bore metal bone trabecula and a preparation method of the same. The high-strength small-bore metal bone trabecula is made through overlapping of a plurality of basic units, wherein the basic unit has seamed edges and is solid, other parts have a hollow polyhedral structure, one face of one basic unit coincides with one face of an adjacent basic unit, and reinforced bars are disposed inside the basic unit. The invention also provides a method to prepare the metal bone trabecula, which comprises the steps: 1. modeling is completed; 2. sectioning is completed; 3. a base plate is pre-heated; 4. powder is pre-heated; 5. areas are selected for melting and scanning; 6. the fourth and the fifth steps are repeated to obtain a 3D printing part; 7. residual powder is removed; and 8. electrochemical corrosion is carried out to obtain the high-strength small-bore metal bone trabecula. The high-strength small-bore metal bone trabecula provided by the invention has compression strength of 60 MPa-90 MPa, and effective aperture of 100 mum-150 mum, wherein the aperture is reduced by over 50% and the compression strength increases by over 20% in comparison with those of a conventional 3D printing porous material. The high-strength small-bore metal bone trabecula provided by the invention is more beneficial for bone in-growth and cell growth.

Owner:西安赛隆增材技术股份有限公司

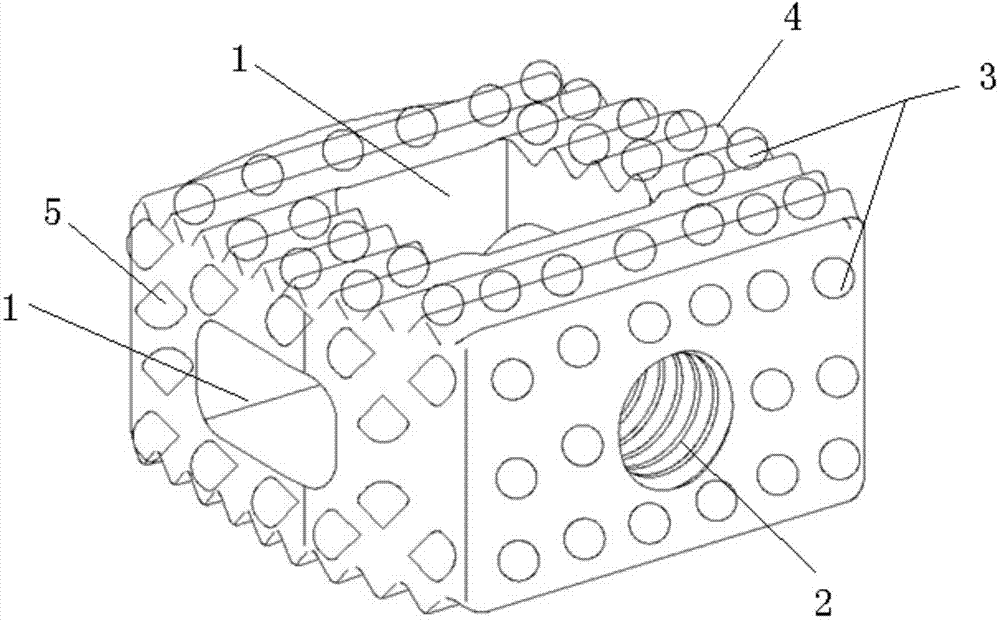

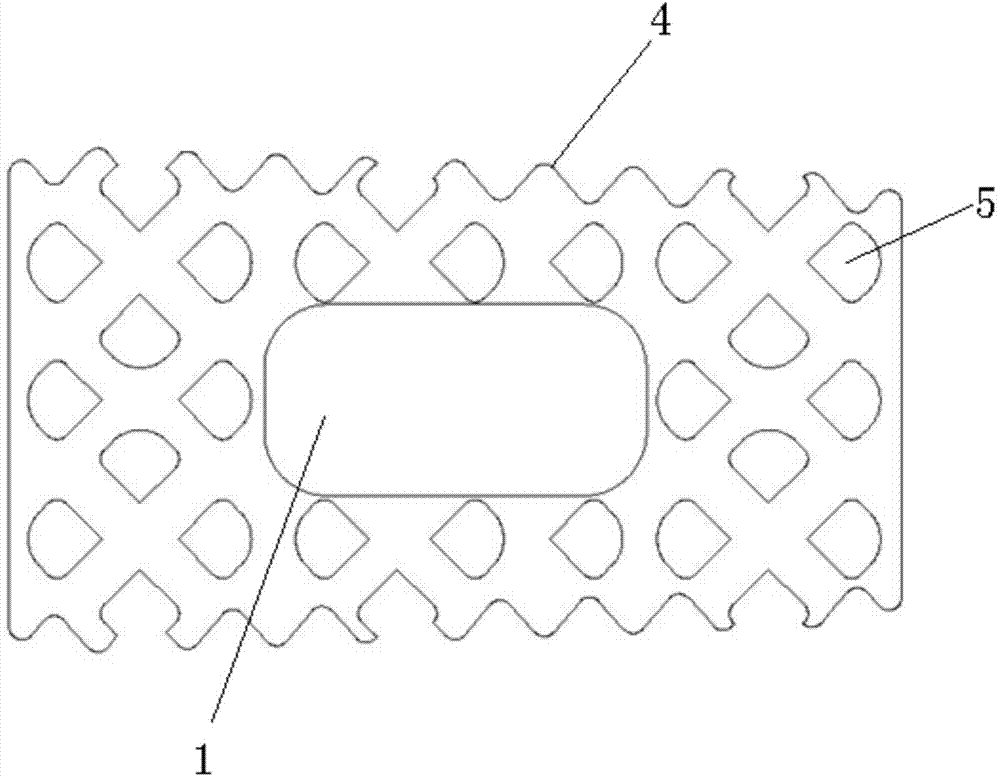

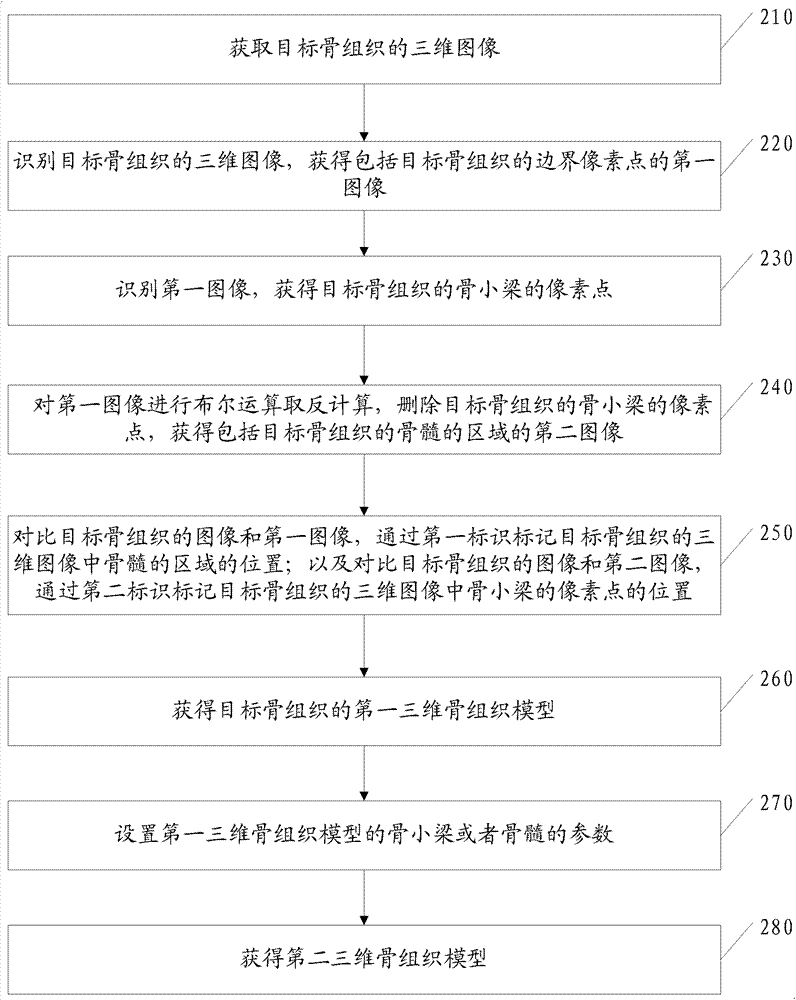

Bionic bone trabecula cervical vertebral fusion cage and manufacturing method thereof

InactiveCN104706446AImprove fusion rateGood medical recovery effectSpinal implantsHuman bodyCancellous bone

The invention discloses a bionic bone trabecula cervical vertebral fusion cage. The bionic bone trabecula cervical vertebral fusion cage is characterized in that a body of the cervical vertebral fusion cage is in the shape of a hexagonal prism, the interior of the body is in the shape of a three-dimensional net, and square through holes (1) are formed in the middles of the upper end face, the lower end face, the front end face and the rear end face of the body respectively. A manufacturing method of the bionic bone trabecula cervical vertebral fusion cage comprises the following steps that 1, original parameters of the bone trabecula are calculated; 2, a target model is established; 3, specific hole unit bodies are stacked within the boundary range of the target model disorderly, the sizes of the hole unit bodies, the distance between hole units, the sizes of ribs in the hole unit bodies, the sizes of connecting ribs between the hole unit bodies and the precision and appearance precision of an integrated bone trabecula structure are set, and finally the original target model is deleted, and the bone trabecula structure obtained after filling is reserved. According to the bionic bone trabecula cervical vertebral fusion cage and the manufacturing method of the bionic bone trabecula cervical vertebral fusion cage, a cancellous bone structure of a human body is simulated in the microstructure aspect through a 3D printing product, and the technical problems that according to a traditional centrum fusion cage, only the mechanical supporting function is achieved, and a formed bone can not be induced to grow are solved.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

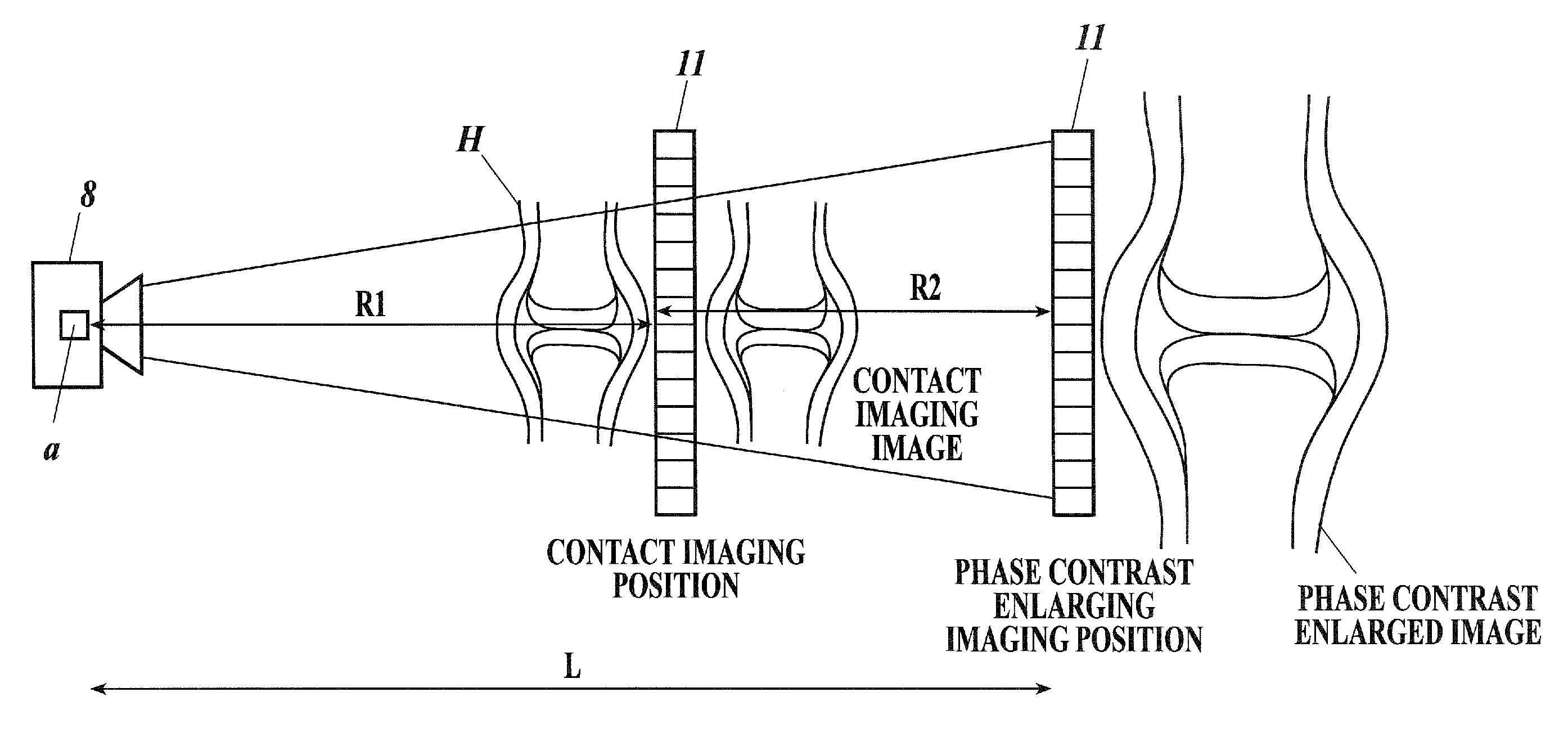

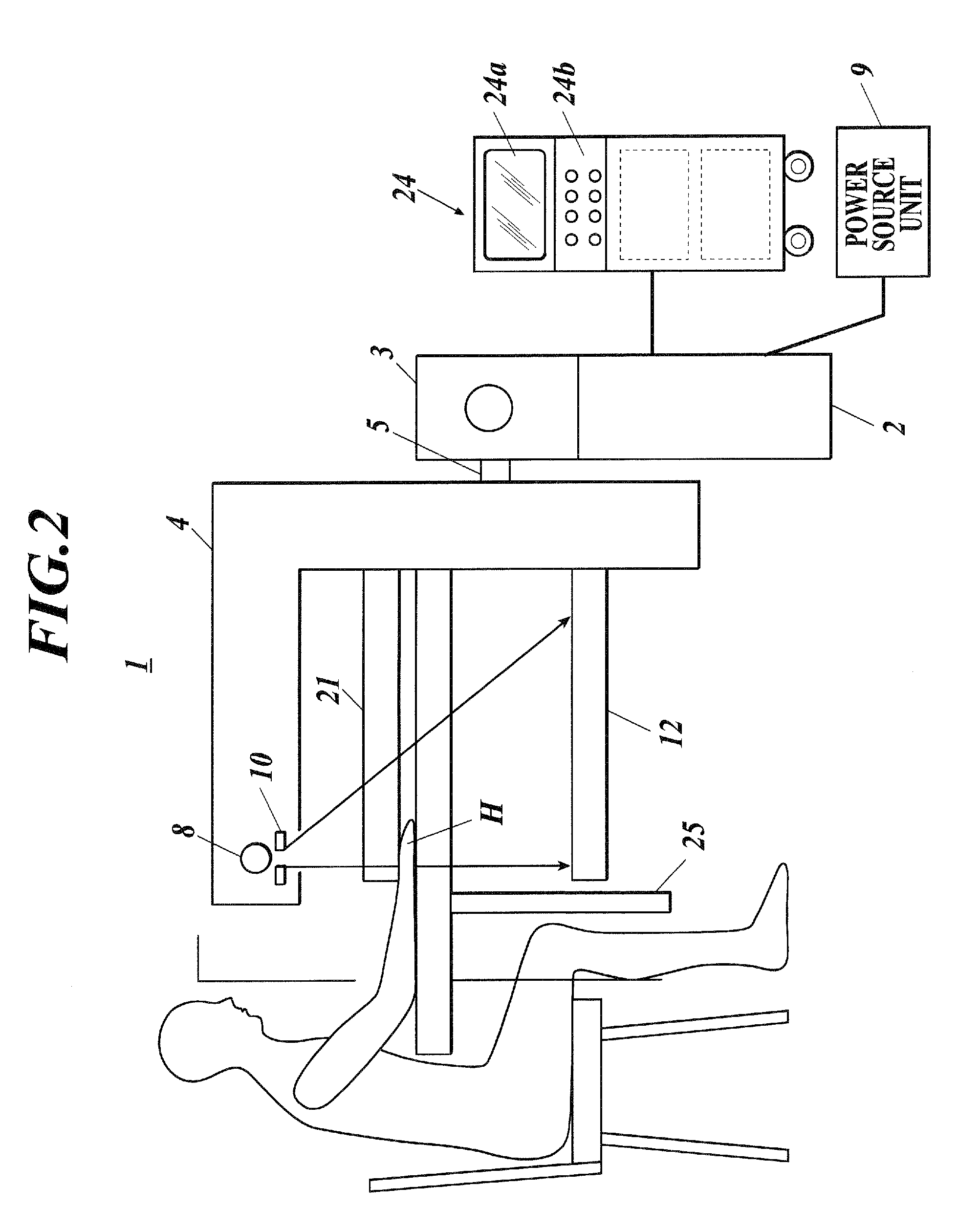

X-ray image analyzing system and program

An X-ray image analyzing system, including:an X-ray source for radiating an X-ray; an X-ray detector for detecting an X-ray image radiated onto an x-ray image detection surface, wherein phase contrast X-ray simple imaging is capable of being performed determining a trabecular bone index computing region, computing a trabecular bone index indicating a state of a trabecula from image data in the trabecular bone index computing region, determining a bone-flesh boundary index computing region by a second region determination method different from the first region determination method, and computing a bone-flesh boundary index indicating smoothness of a bone-flesh boundary from image data in the bone-flesh boundary index computing region.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

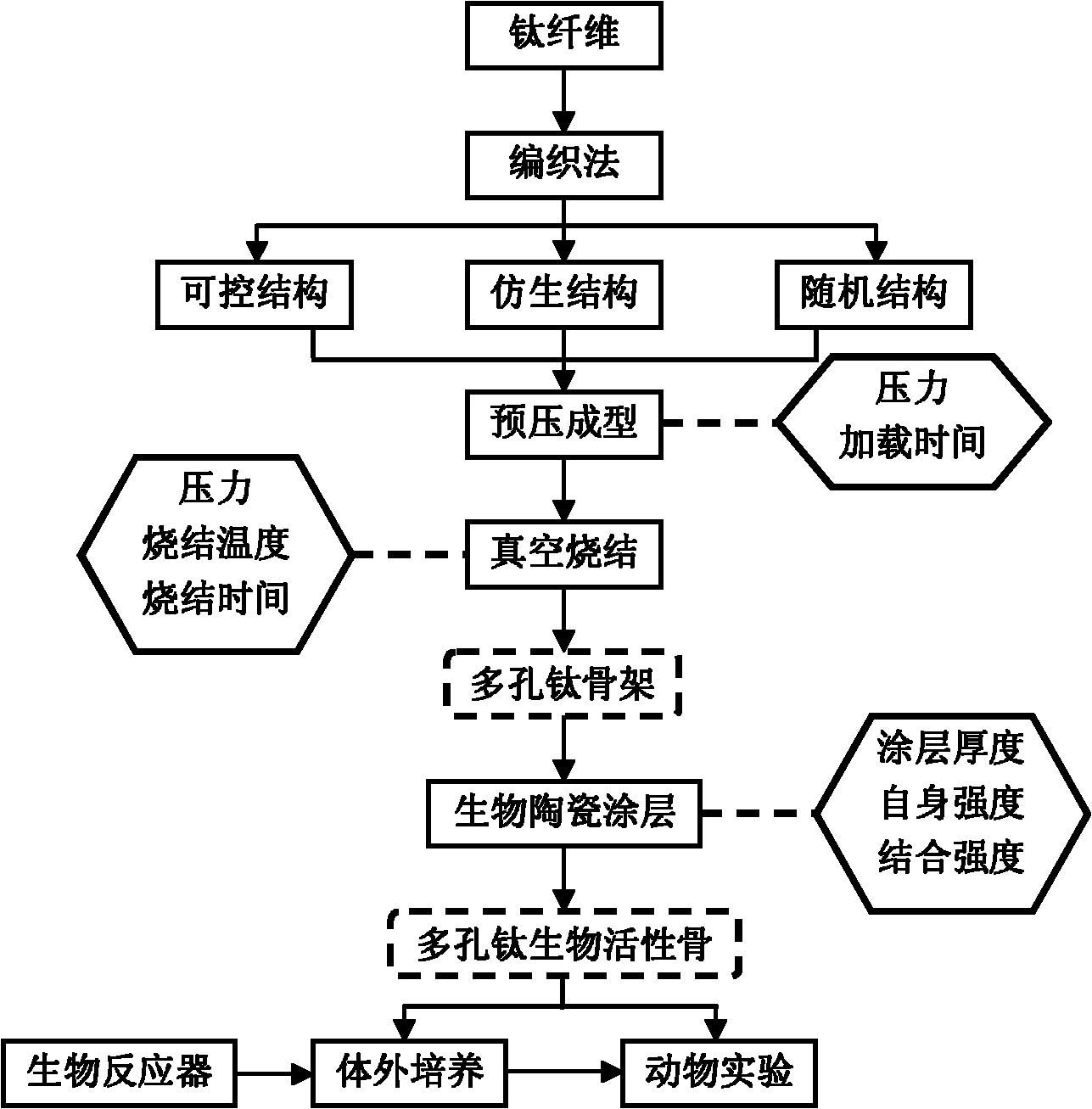

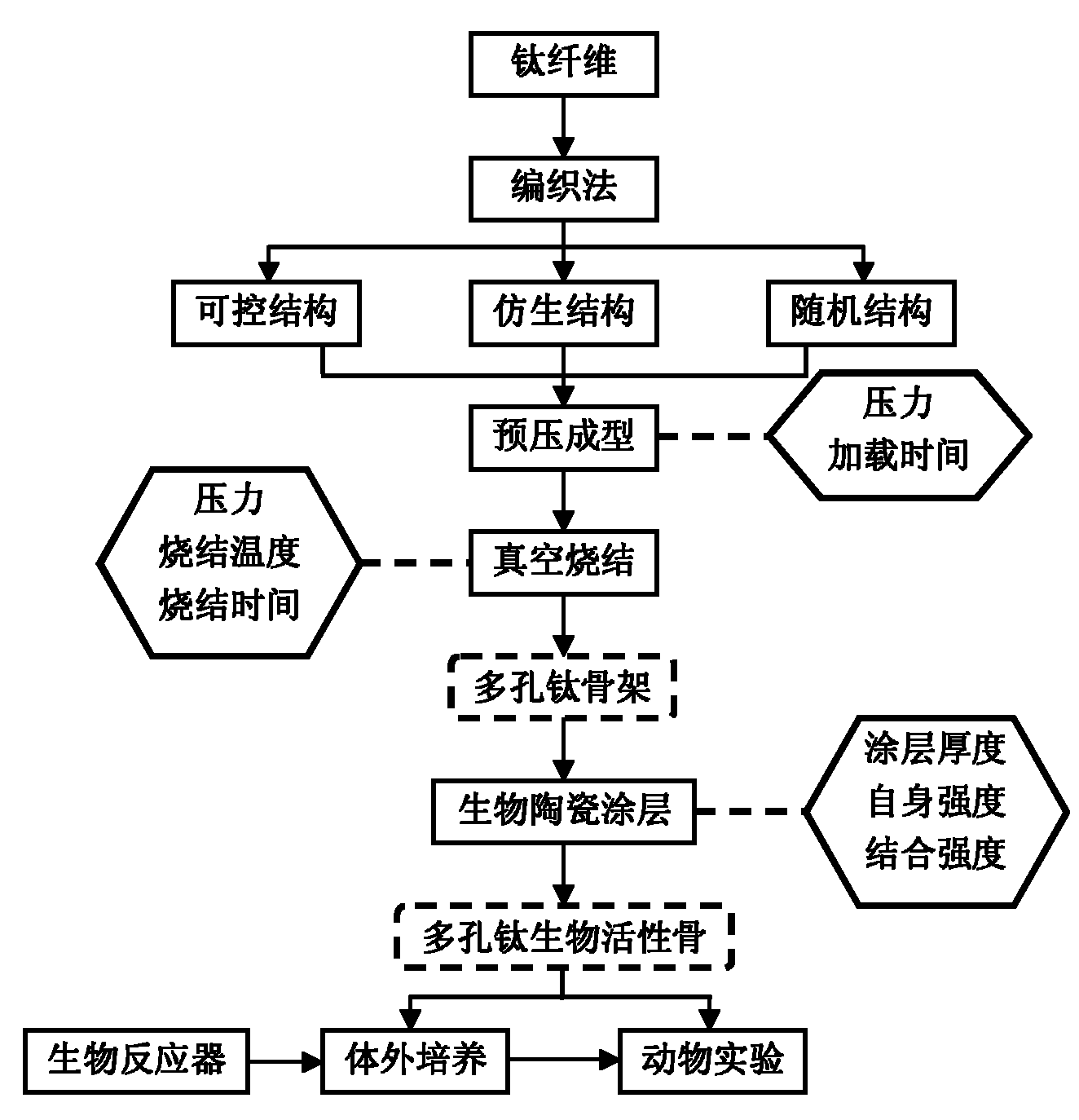

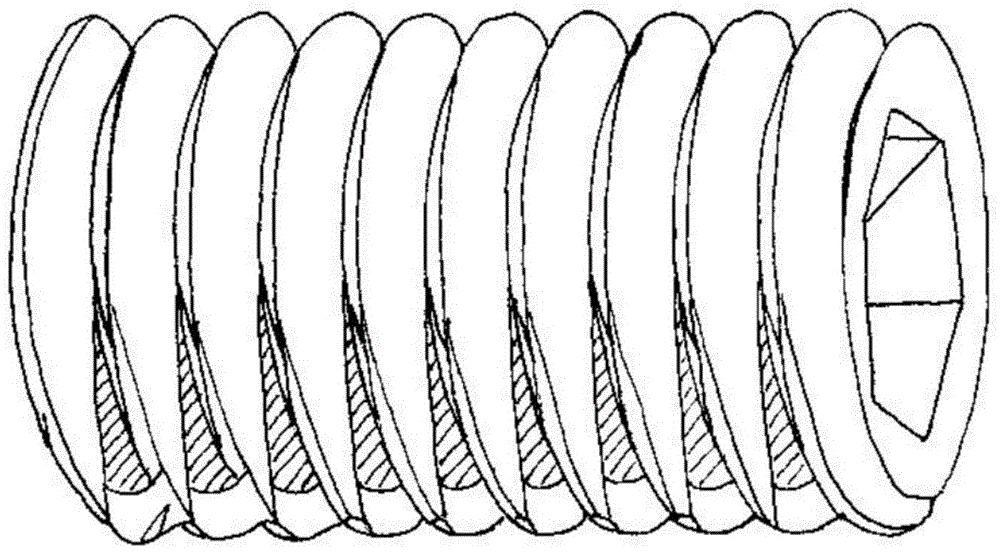

Preparation method of bio-ceramic coating titanium-wire sintering porous titanium artificial bone

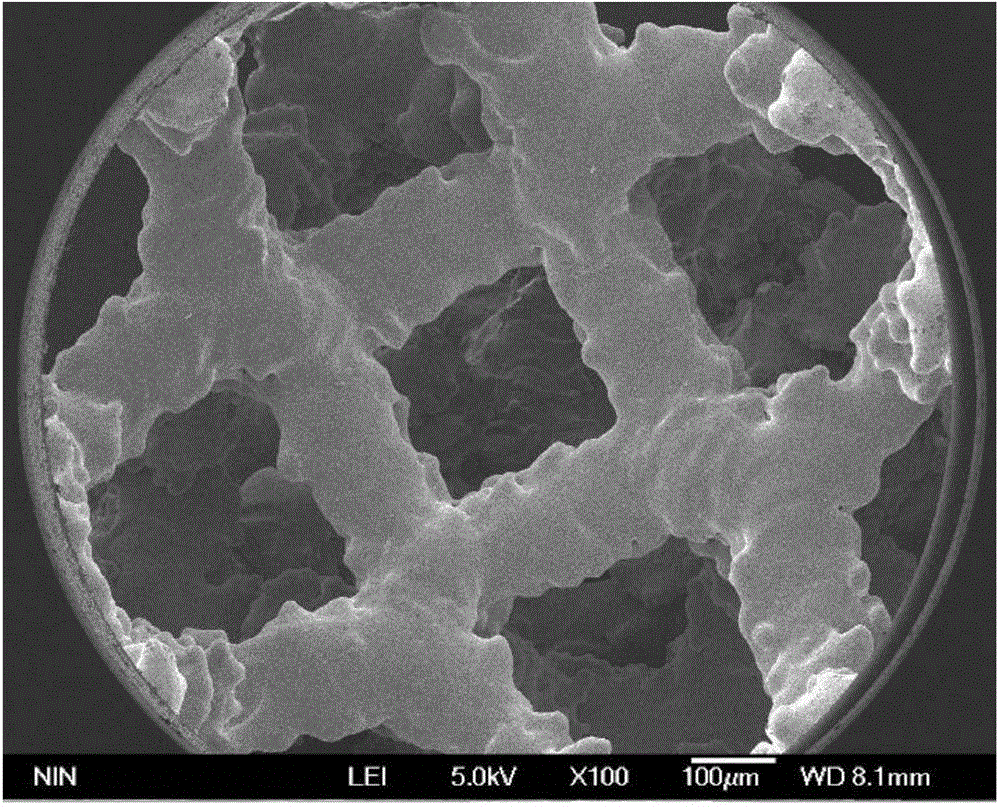

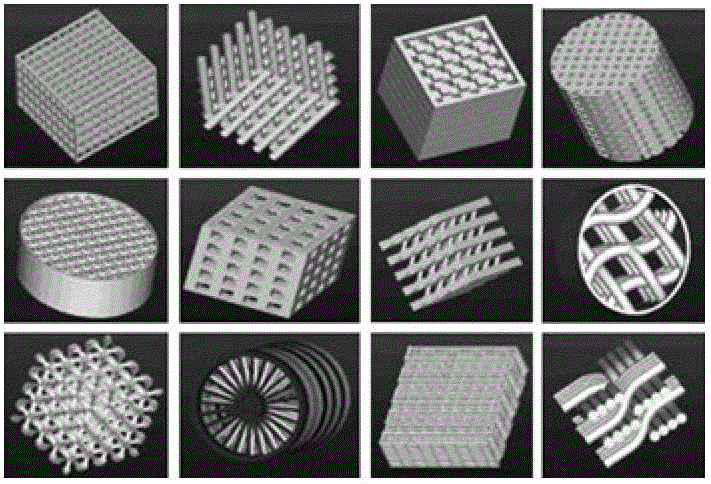

InactiveCN101889912AHave biological propertiesBiologically activeBone implantCoatingsFiberPrincipal stress

The invention discloses a preparation method of a bio-ceramic coating titanium-wire sintering porous titanium artificial bone, belonging to the biomedical engineering field. In the invention, a three-dimensional weaving method is utilized, a titanium metal fiber wire is constructed into a controllable structure model, a random structure model and a bionic structure model which can stimulate the bone trabecula and principal stress line of a human bone, and then is prepared into the porous titanium artificial bone through prepressing molding and vacuum sintering, after that, a sol-gel method is utilized to manufacture a gradient coating or a complex coating on the surface of the porous titanium artificial bone, so that the gradient coating transiting from titanium dioxide to bio-ceramics or the bio-ceramics-titanium dioxide complex coating is formed on the surface of the porous titanium artificial bone to obtain the bio-ceramic coating titanium-wire sintering porous titanium artificial bone. The preparation method not only can protect the titanium metal skeleton and prevent titanium ions from dissociating to enter a human body, but also can ensure that the titanium metal skeleton the surface of which is coated with the bio-ceramics has the biological characteristics, therefore, the bio-ceramic coating titanium-wire sintering porous titanium artificial bone can be applied to repairing clinical segmental defect of long bones.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method and use of medical metal artificial bone trabecula

ActiveCN101416906AIncrease the surface friction coefficientStable structureBone implantHigh surfaceBone remodeling

The invention discloses a metal artificial bone trabecula for medical purposes. The structural design of the metal artificial bone trabecula is completed by a computer, and then inputted in an electron beam fusion former; the high temperature generated by electron beams is used to carry out the stratified scanning and high-temperature fusion to titanium alloy powder in the former so as to obtain the metal artificial bone trabecula with bio-cancellous bone morphology, strength and elasticity modulus and a rough and loose outer surface formed by a porous structure. The obtained artificial bone trabecula has mechanical and biological characteristics similar to a human bone, high surface friction coefficient, stable structure and wide range of application, and is applicable to various bone defects, bone filling, bone supporting, bone remodeling and bone repair in a human skeletal system as well as bone restoration of bone remodeling and substitute bone of different bone joints of a human body.

Owner:TIANXINFU (BEIJING) MEDICAL APPLIANCE CO LTD

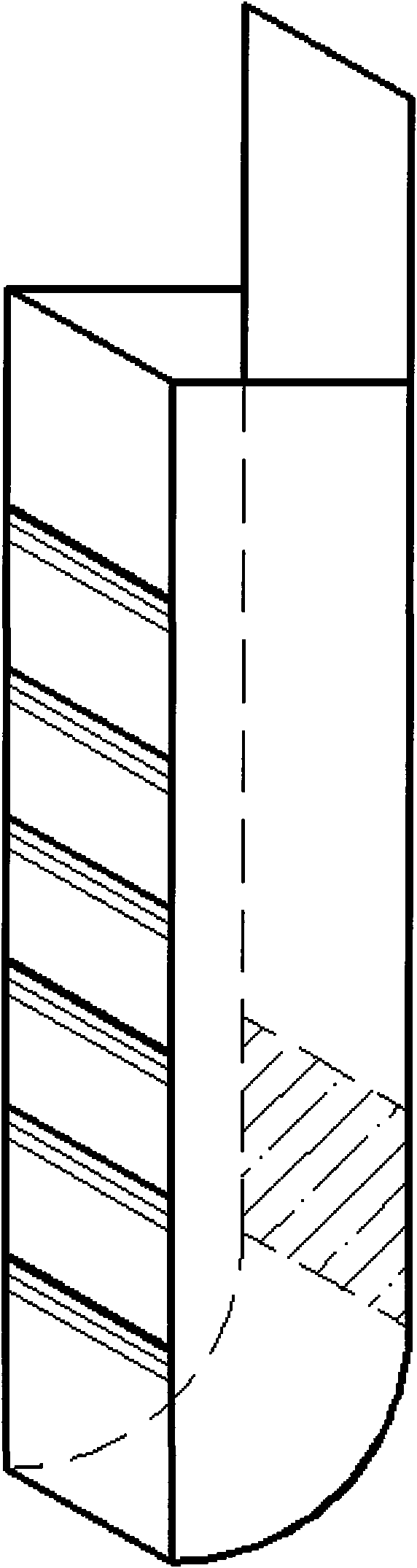

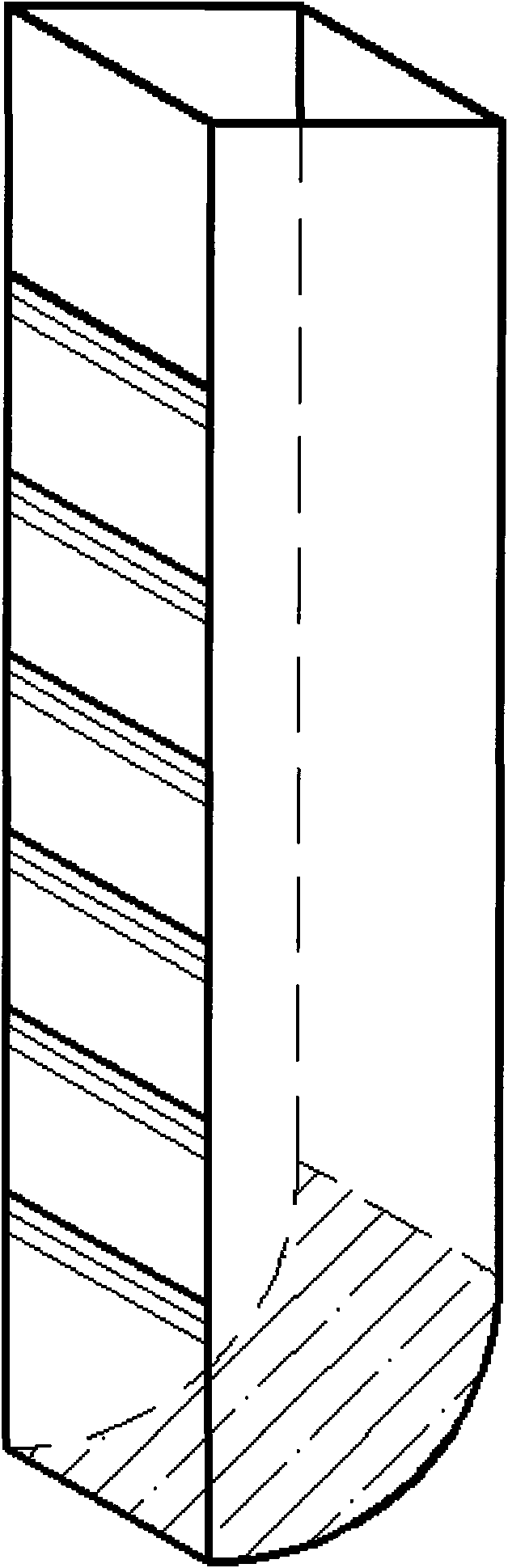

Press-in type slide-vane sampler for acquiring soft mud sample and sampling method

The invention provides a press-in slide-vane sampler structure for acquiring a soft soil, sludge or sewage sludge undisturbed sample with high water content in a sludge storage field, dredger fill field and landfill field and an installation and using method. The press-in slide-vane sampler structure can sample according to the conditions of soft flow state soil in the depth direction of sludge storage yards and dredge fill fields, and the acquired mud sample retains in-situ physical and chemical properties in the sampler. The whole structure comprises a three-sided square cylinder, a slide soft vane, a trabecula slot baffle plate and a trabecula. The sampler adopts a modular design, can control the length of sample separation length as well as the size of a sampling region and sampling precision. The sampler is simple, light, simple and convenient in operation, high in efficiency and low in sampling cost.

Owner:HOHAI UNIV

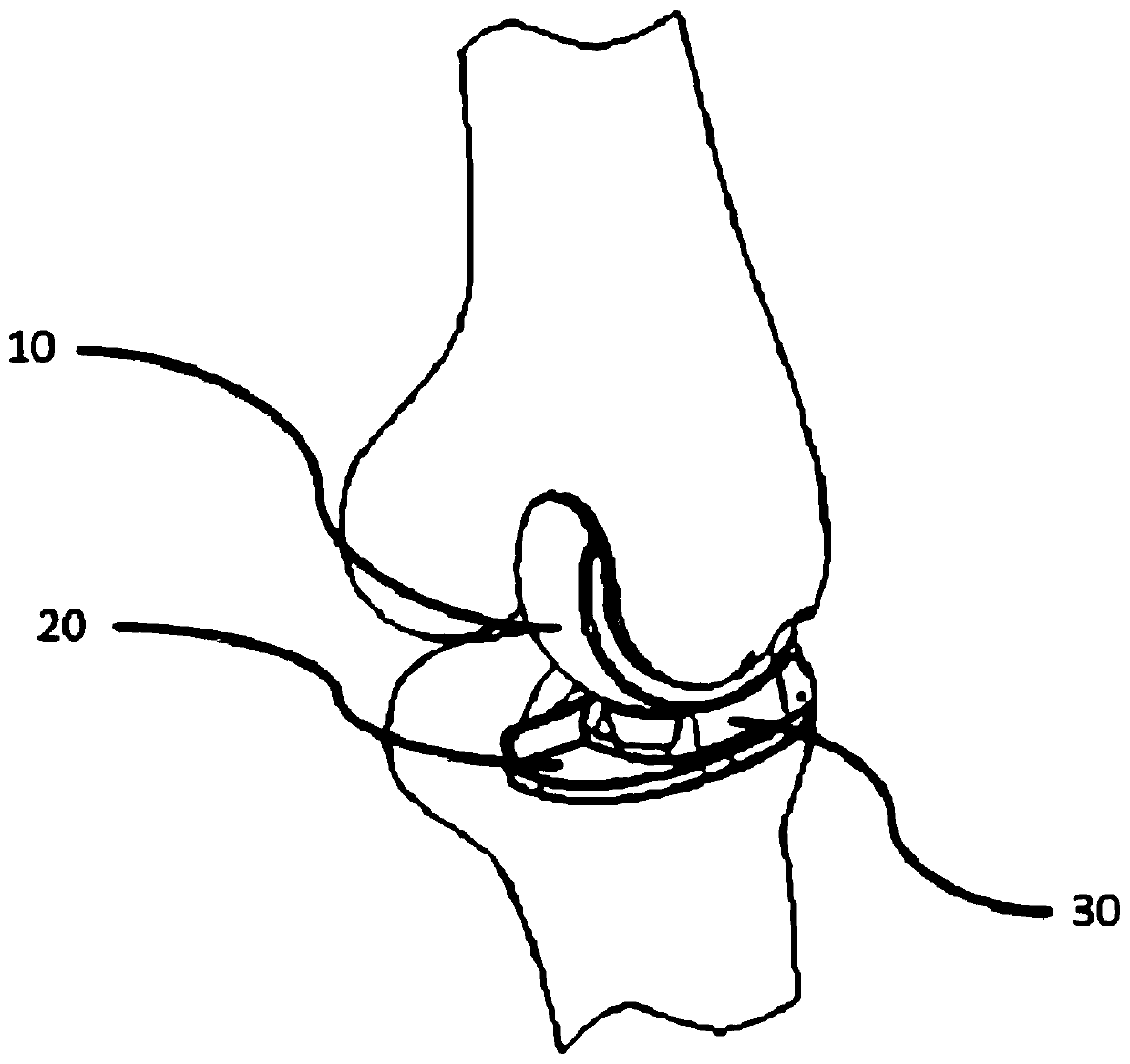

Bone induction differentiated metal bone trabecula knee joint prosthesis and preparation method thereof

The invention belongs to the field of medical apparatus, and particularly relates to a bone induction differentiated metal bone trabecula knee joint prosthesis and a preparation method thereof under the precision control using incremental manufacturing technology. The prosthesis comprises a femoral condyle prosthesis, a tibial plateau prosthesis, a tibial plateau pad prosthesis and a patellar prosthesis. Osseointegration interfaces of the femoral condyle prosthesis, tibial plateau prosthesis and patellar prosthesis is in the structure of the bone induction differentiated metal bone trabecula. The preparation method comprises the steps of determining the gradient structure of stress and strain in knee prosthesis, determining the parameters of the porous structure of trabecular bone, establishing a three-dimensional model of the porous structure, conducting slicing and stratification treatment of the three-dimensional model, and conducting electron beam incremental manufacturing of the knee joint prosthesis metal bone trabecula, cooling to obtain the final finished product. The bone induction differentiated metal bone trabecula knee joint prosthesis and the preparation method thereof for the first time achieve the balance between the stress and bone induction performance for stress regions of different osseointegration interfaces of bone in knee joint, satisfy the differentiation requirement of bone induction, provide a preparation method of mass production, and effectively reduces manufacturing cost.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

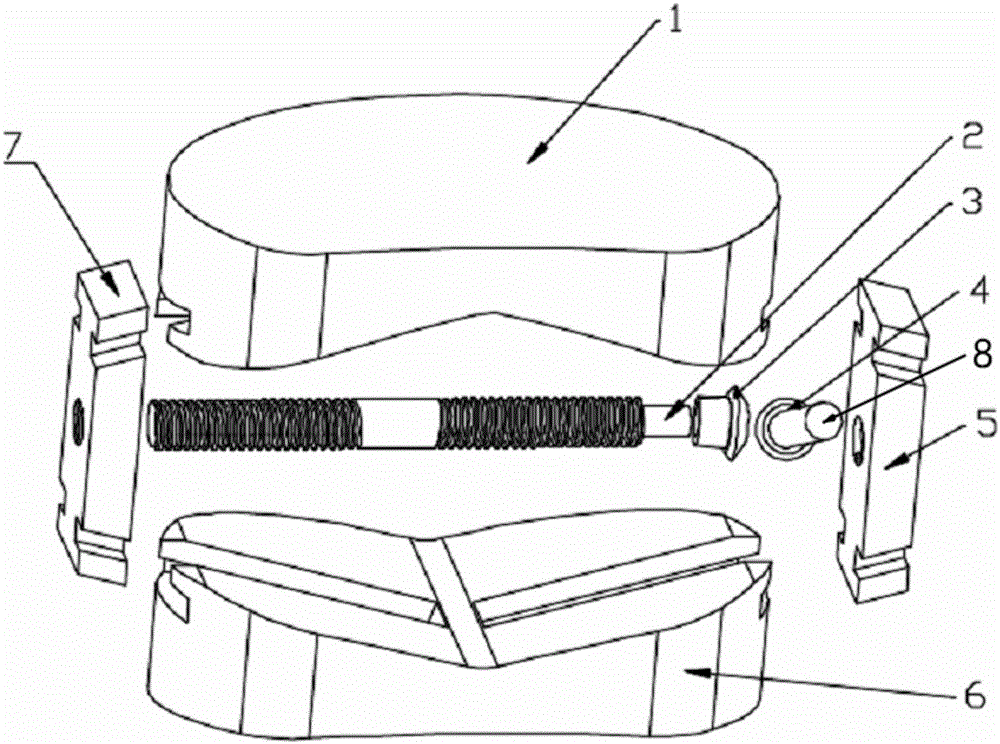

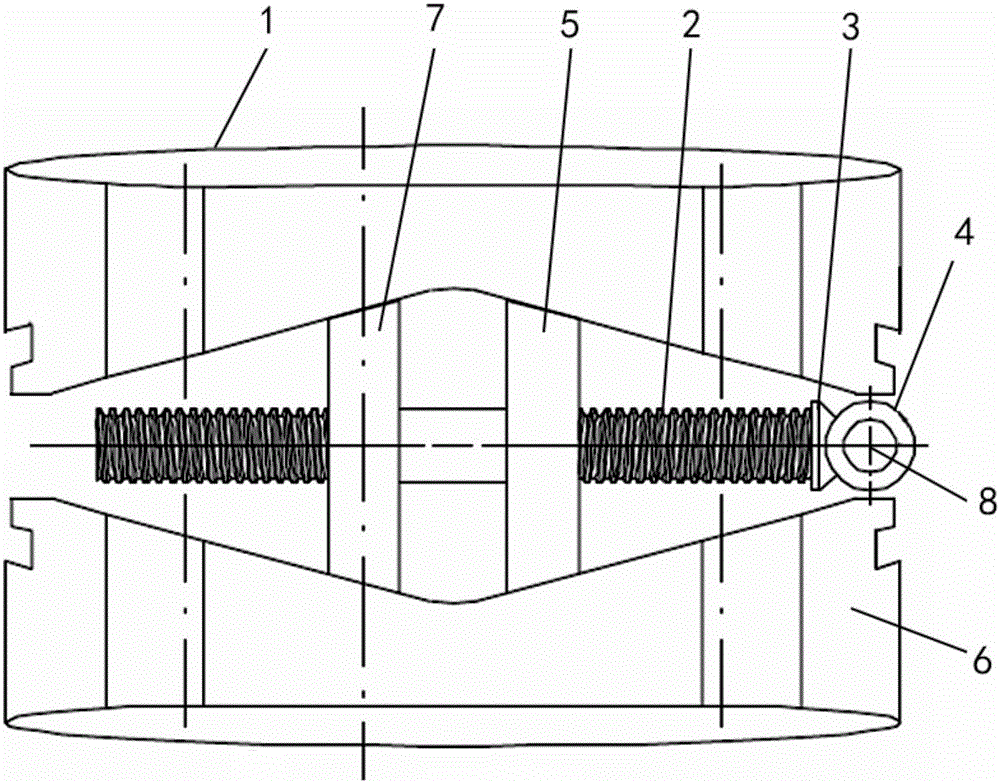

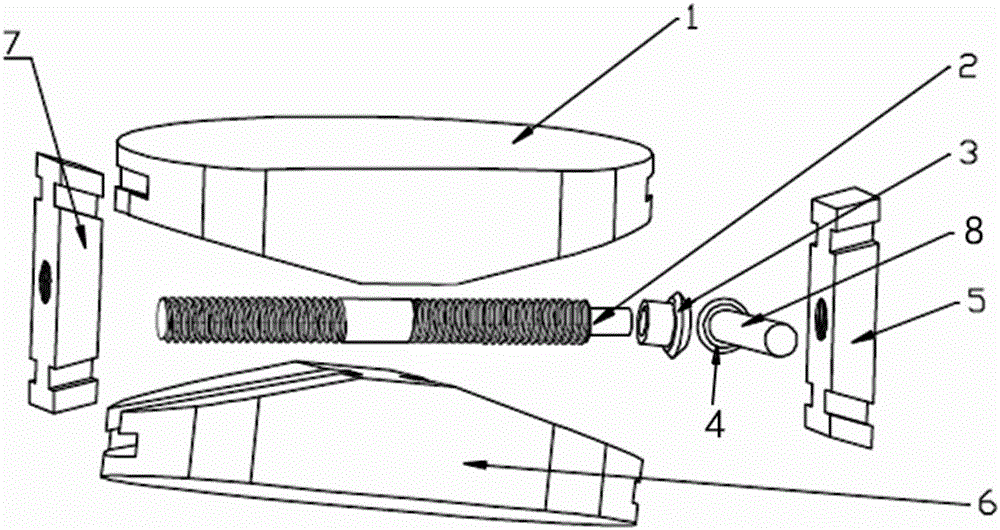

Extract and mechanical properties measurement method of bone trabecula and measurement mechanism

InactiveCN101158679AAvoid damageSubsequent measurement results are authentic and reliableUsing mechanical meansMaterial analysisMeasurement deviceBiomechanics

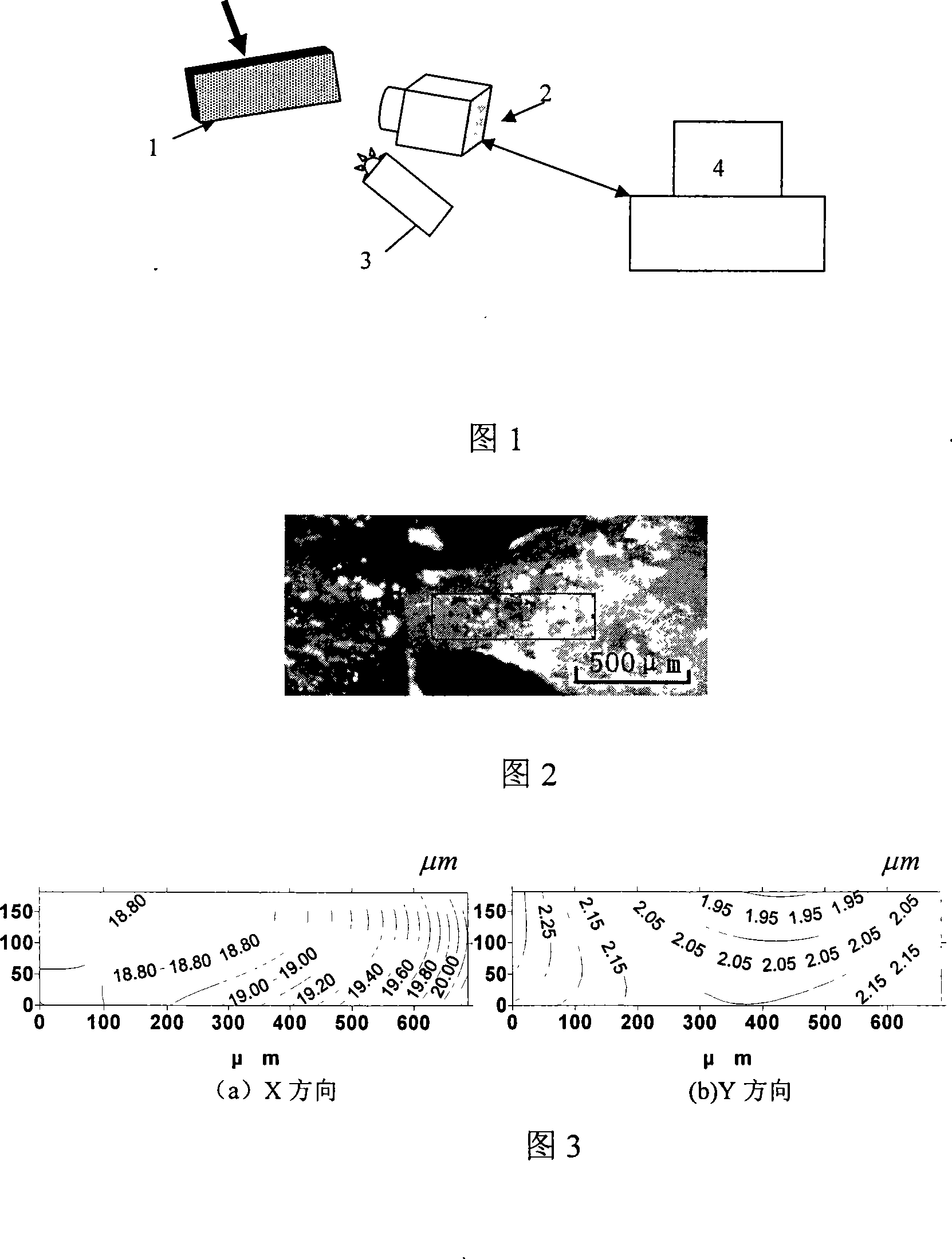

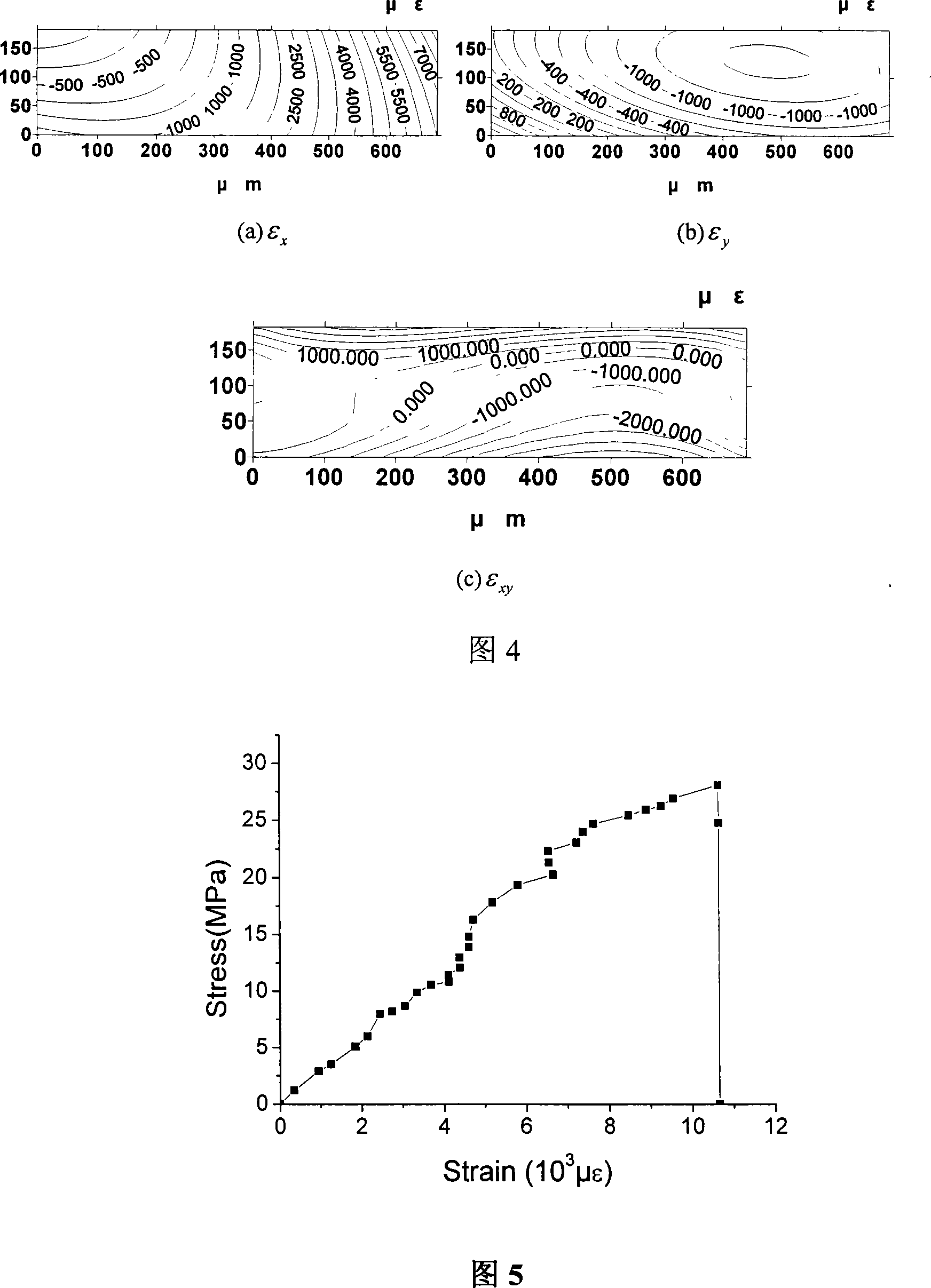

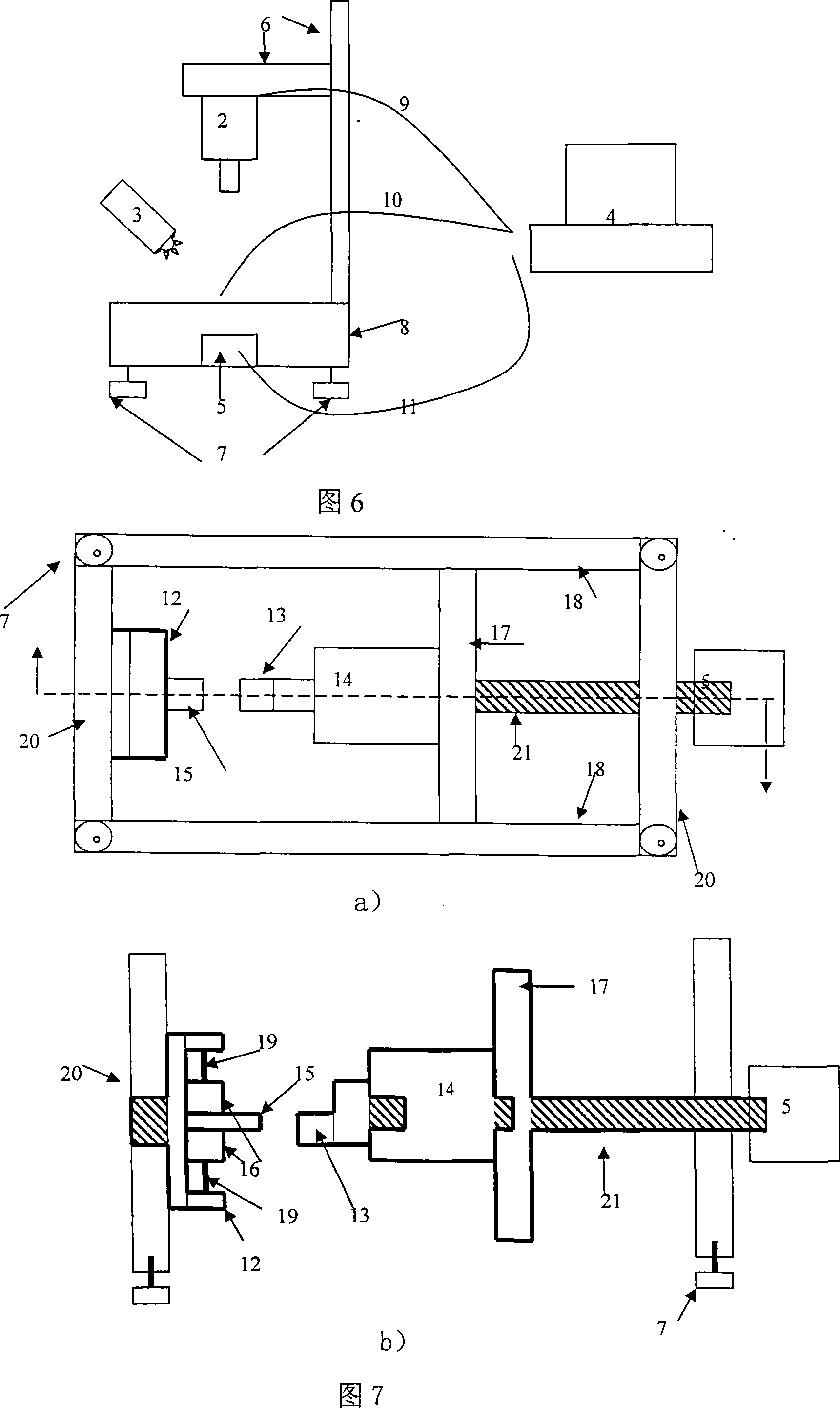

The invention relates to an extracting of a bone trabecula and a test method and a device of mechanical property, which belongs to the biological mechanics experiment technical field. The method comprises: 1. the bone is cut into a plurality of small blocks at the length of the bone trabecula; 2. the marrow in the middle of each small spongy bone block is rejected clearly and the spongy bone structure is only left; 3. a small spongy bone block which has an intact bone trabecula is chosen and the bone trabecula around the intact bone trabecula is cut away; 4. the bone trabecula is stretched and compressed at the direction paralleled with a loading force, and the two ends of the bone trabecula are fixed; 5. the CCD camera is aimed to the bone trabecula so as to lead the picture of the bone trabecula in the CCD to be clear; 6. the displacement of the stretching or compressing of the bone trabecula is controlled; 7. the picture and the load of the bone trabecula in each time quantum are recorded synchronously; 8. the displacement field and the strain field of each load is worked out according to DSCM; namely the poisson ratio of the material and the strain curve of the strain of the bone trabecula can be obtained. The invention can minimize the damage greatly, and lead a plurality of mechanical property parameters to be more correct.

Owner:TSINGHUA UNIV

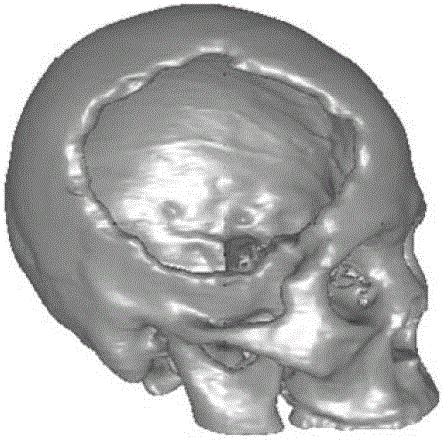

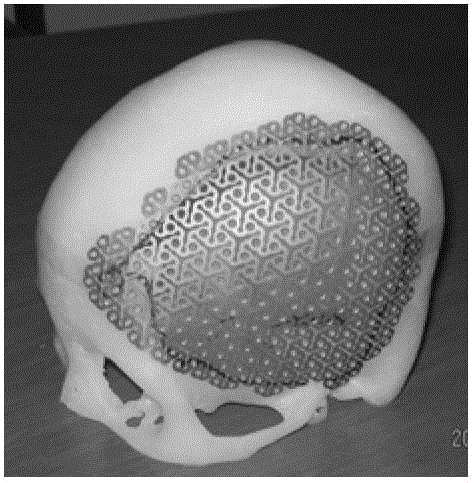

Bionic design method of skull tissue engineering scaffold

InactiveCN102973334ASuitable for growthSuitable for requirementsBone implantPatch modelThree dimensional model

The invention discloses a bionic design method of a skull tissue engineering scaffold, which comprises the following steps of: implementing three-dimensional reconstruction according to naturally aired skull micro CT (computed tomography) data to obtain a skull sample three-dimensional model; implementing statistics and analysis for the skull sample three-dimensional model to build a skull microporous structure parametric model; implementing skull scaffold bionic design through the skull microporous structure parametric model; and generating a bionic scaffold. Based on measurement of a natural skull micro CT image, the method raises three elements of a space network architecture, a cavity and a connection tube to implement the bionic design for the scaffold; an obtained internal microporous architecture is similar to a bone trabecula of a natural skull, and the average hole scale is about 500-700 microns, so that bone cell growth and climbing demands are satisfied; and moreover, the skull scaffold, obtained by intersection operation with a patch model of a coloboma part, can be matched with an adjacent part, so that the communication among holes is realized, and a bone structure of a true skull is suited better.

Owner:TIANJIN UNIV

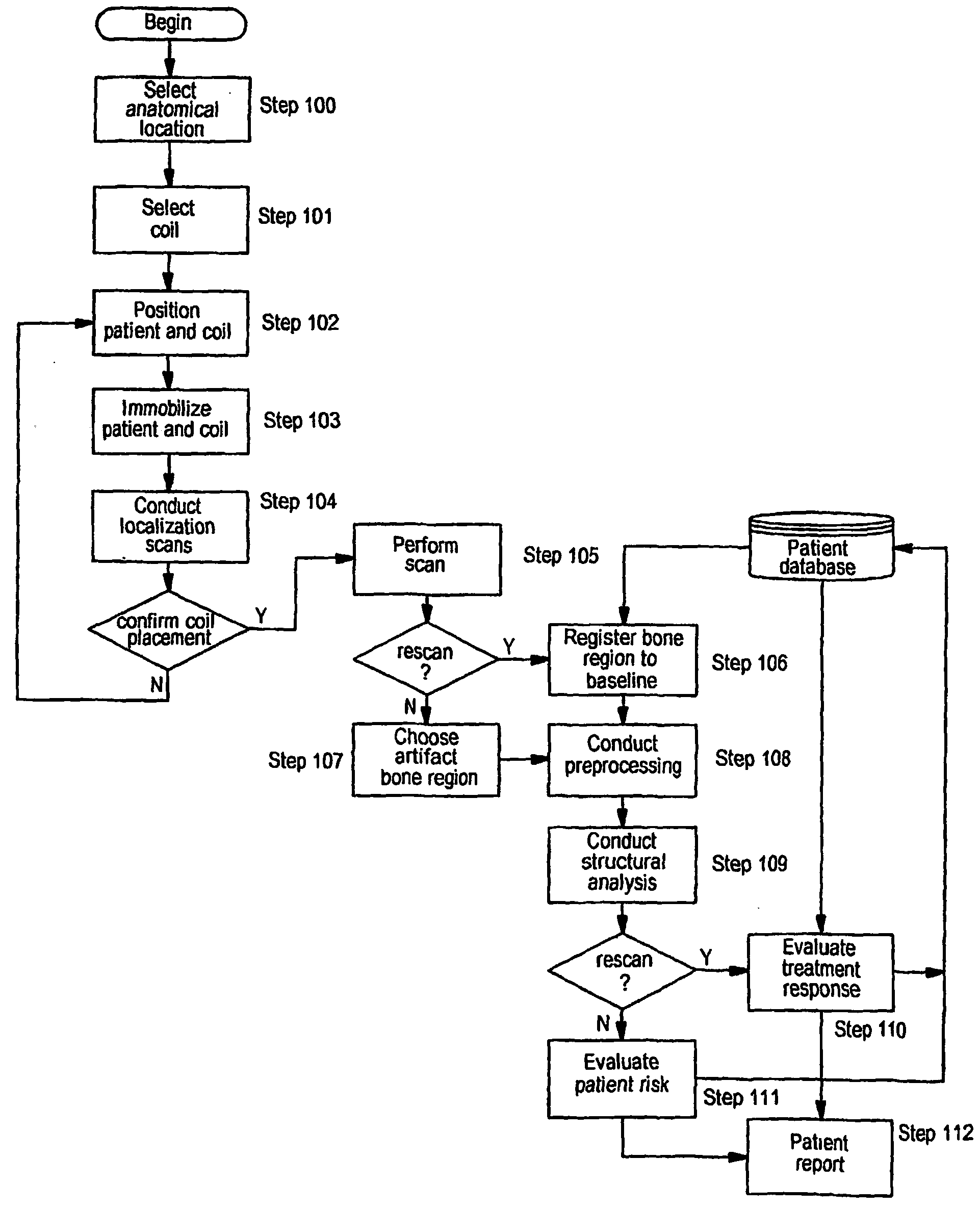

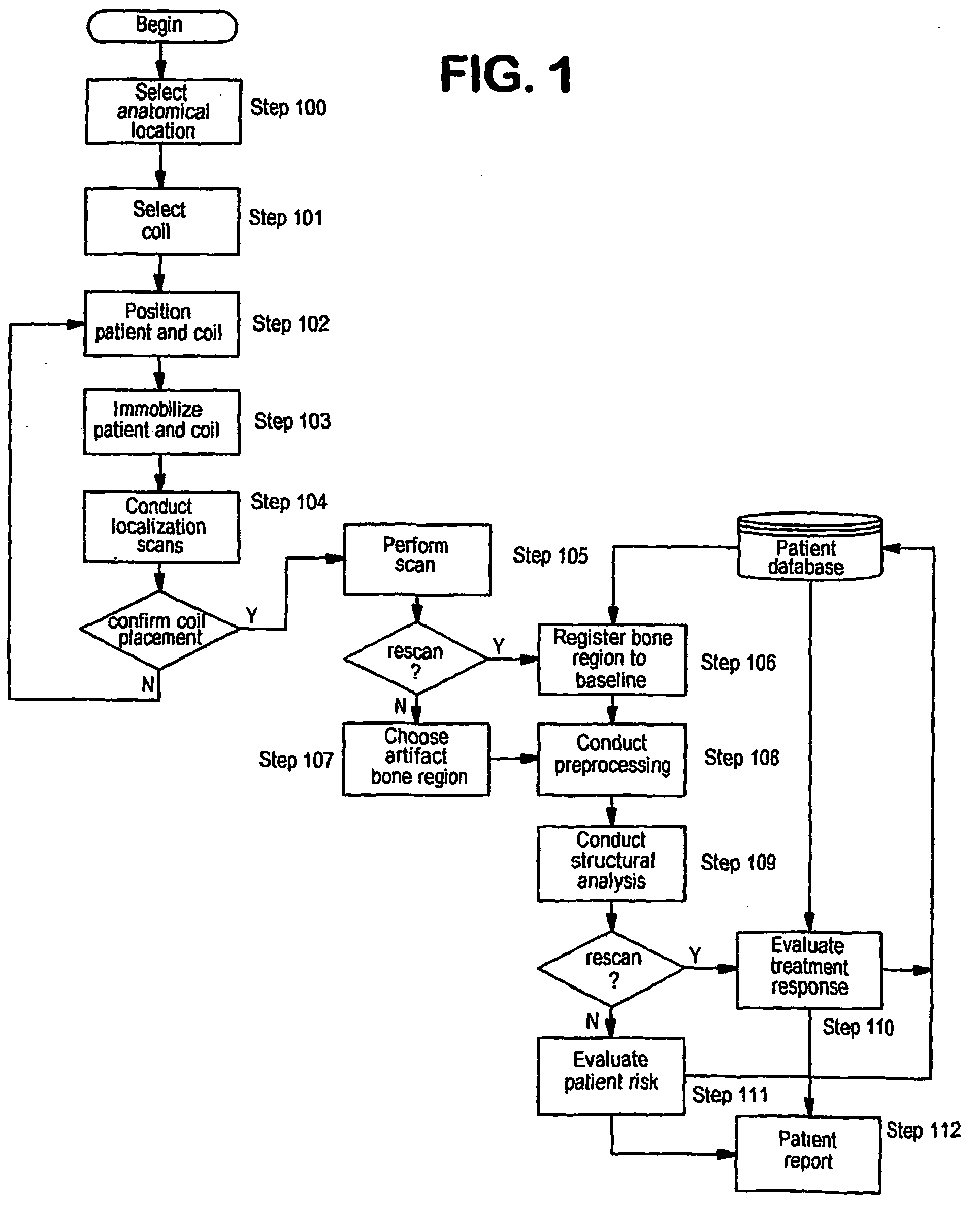

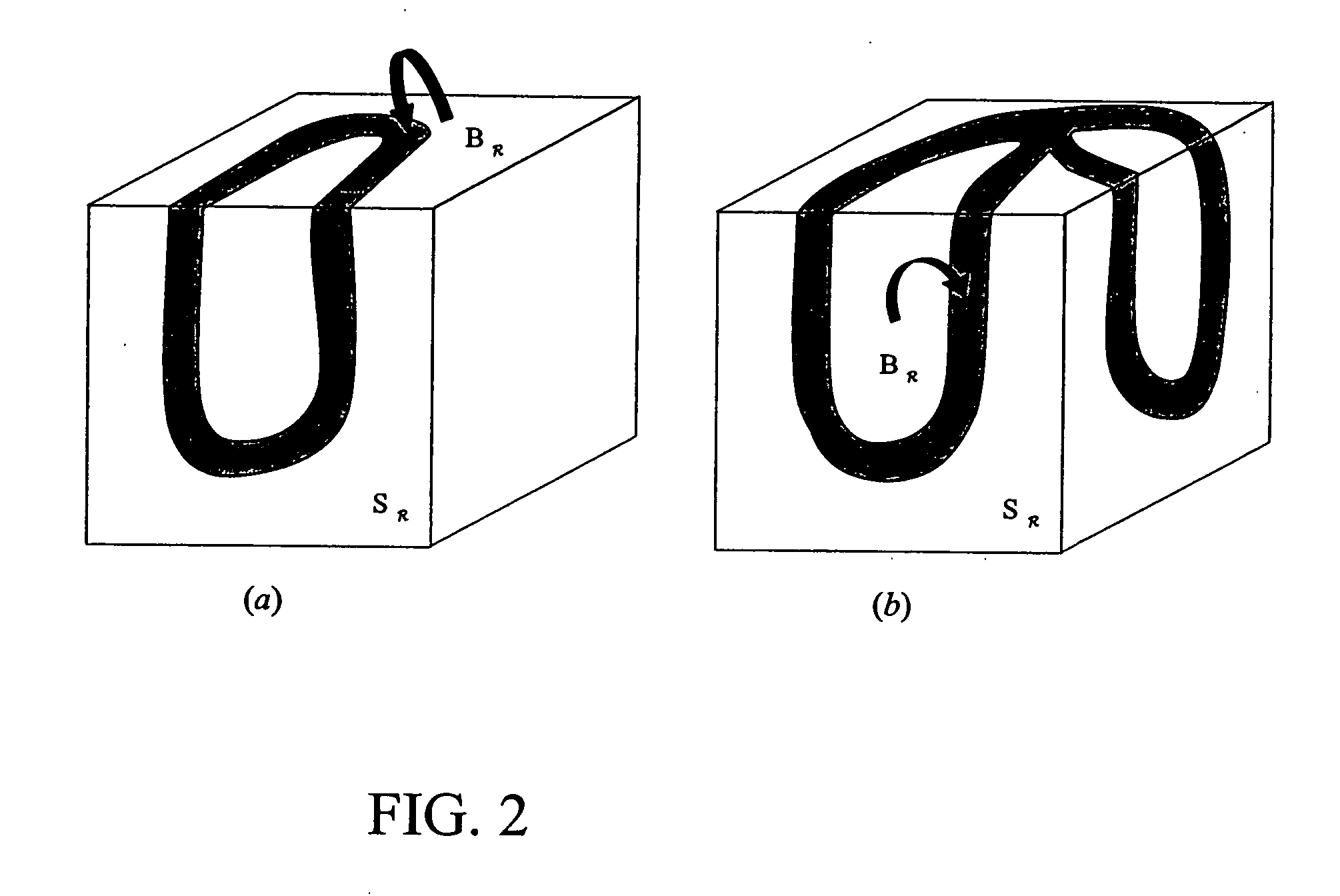

Virtual bone biopsy

ActiveUS20050031179A1Reduce noise imagingReduce noiseImage enhancementImage analysisResonanceMri image

The present indention comprises a system and method for analyzing trabecular bone structure. A means for scanning the trabecular bone using a magnetic resonance image (MRI) scanner generates bone image data, which is then processed including correcting, deshadi4 and reducing noise in the image data.

Owner:PENNSYLVANIA THE TRUSTEES OF THE UNIV OF

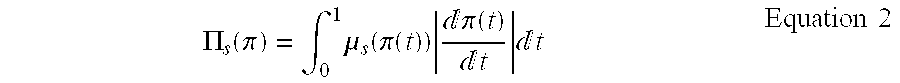

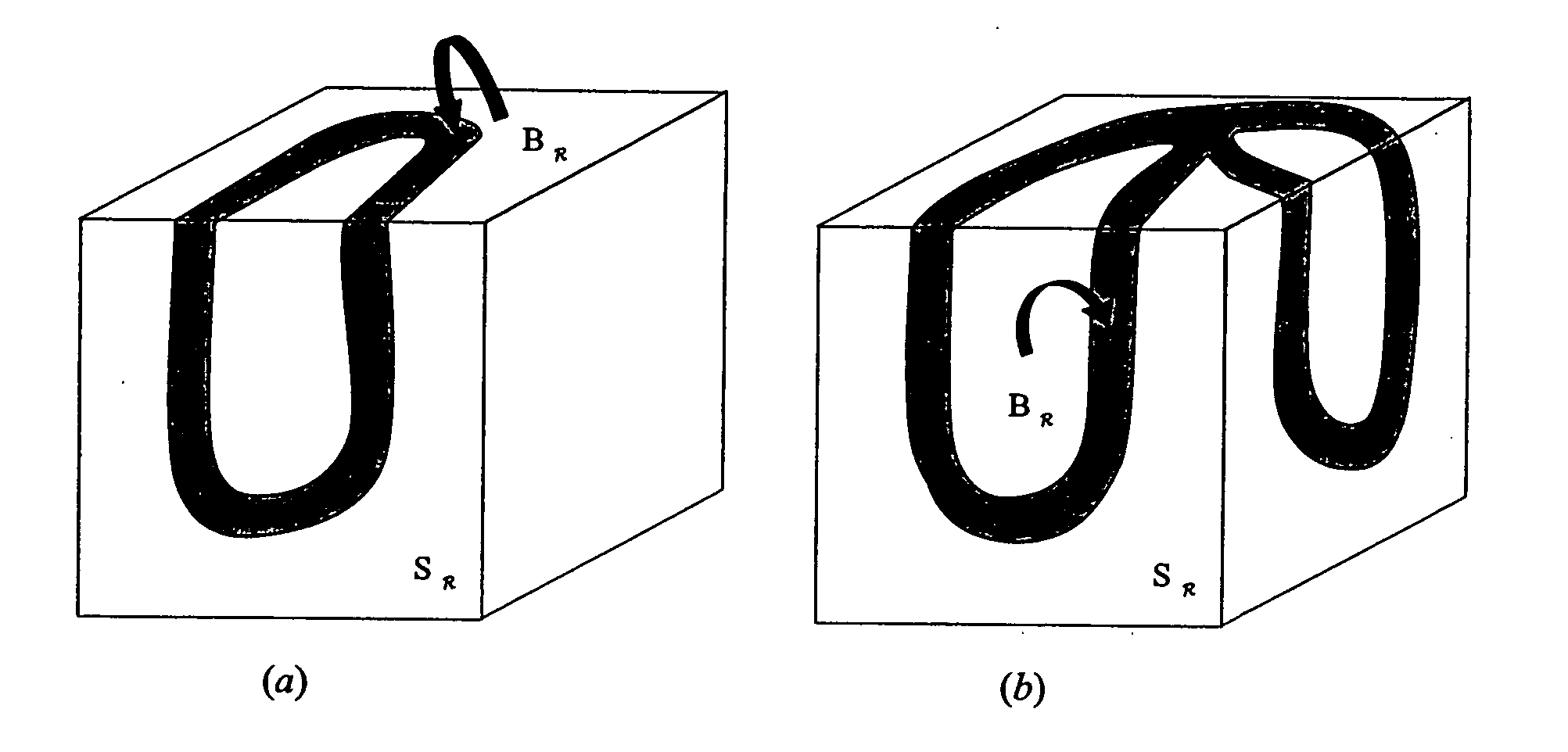

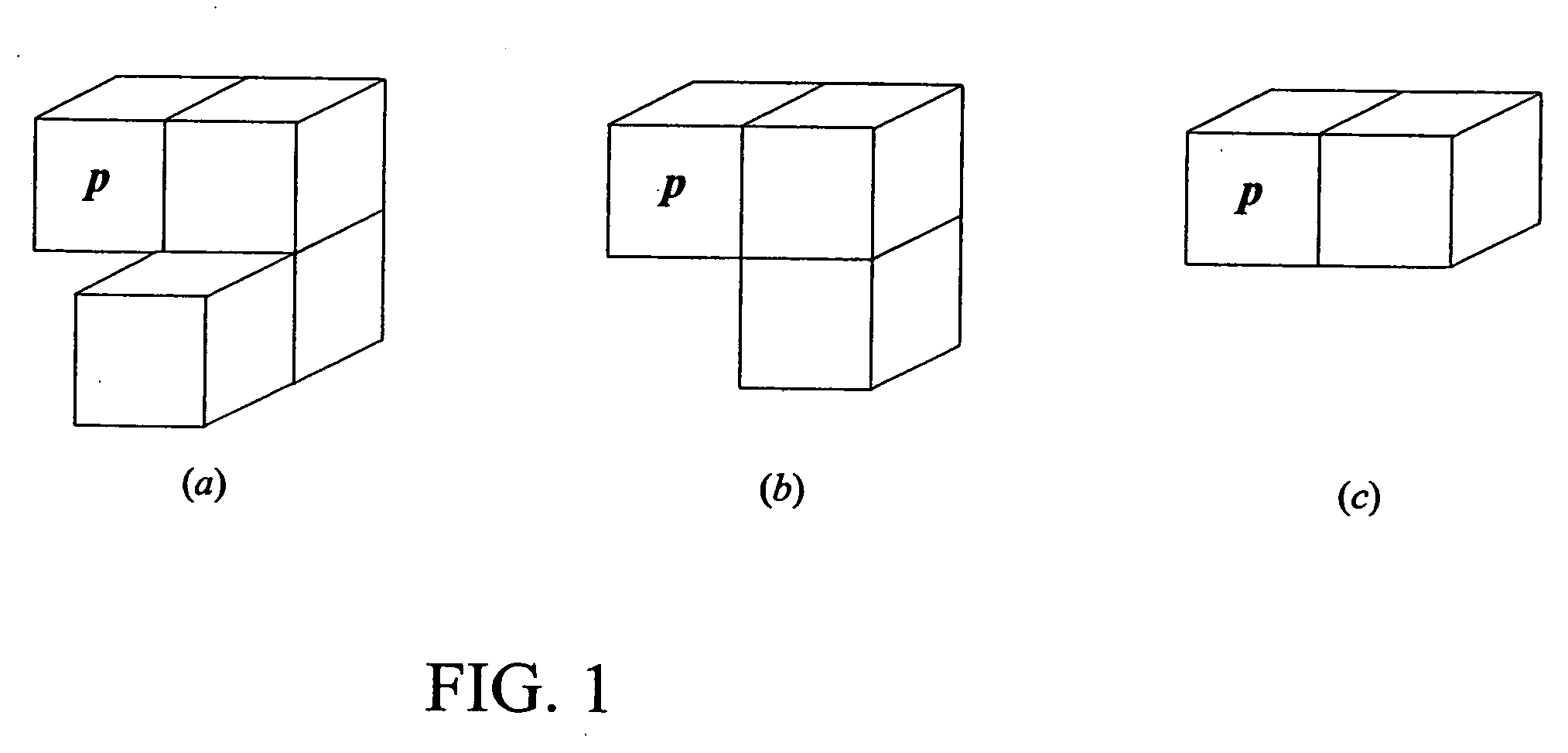

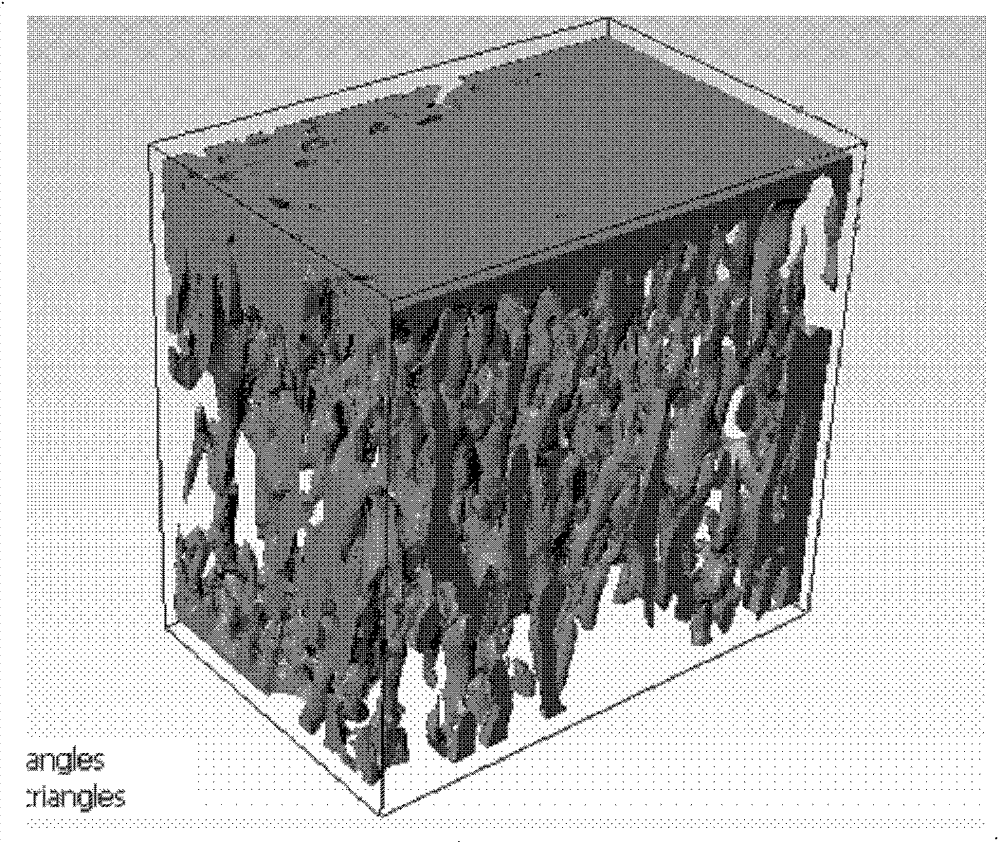

Digital topological analysis of trabecular bone MR images and prediction of osteoporosis fractures

The invention provides method, system and device for determining trabecular bone structure and strength by digital topological analysis, and offers, for the first time, a demonstration of superior associations between vertebral deformity and a number of architectural indices measured in the distal radius, thus permitting reliable and noninvasive detection and determination of the pathogenesis of osteoporosis. A preferred embodiment provides imaging in three dimension of a region of trabecular bone, after which the 3D image is converted into a skeletonized surface representation. Digital topological analysis is applied to the converted image, and each image voxel is identified and classified as a curve, a surface, or a junction; and then associated with microarchitectural indices of trabecular bone to quantitatively characterize the trabecular bone network. The invention is applicable in vivo, particularly on human subjects, or ex vivo.

Owner:THE TRUSTEES OF THE UNIV OF PENNSYLVANIA

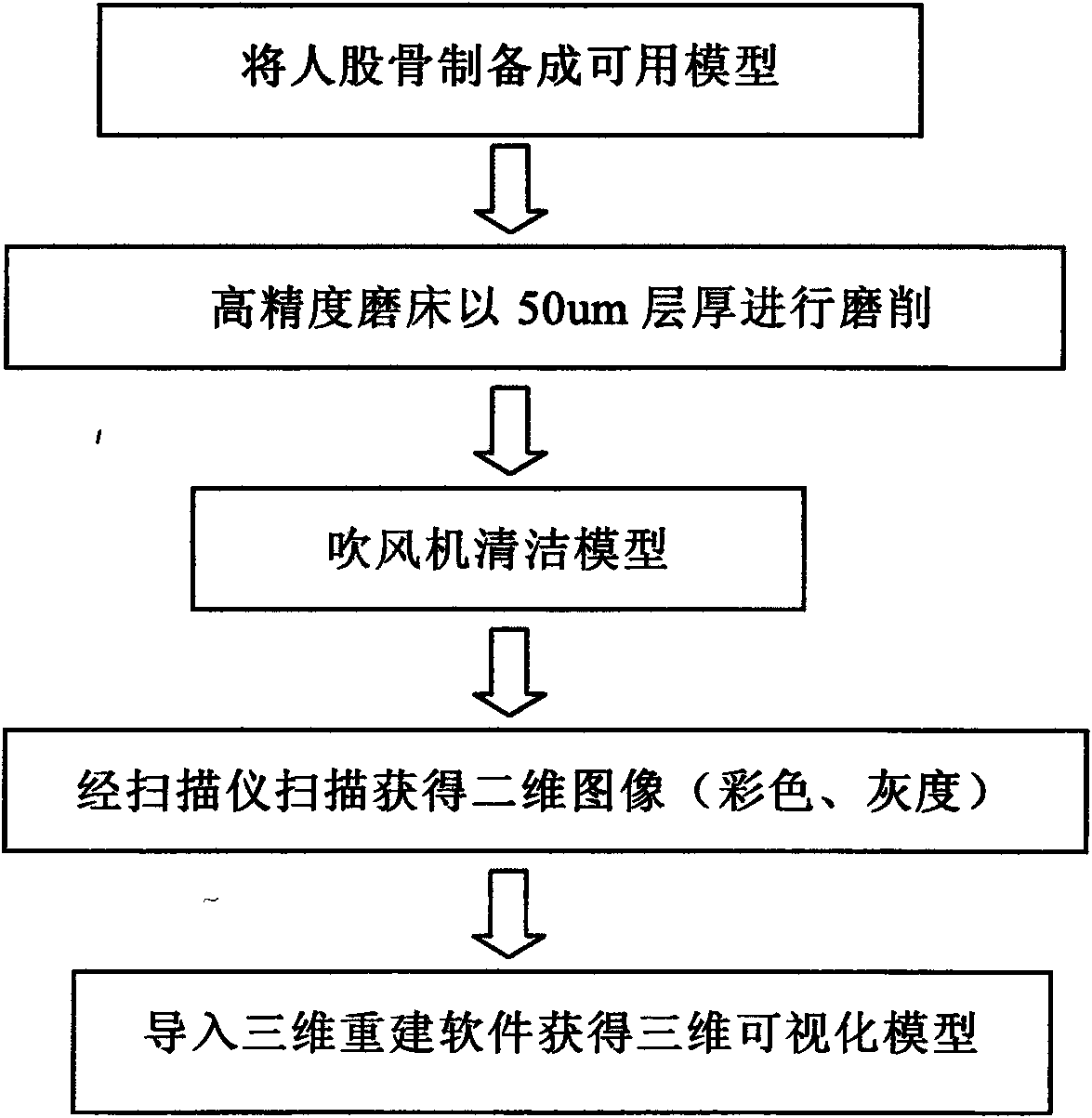

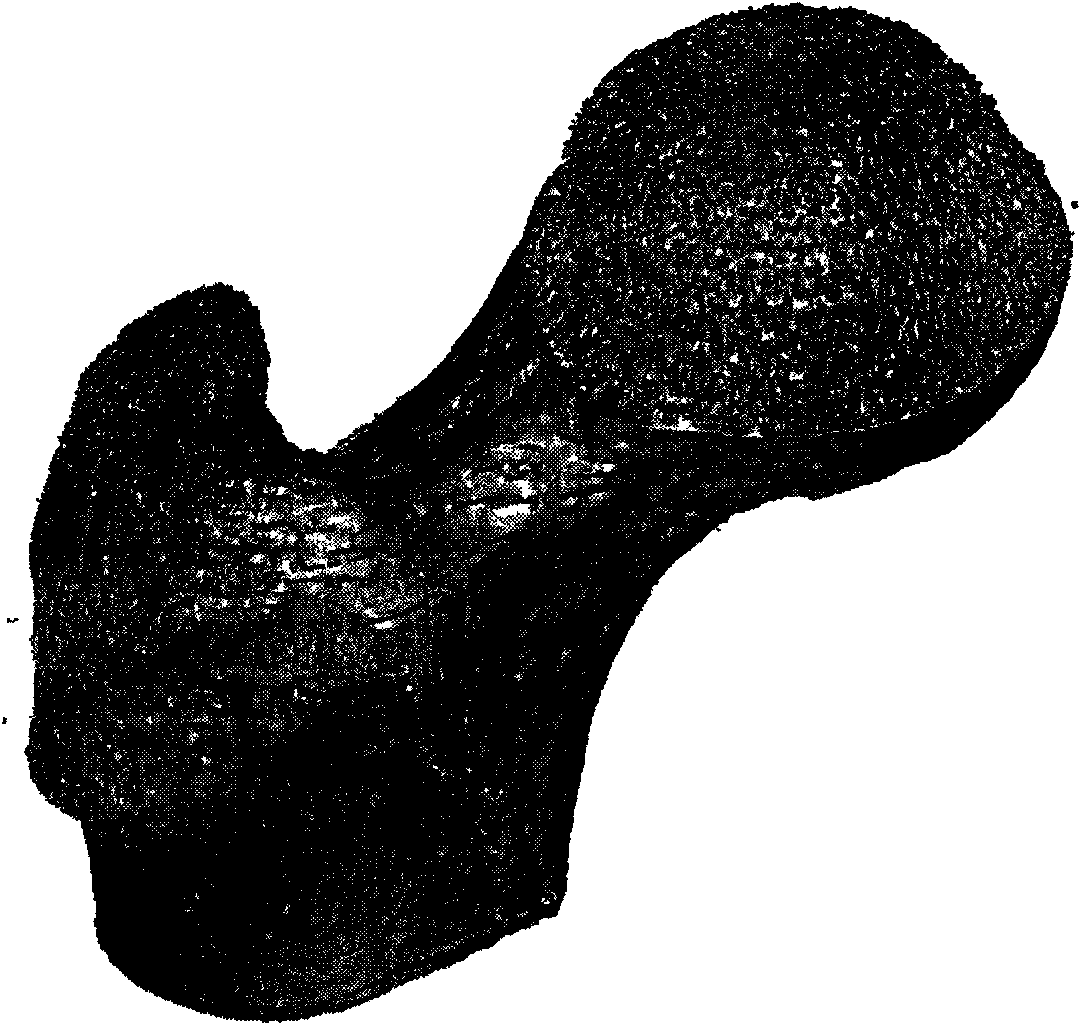

Method for making three-dimensional visualization model of internal structure of bone

The invention is a method for making a three-dimensional visualization model of the internal structure of bone. In the method, a dry bone specimen is embedded and fixed by transparent polymethyl methacrylate (PMMA) to form a model specimen, and then the cross-section of the specimen is ground layer by layer, two-dimensional grayscale images and true color images are scanned and recorded layer by layer, and then three-dimensional medical reconstruction software is used to obtain high-precision three-dimensional visual model of a proximal bone structure. The invention can be applied to three-dimensional reconstruction of bones of human bodies and animals, thereby obtaining the high-precision three-dimensional visual model which can objectively, truly and completely reflect the proximal bone structure. The method can carry out certain evaluation on the structural form of bone trabecula as well as the connectivity of three-dimensional bone trabecular, and can determine the structural parameters of bone trabecular, thus providing scientific basis for medical research and clinical care.

Owner:GENERAL HOSPITAL OF TIANJIN MEDICAL UNIV

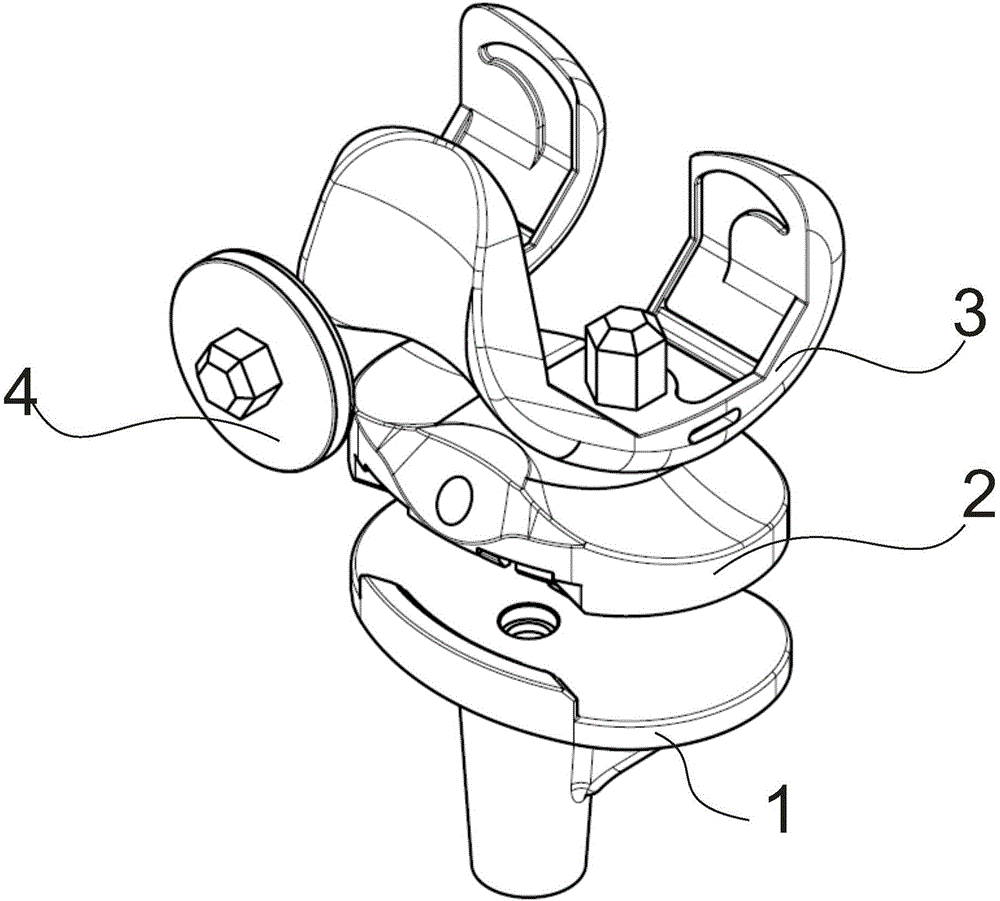

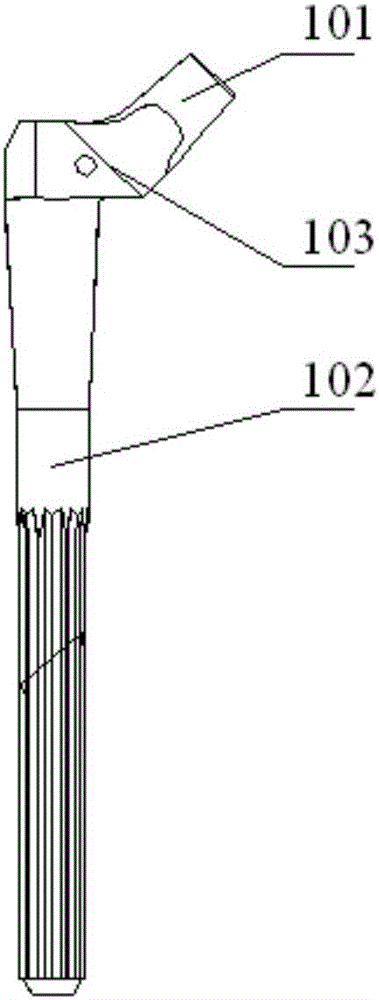

Bone trabecula hip joint system

ActiveCN105055051AEasy to integrateExtended service lifeJoint implantsHip jointsPorosityOsseointegration

The invention discloses a bone trabecula hip joint system. The system comprises a series of bone trabecula assembled femoral components, caput femoris, bone trabecula oversleeves, bone trabecula assembled acetabular cups and bone trabecula acetabulum cushion blocks. The surface structures of the bone trabecula assembled femoral components, the caput femoris, the bone trabecula oversleeves, the bone trabecula assembled acetabular cups and the bone trabecula acetabulum cushion blocks are all metal bone trabecula structures and manufactured by means of the metal 3D printing technology, the structural form of holes and porosity can be accurately controlled, a plurality of specifications are available, and assembly can be conducted freely. The system has the advantages that fastness and effectiveness are realized, postoperation osseointegration is facilitated, service life is prolonged, postoperation revision rate is reduced, serious femur and acetabulum deformation is effectively solved, complicated joint primary replacement surgery and revision surgery under the condition of various forms of bone defects can be conducted, and the requirements of various patients for prosthesis customization are met.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

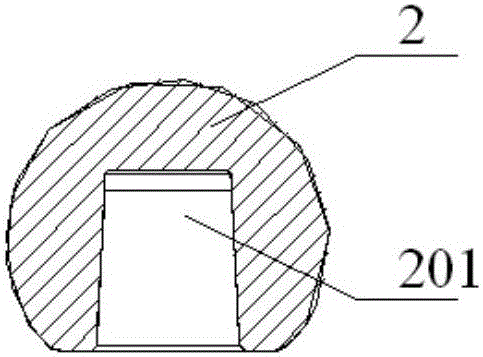

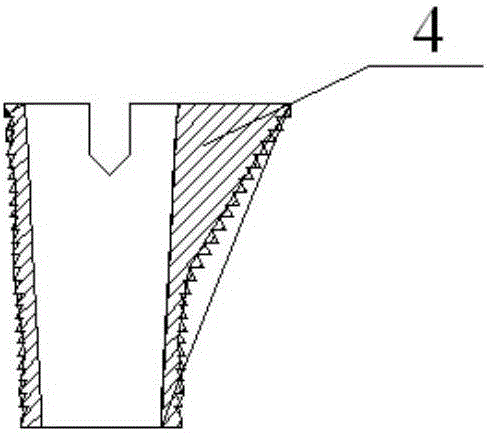

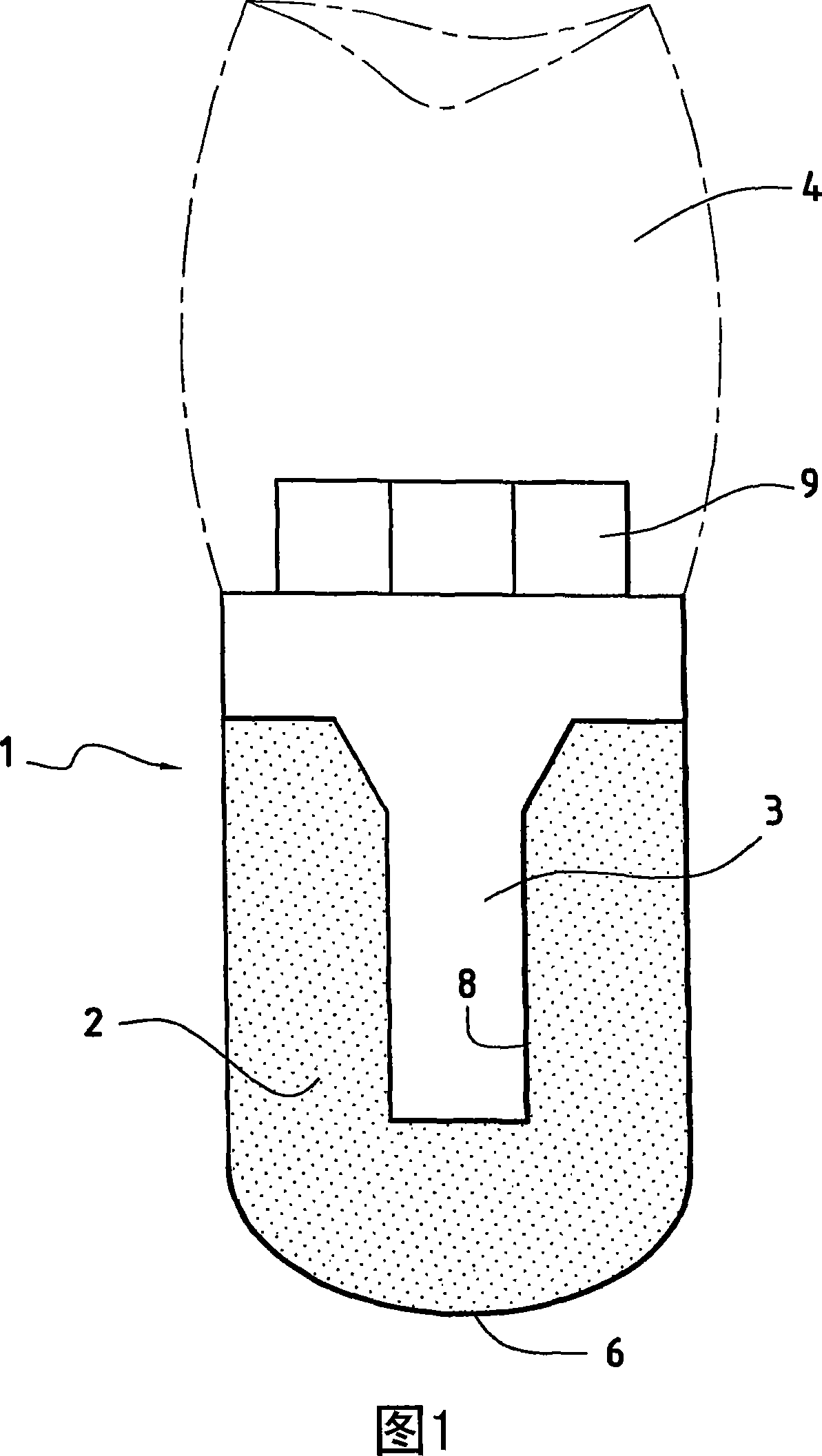

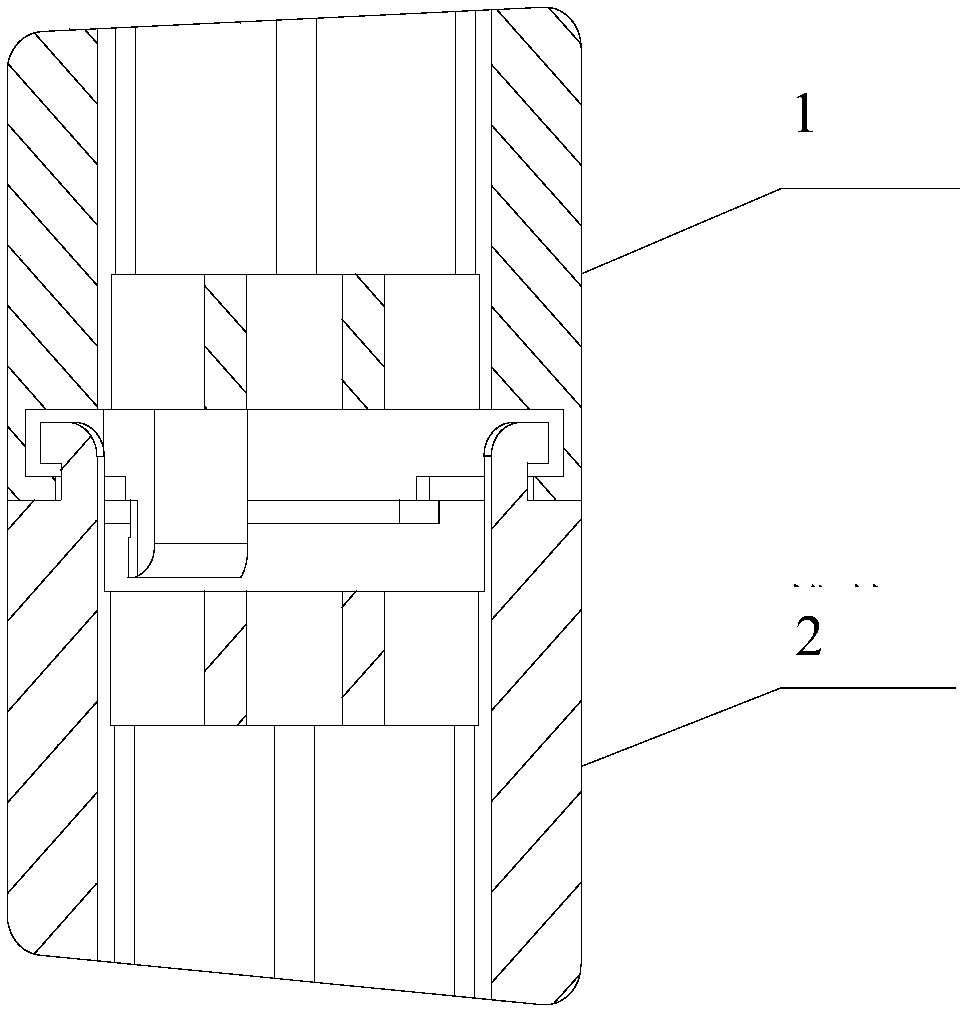

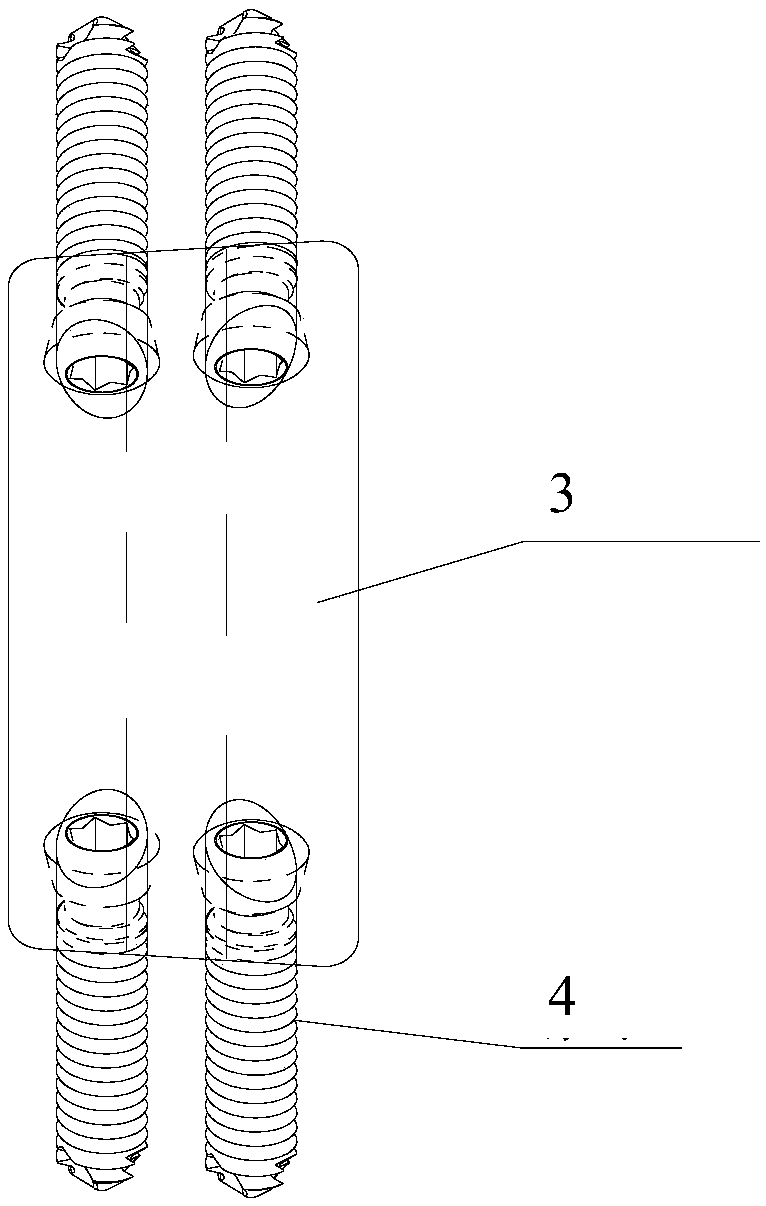

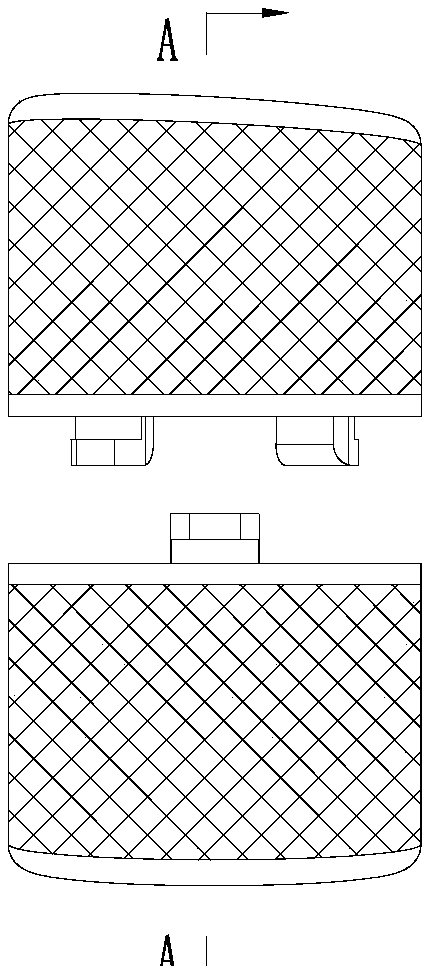

Dental implant comprising a porous trabecular structure

The invention relates to a dental implant comprising a biocompatible porous solid body which is equipped with at least one receiving bore (8) for a part that is used to connect a dental prosthesis. The invention is characterised in that the biocompatible porous solid body (2) is made from one material having a trabecular structure, such that the exterior of the porous solid body and the interior thereof are communicated with one another.

Owner:VITAL IMPLANT

Preparation method of porous titanium-alloy femoral head support rod in bionic bone trabecula structure

ActiveCN104645419AReduce loosenessAchieve slow release effectJoint implantsFemoral headsSelective laser meltingRight femoral head

The invention relates to a preparation method of a porous titanium-alloy femoral head support rod in a bionic bone trabecula structure. The support rod is prepared from titanium alloy powder by printing by adopting an SLM (selective laser melting) or EBM (electron beam melting) technology, wherein the titanium alloy powder serves as a raw material, has low modulus of elasticity and has a particle size of less than 45mu m. The structure of the support rod structure is similar to that of the human cancellous femoral neck bone trabecula so that the modulus of elasticity of the support rod is made to be similar to that of the human femoral neck as much as possible and the phenomenon that the support rod becomes loose can be reduced effectively. In addition, the surface of the support rod is provided with a poly(lactic-co-glycolic acid (PLGA) nanoparticle, bone morphogenetic protein-2 (BMP-2) and a vascular endothelial growth factor (VEGF) complex so that a growth factor slow-release effect can be achieved and the bone tissue can grow into the support rod.

Owner:维度(西安)生物医疗科技有限公司

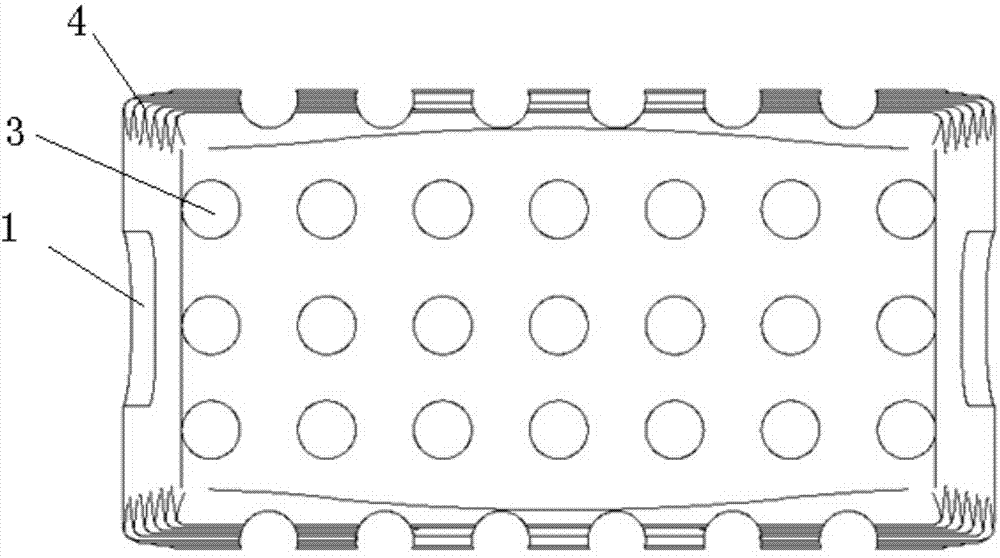

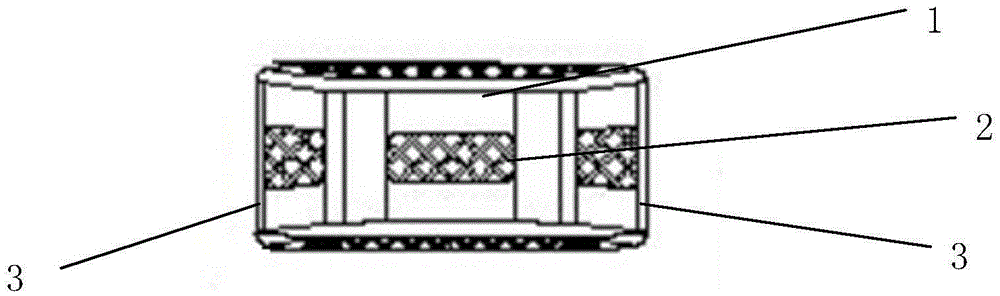

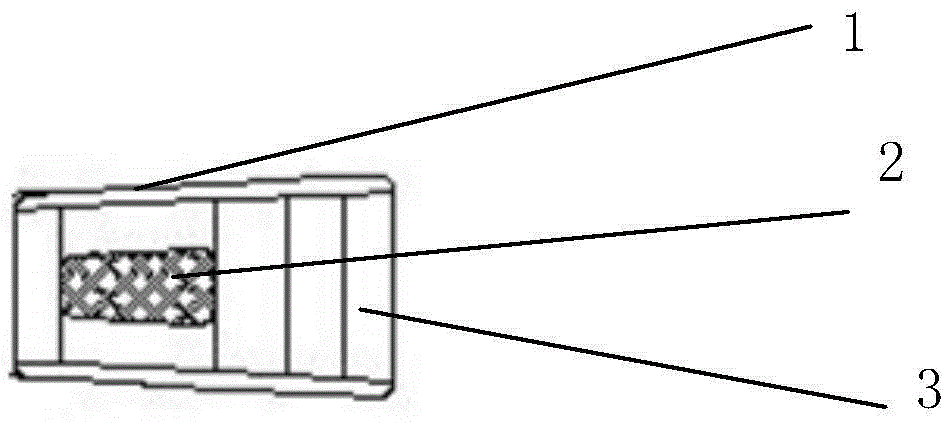

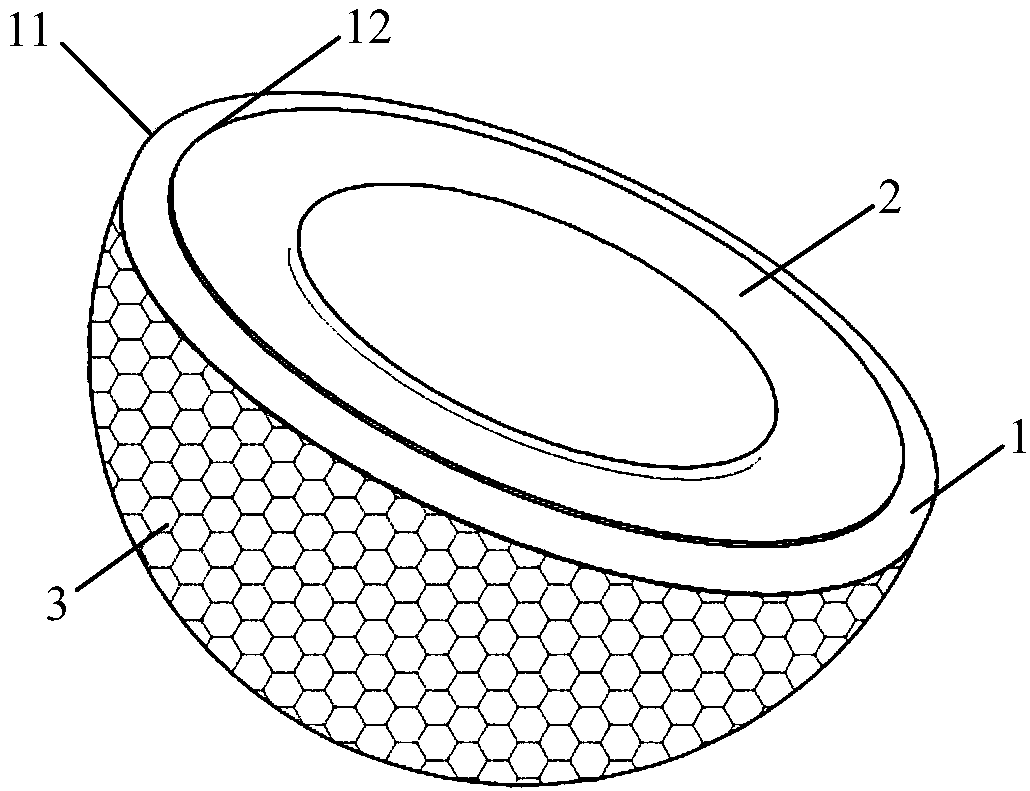

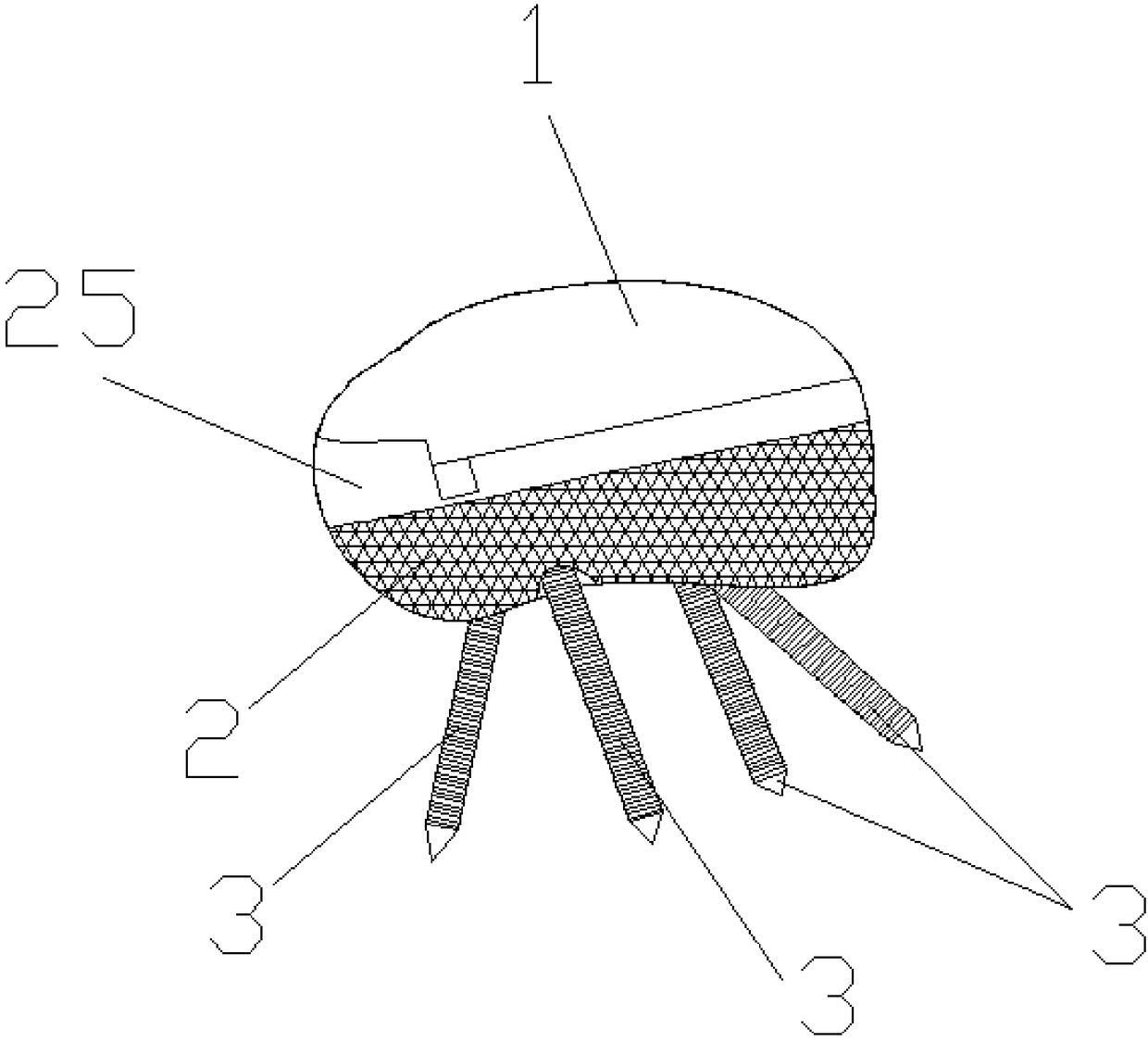

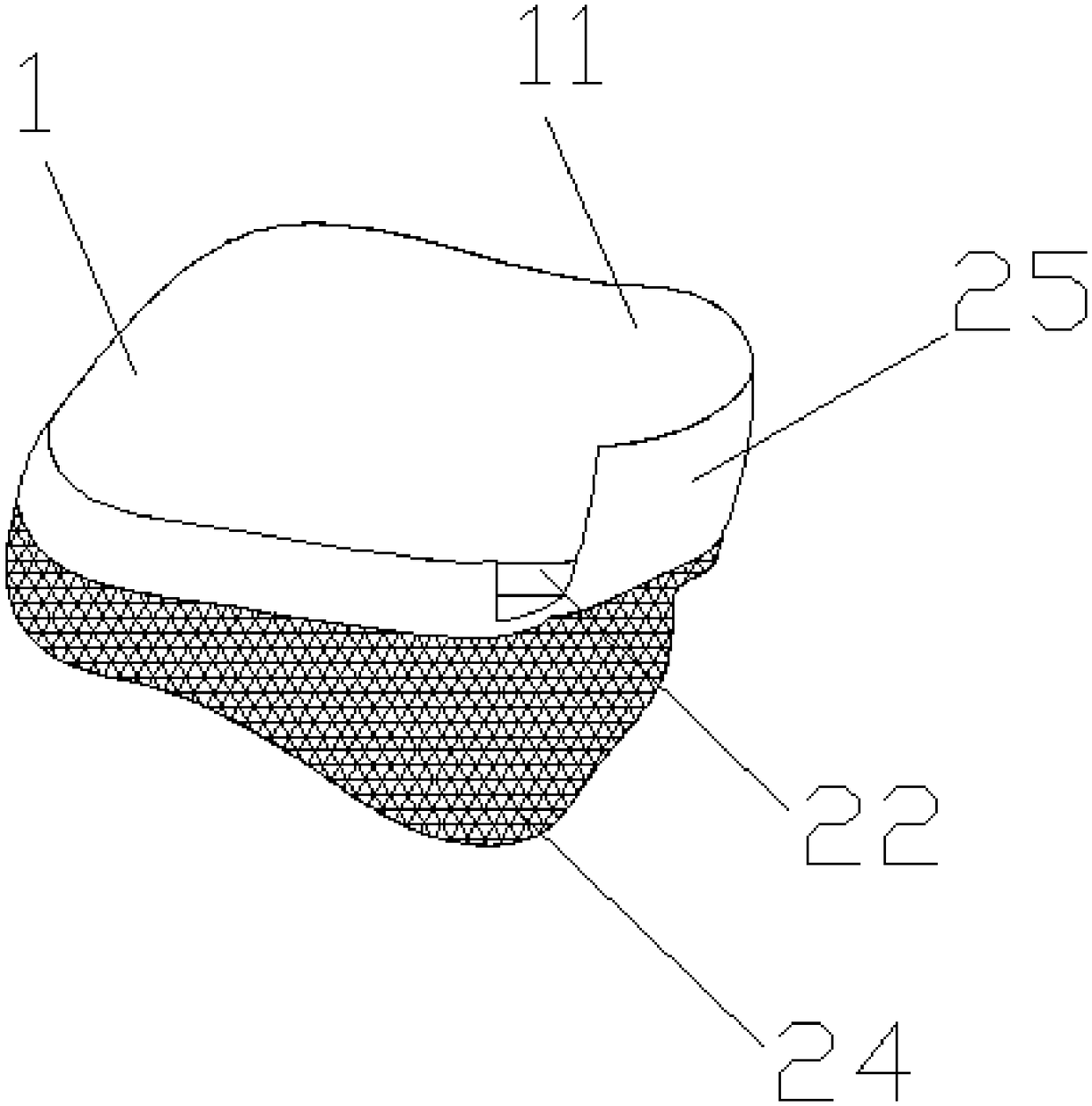

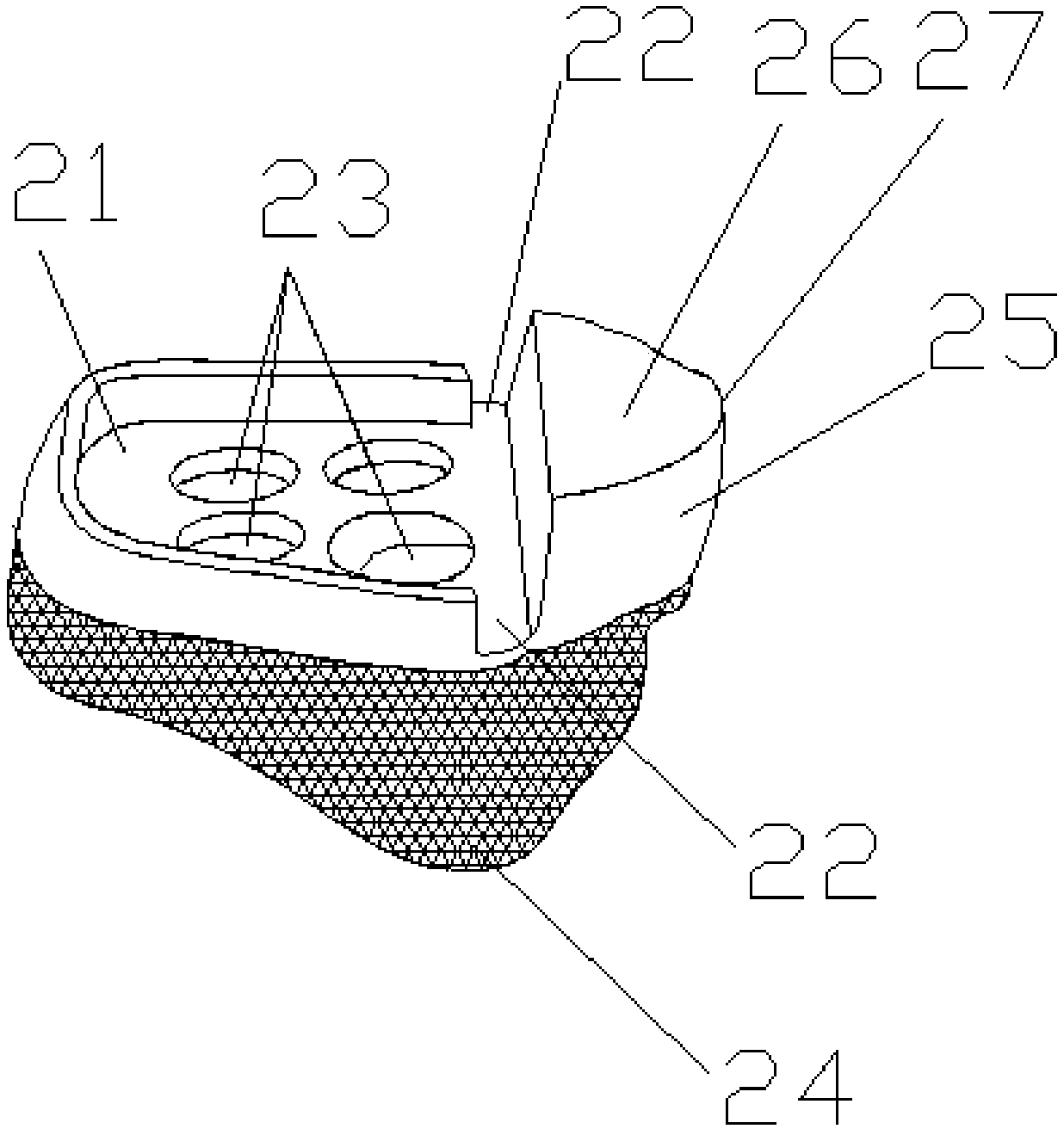

3D print type artificial bone trabecula structure cervical fusion device and preparing method and application thereof

InactiveCN105581860APromote productionImprove mechanical propertiesAdditive manufacturing apparatusSpinal implantsCervical fusionsArtificial bone

The invention discloses an anterior spinal and cervical 3D print type artificial bone trabecula structure cervical fusion device. The device is characterized by comprising an entity support, the entity support comprises a horizontal plane entity support body (1) and an axial position entity support body (3), and a porous structure (2) is arranged in the middle of the entity support. The porous structure simulating the cancellous bone of the human body is manufactured in the 3D mode, a bone ingrowth support is provided, and the osteogenesis process is promoted; support pillars are additionally arranged on the periphery and on the sides to improve mechanical property, the elasticity modulus of the entity support is made to be close to that of a contact surface, and then shielding is avoided. Implantation of human bone is not needed, bone taking amount in surgery can be further reduced, the number of operative wounds is reduced, and surgery can be finished in a minimally invasive mode.

Owner:BEIJING ZHONGNUO HENGKANG BIOTECH

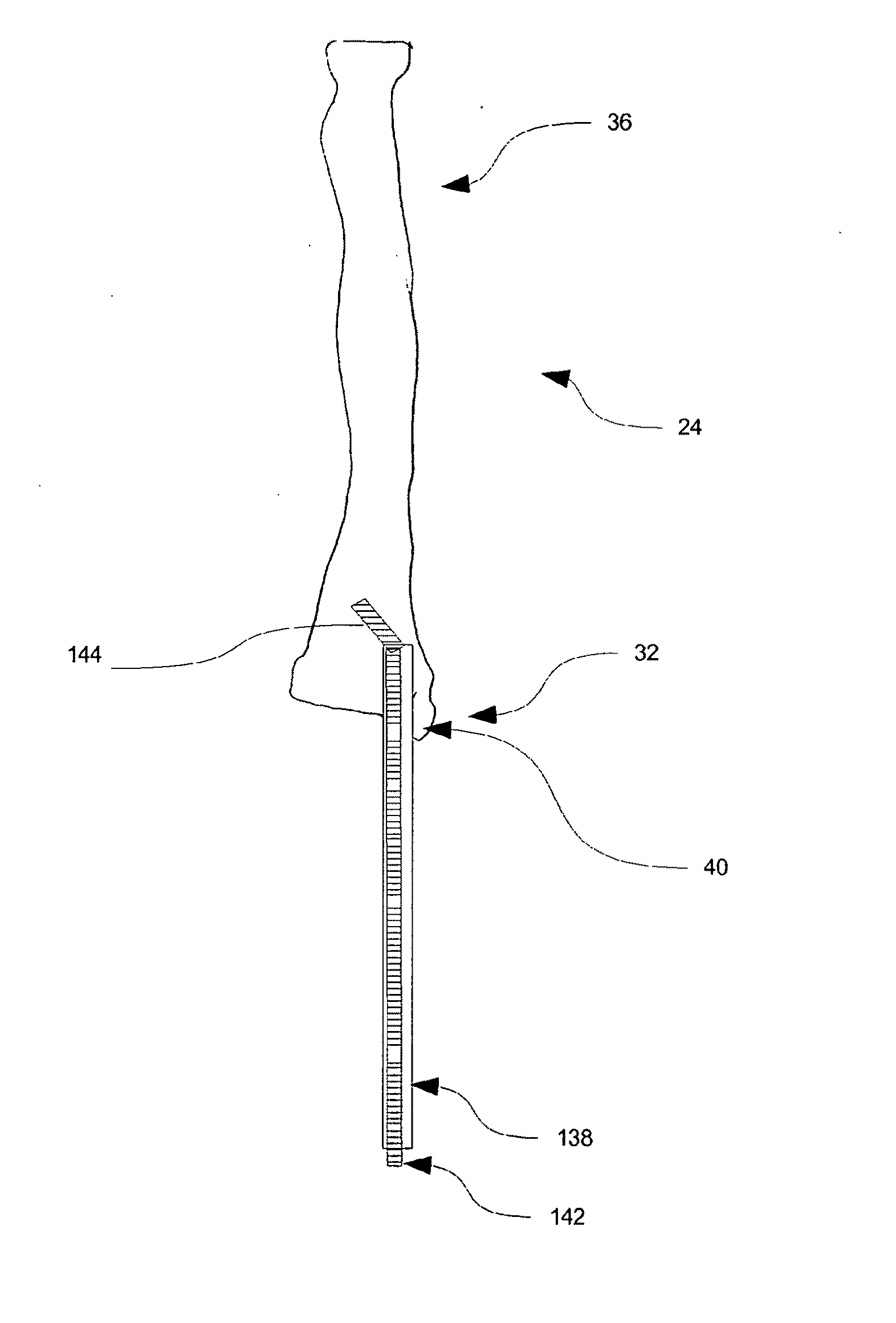

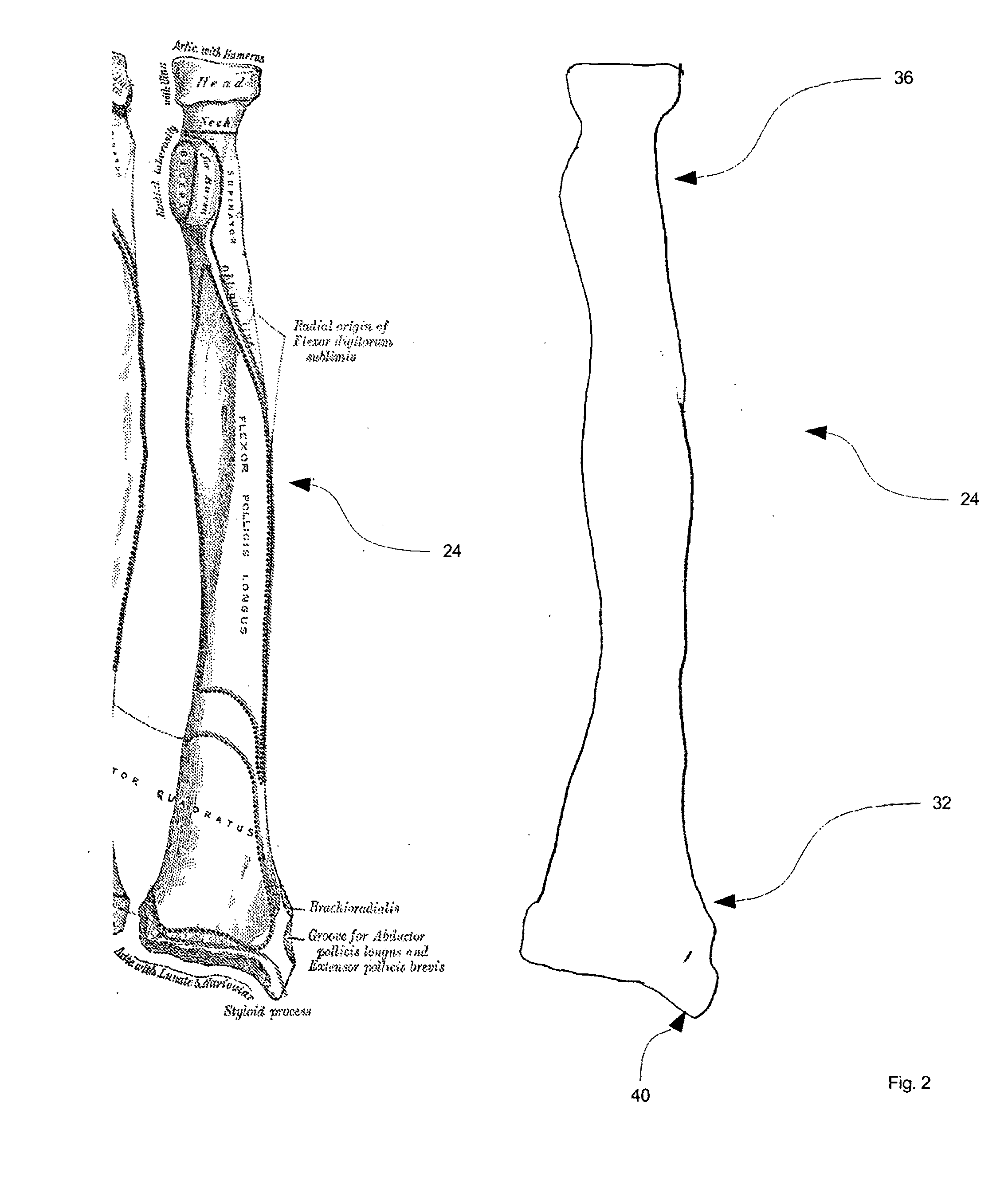

Method and kit for intra osseous navigation and augmentation of bone

A method and kit for navigation and augmentation of bone is provided. In an embodiment, the method comprises creating a passageway in an end of a long bone and inserting a cannula or the like into the passageway. The cannula, or other instrument inserted through the cannula, can be used to break trabecula within the long bone. The cannula can also be used to inject a bone cement into the long bone. Where a biologically active bone cement is used, the method can also comprise adminstering a medication, such as PTH, to stimulate integration of the bone cement with the long bone.

Owner:MURPHY KIERAN P

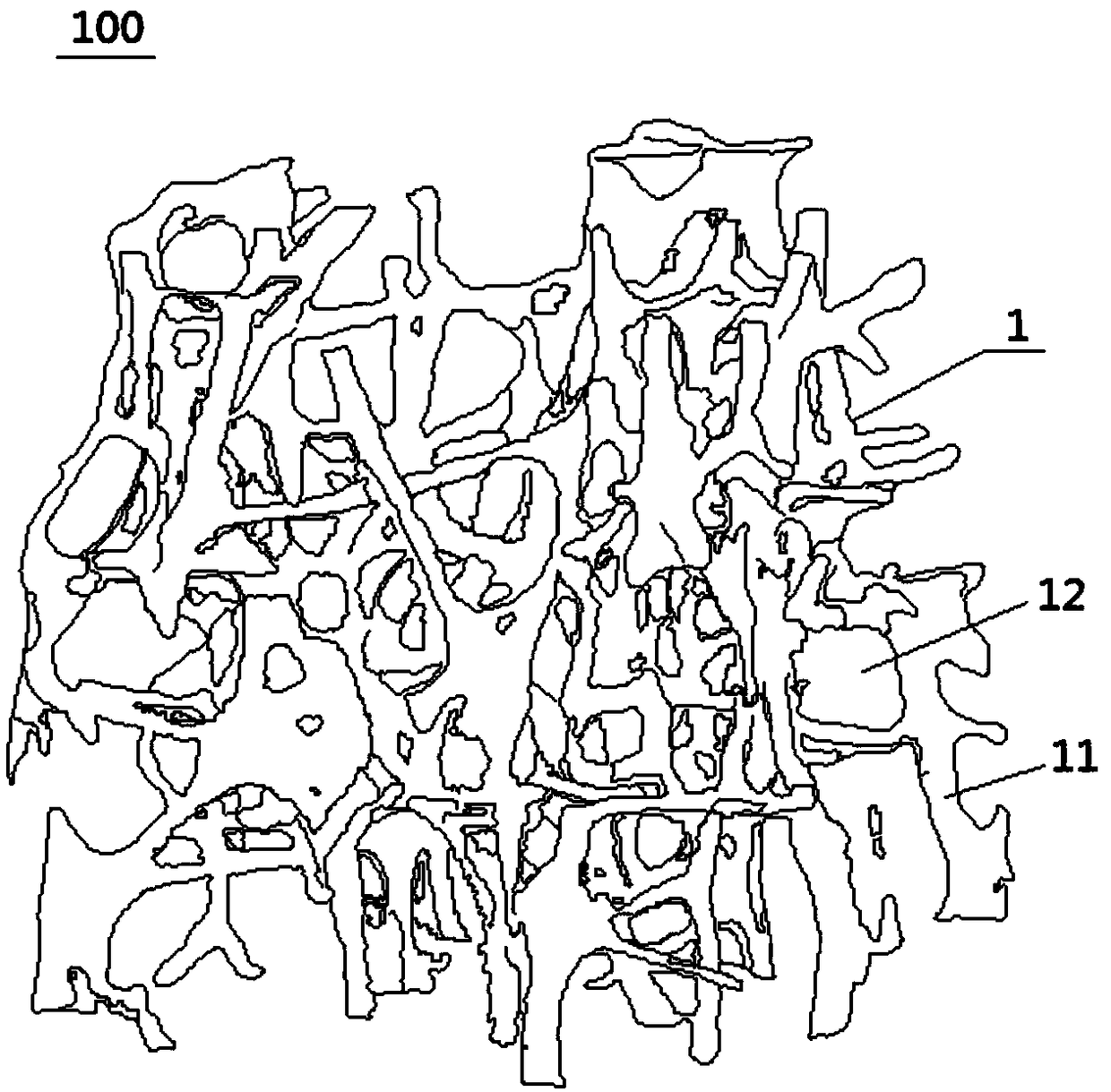

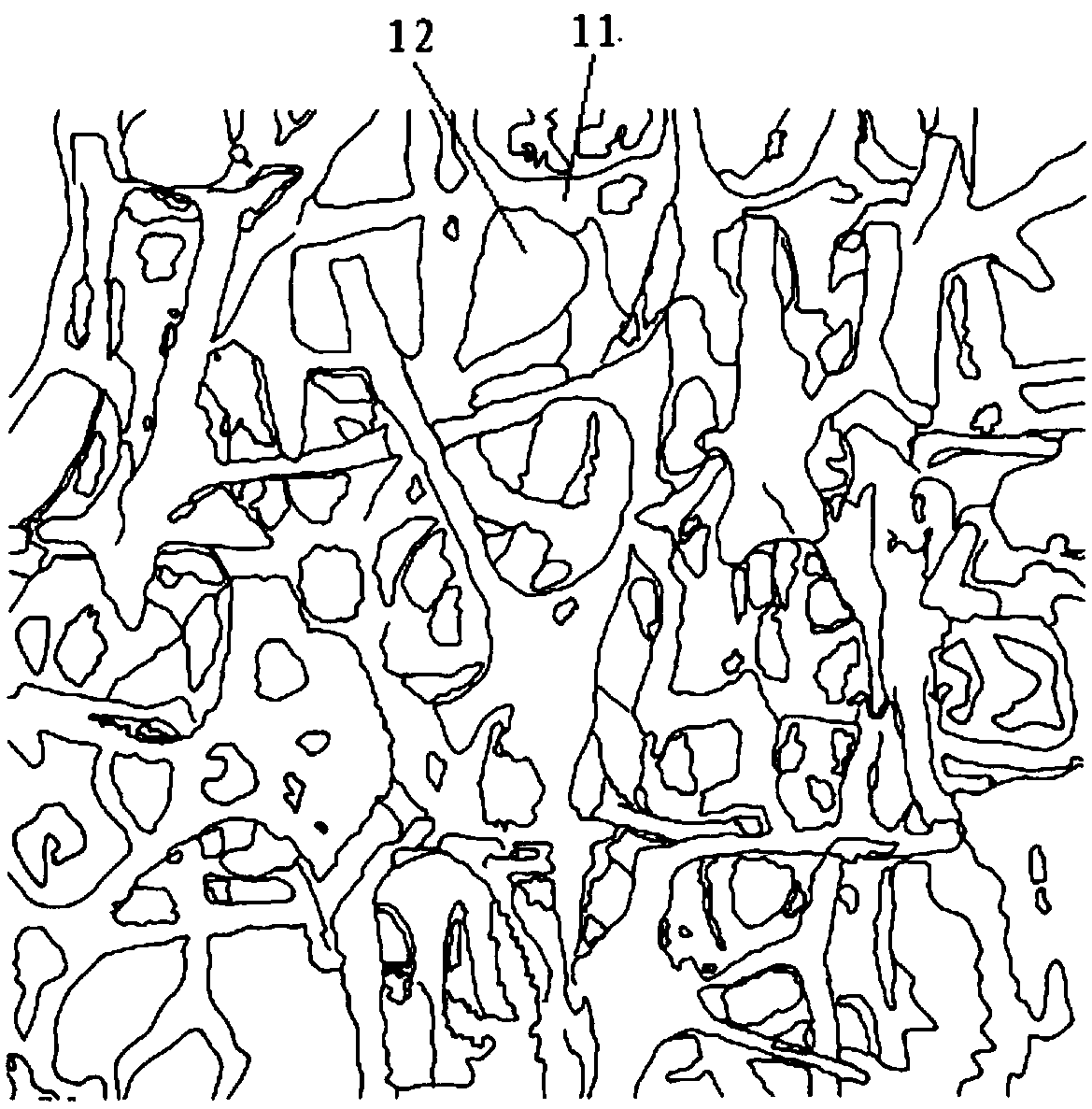

Trabecular bone structure and prosthesis using the structure

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

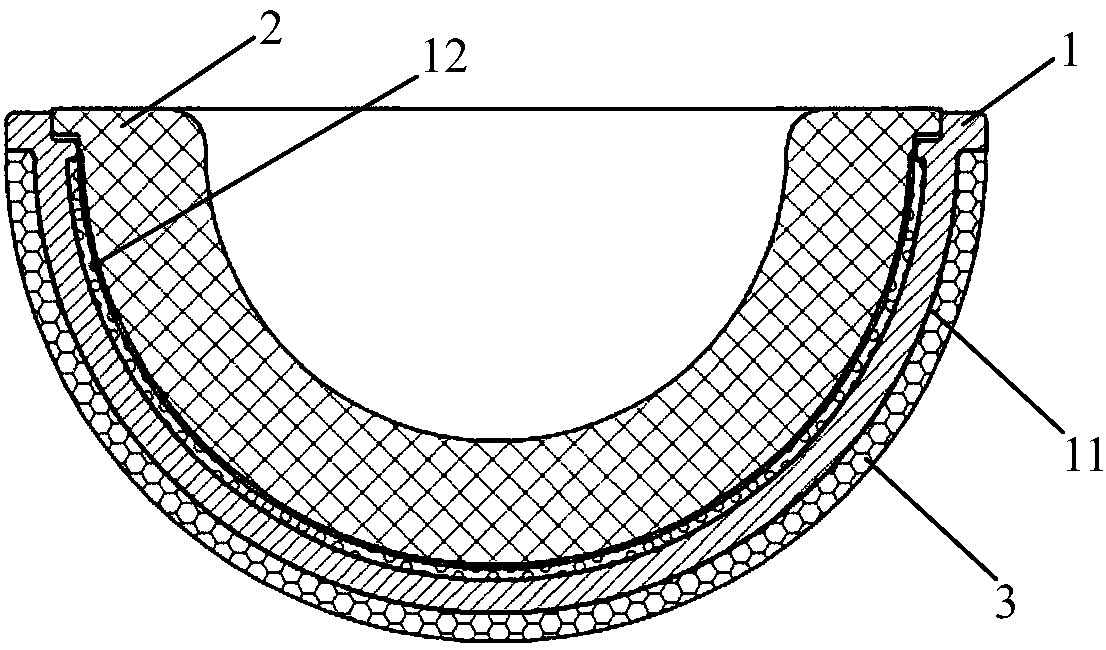

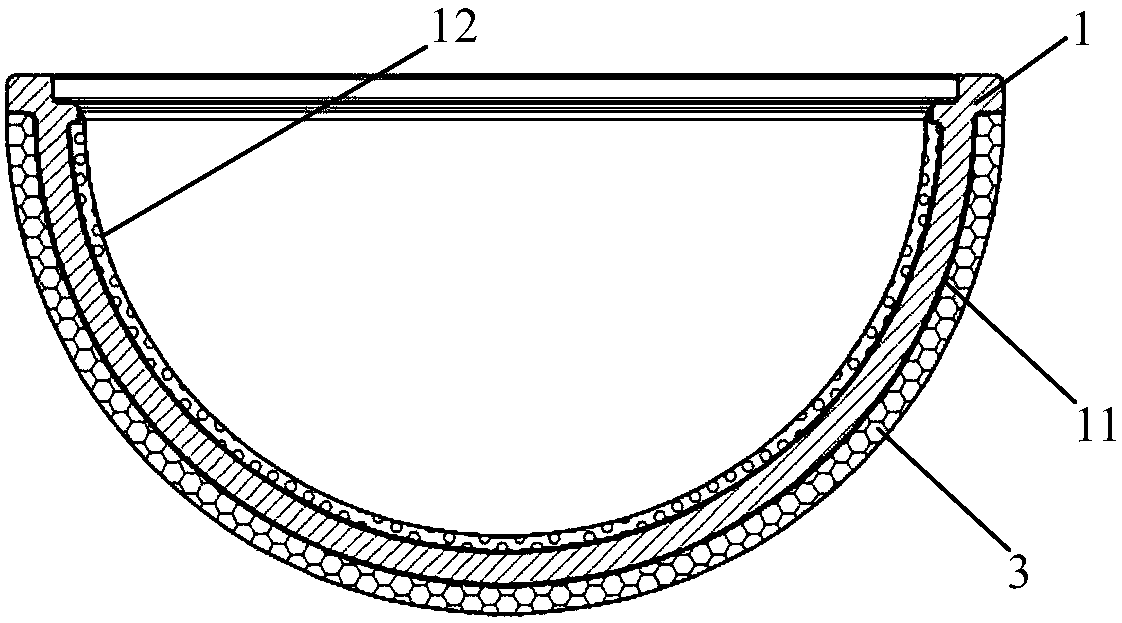

Cup and liner integrated acetabulum component and preparation method thereof

InactiveCN108042243AReduce installation stepsReduced likelihood of wearJoint implantsAcetabular cupsRough surfaceAcetabular liner

The invention provides a cup and liner integrated acetabulum component and a preparation method thereof. The cup and liner integrated acetabulum component comprises an acetabulum cup, an acetabulum liner and a bone trabecula structure. The bone trabecula structure is arranged on the outer surface of the acetabulum cup, the acetabulum cup and the bone trabecula structure are formed integrally, theacetabulum liner is in melt connection with the inner surface of the acetabulum cup, and the inner surface of the acetabulum cup is a rough surface with a microporous structure. Preferably, the porosity of the bone trabecula structure is 50%-65%, the pore diameter of the bone trabecula structure is 300-800micron, the acetabulum cup is a metal acetabulum cup, the bone trabecula structure is a metalbone trabecula structure, and the acetabulum liner is a nonmetal acetabulum liner. The cup and liner integrated acetabulum component is structurally firm and stable, capable of improving post-surgical early-stage fixing effects and long-term stability, safe, simple and convenient to use, long in service life, ingenious in design, simple in structure and convenient and simple in manufacturing.

Owner:上海科太迈迪医疗器械有限公司

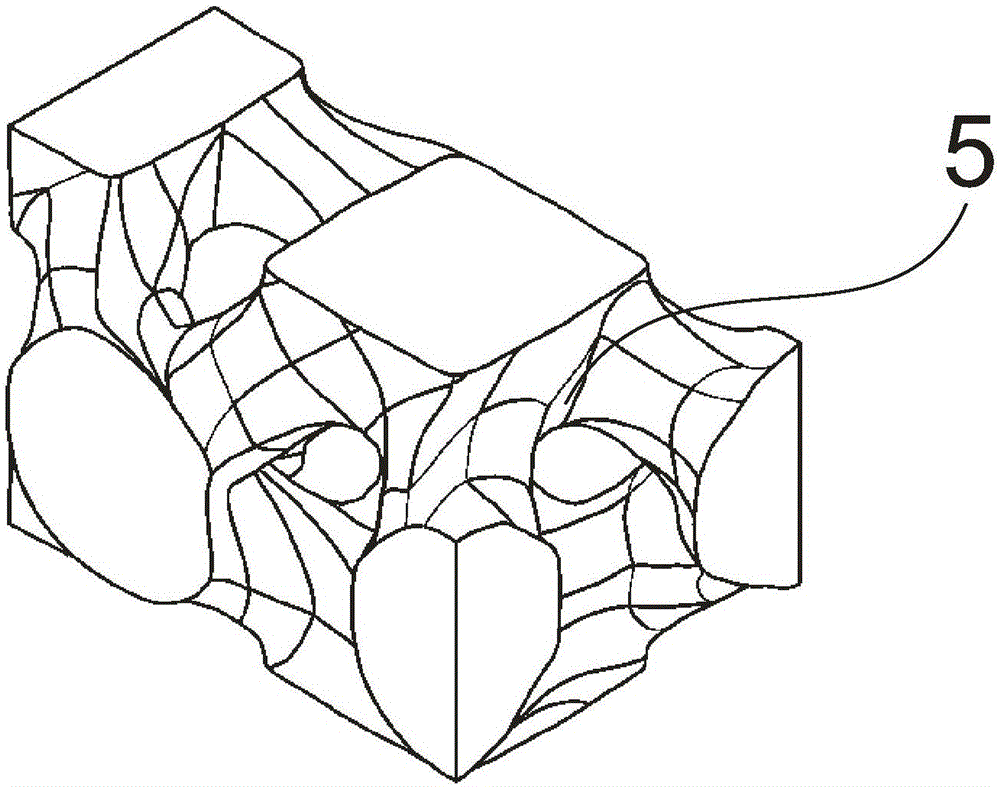

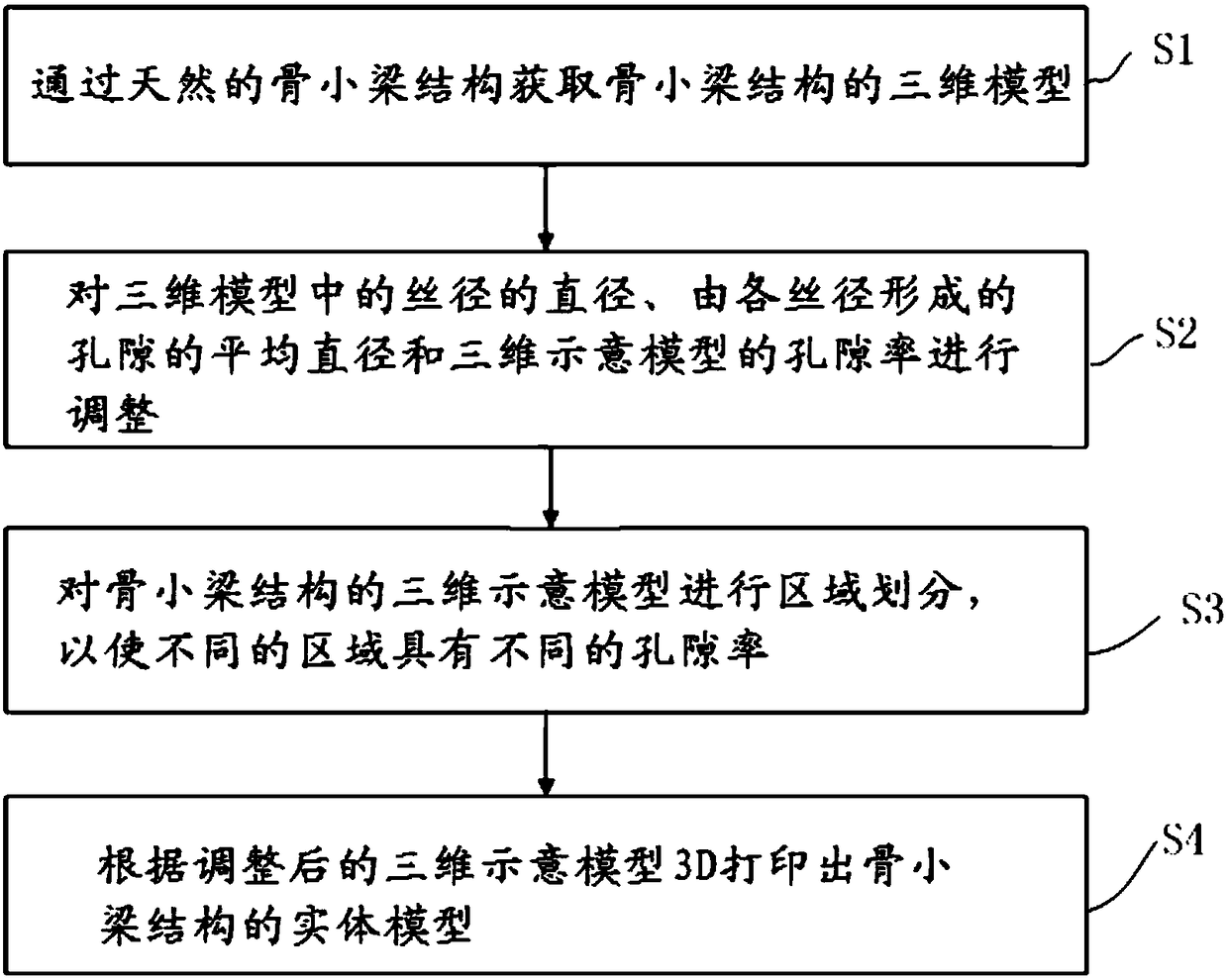

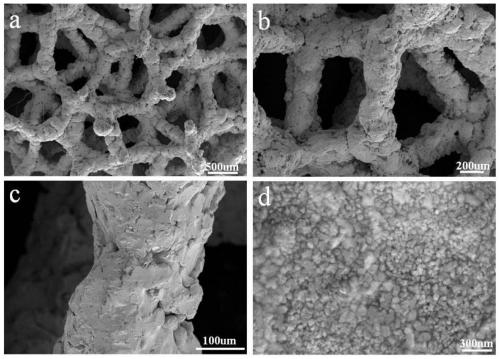

Bionic three-dimensional bone trabecula structure porous tantalum and preparation method thereof

ActiveCN110507850AHigh compressive strengthImprove flexural strengthAdditive manufacturing apparatusIncreasing energy efficiencyPorosityBone Cortex

The invention provides bionic three-dimensional bone trabecula structure porous tantalum and a preparation method thereof, which belong to the technical field of medical orthopedic bionic materials. The bionic three-dimensional bone trabecula structure porous tantalum provided by the invention has a same microstructure as a human bone, is made of metal tantalum, can be better fused with human bonetissue, and promotes bone ingrowth and bone regeneration; besides, by controlling a rod diameter, a hole diameter and the porosity of the porous tantalum of the bionic three-dimensional bone trabecula structure, the compressive strength and the bending strength of the porous tantalum of the bionic three-dimensional bone trabecula structure are higher than those of a normal human bone, the elasticmodulus is between a cancellous bone and a cortical bone, and the stress shielding effect can be effectively reduced. Meanwhile, the preparation method is simple, internal stress remaining in the bionic three-dimensional bone trabecula structure porous tantalum in the printing process is eliminated through annealing, the situation that the structure and mechanical stability of the bionic three-dimensional bone trabecula structure porous tantalum are affected due to subsequent possible stress deformation is prevented, and the final bionic three-dimensional bone trabecula structure porous tantalum has excellent mechanical properties.

Owner:深圳大洲医学科技有限公司

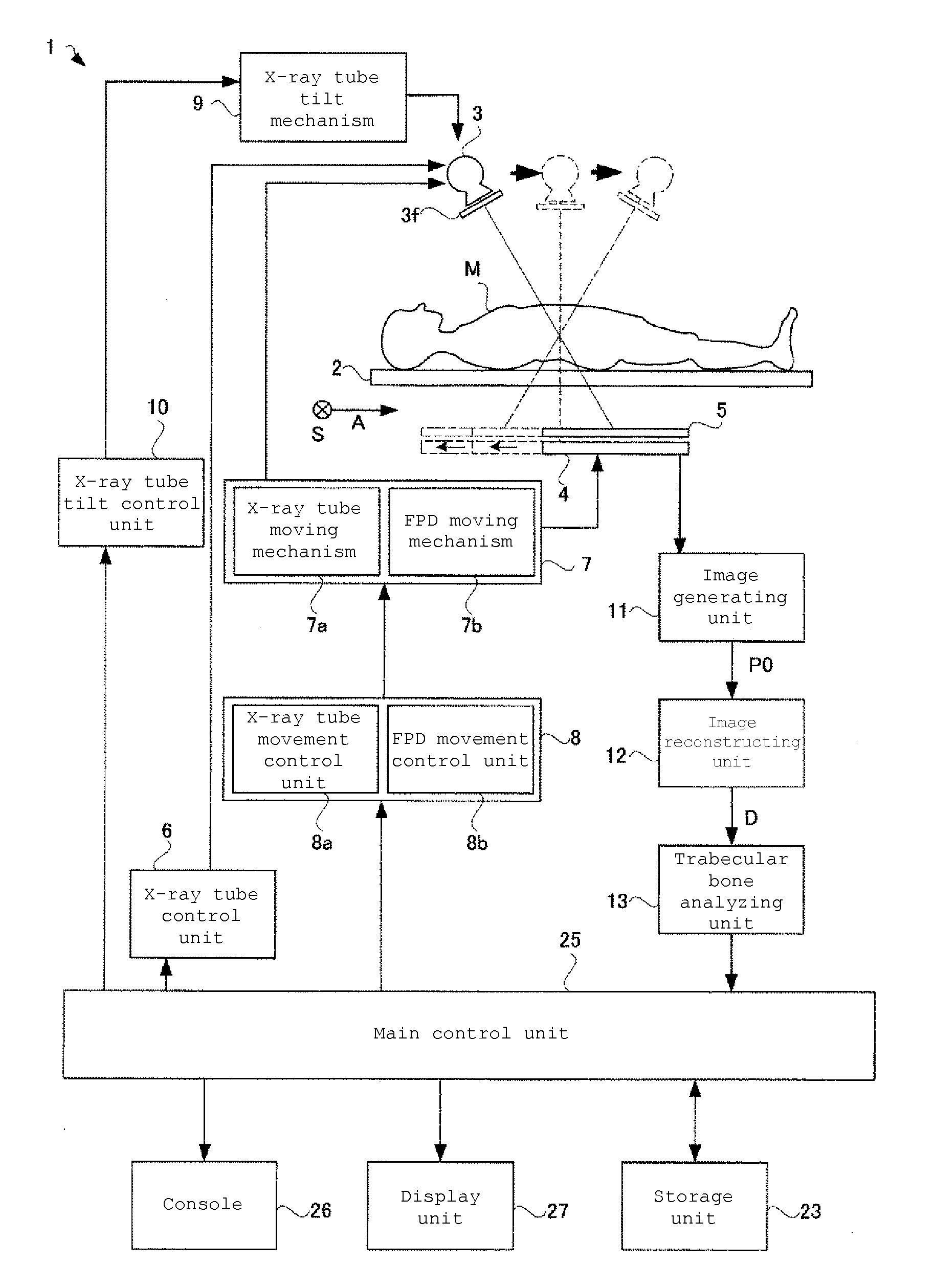

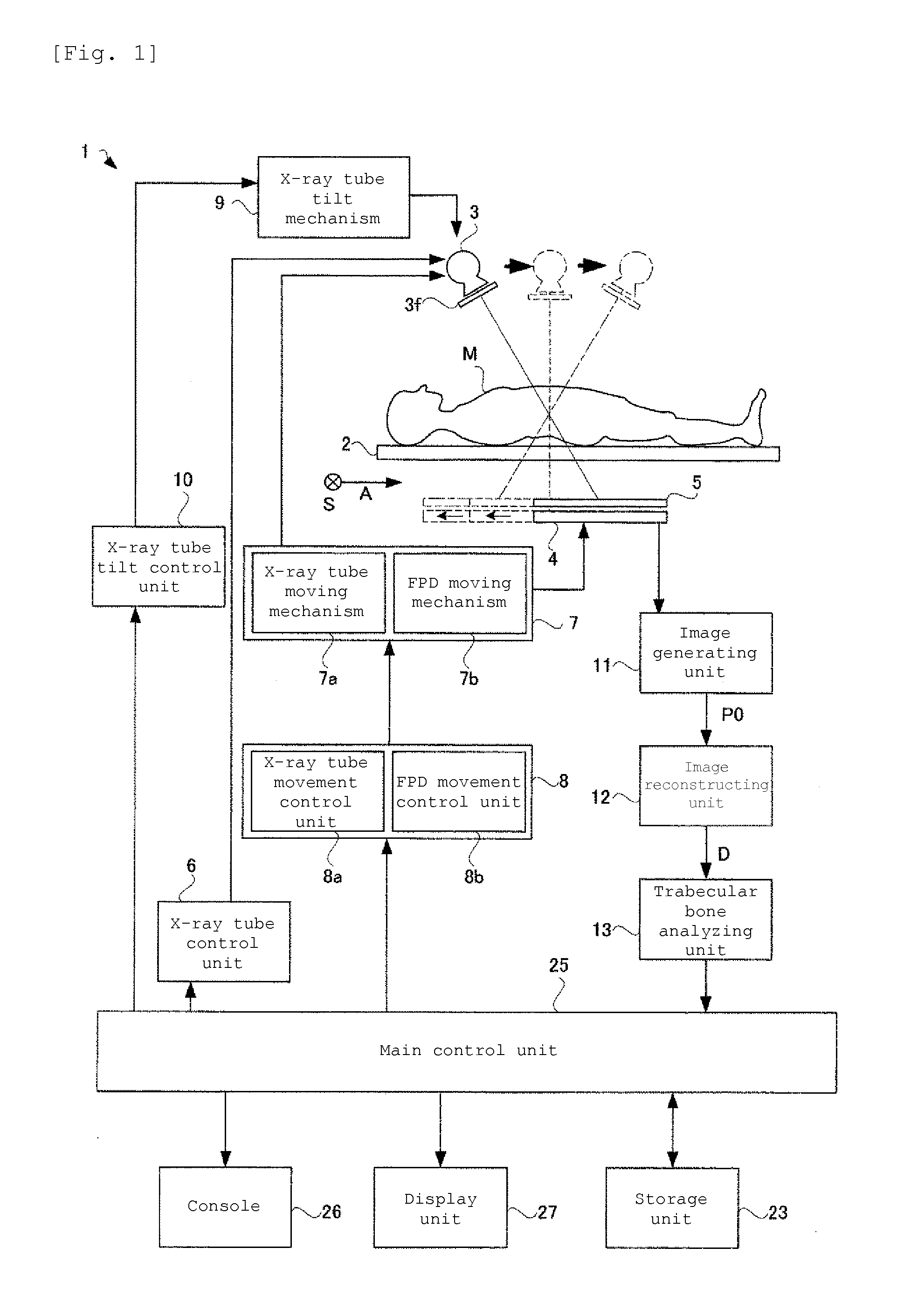

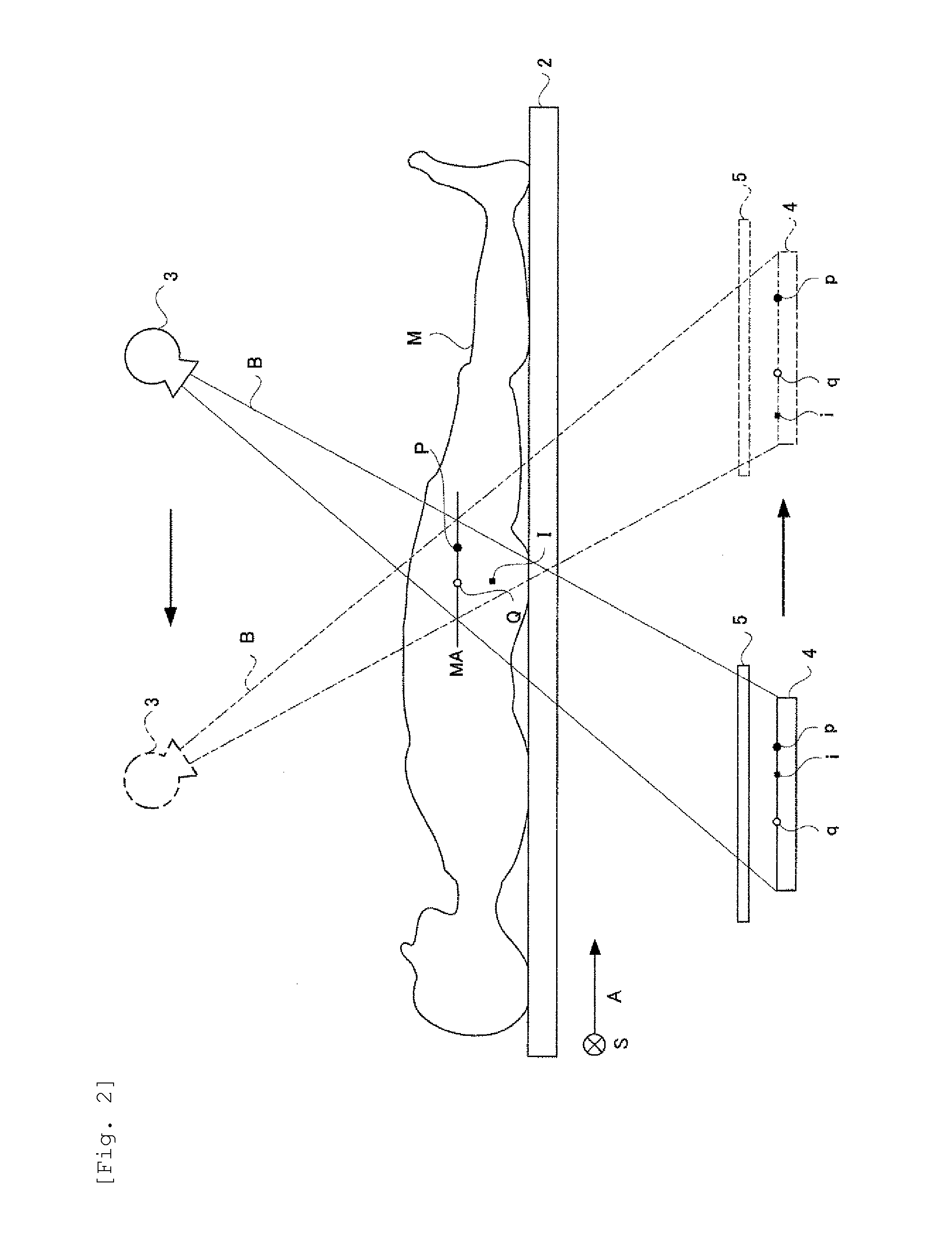

Trabecular bone analyzer

ActiveUS20150221080A1High resolutionQuantitative precisionImage enhancementReconstruction from projectionTrabecular boneTomographic image

Disclosed herein is a trabecular bone analyzer that can quantitatively determine the state of trabecular bone accurately. The trabecular bone analyzer of may perform trabecular bone analysis on a tomographic image D. In the tomographic image D, trabeculae forming a network may appear without overlapping. Therefore, such trabecular bone analysis may more accurately quantify trabecular bone.

Owner:SHIMADZU CORP

Adjustable interbody fixation and fusion device

InactiveCN106264805ALower medical costsWide range of fusionSpinal implantsCoatingsSurgical operationSurgical treatment

The invention provides an adjustable interbody fixation and fusion device and relates to a spinal interbody fusion surgery instrument. The adjustable interbody fixation and fusion device is provided with an upper support platform, a lower support platform, a left sliding support block, a right sliding support block, a rotating shaft, a main rotating gear, an auxiliary rotating gear and a handle, wherein the left sliding support block and the right sliding support block are arranged on the left side and the right side of the upper support platform and the lower support platform respectively; the rotating shaft is arranged between the upper support platform and the lower support platform; the left end and the right end of the rotating shaft are connected with the left sliding support block and the right sliding support block respectively; the main rotating gear is connected with the right end of the rotating shaft; the auxiliary rotating gear is meshed with the main rotating gear; the handle is connected with the main rotating gear. With the adoption of the adjustable interbody fixation and fusion device, surgical operation can be simplified, surgical time can be shortened, the surgical treatment effect can be improved, and the medical expenses of a patient can be reduced; the height of the device can be adjusted according to the interbody space height, the fusion range of a kidney-shaped fusion surface is wider, the fusion effect of a bone trabecula structure is better, the surgical operation is more simplified, and the long-term effect of fixation and fusion is better.

Owner:张衣北

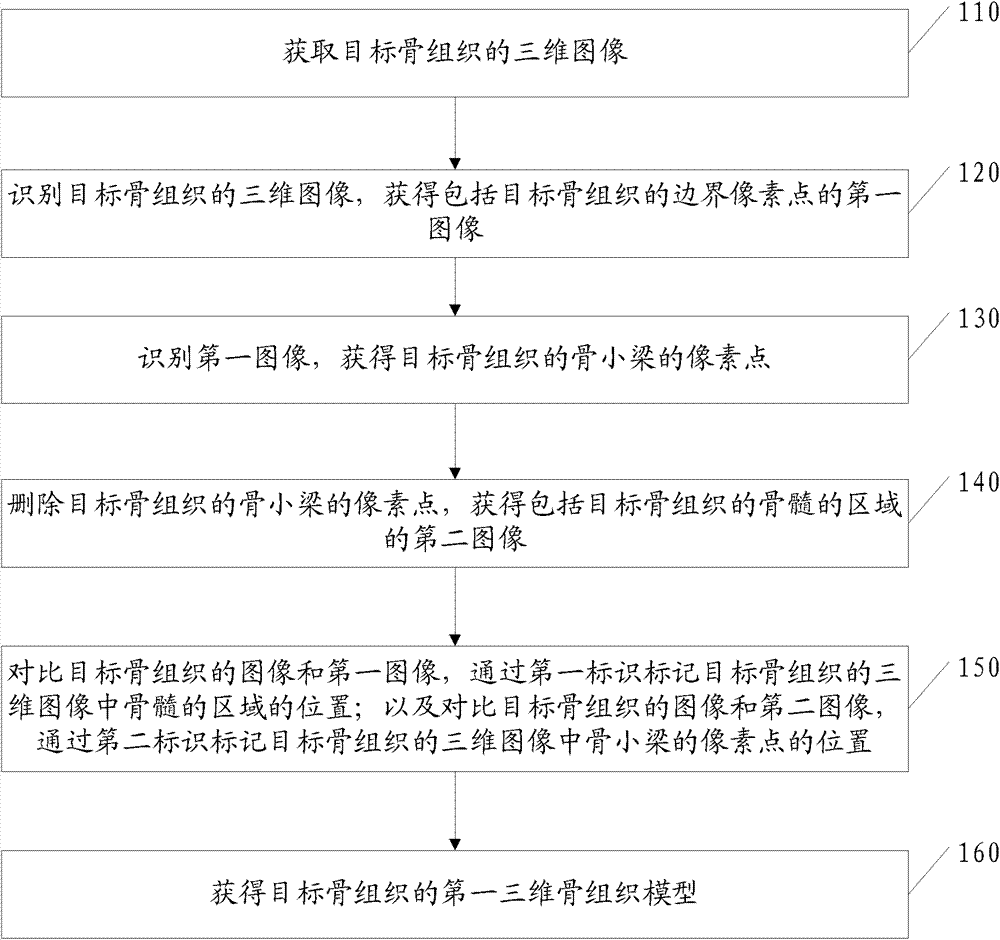

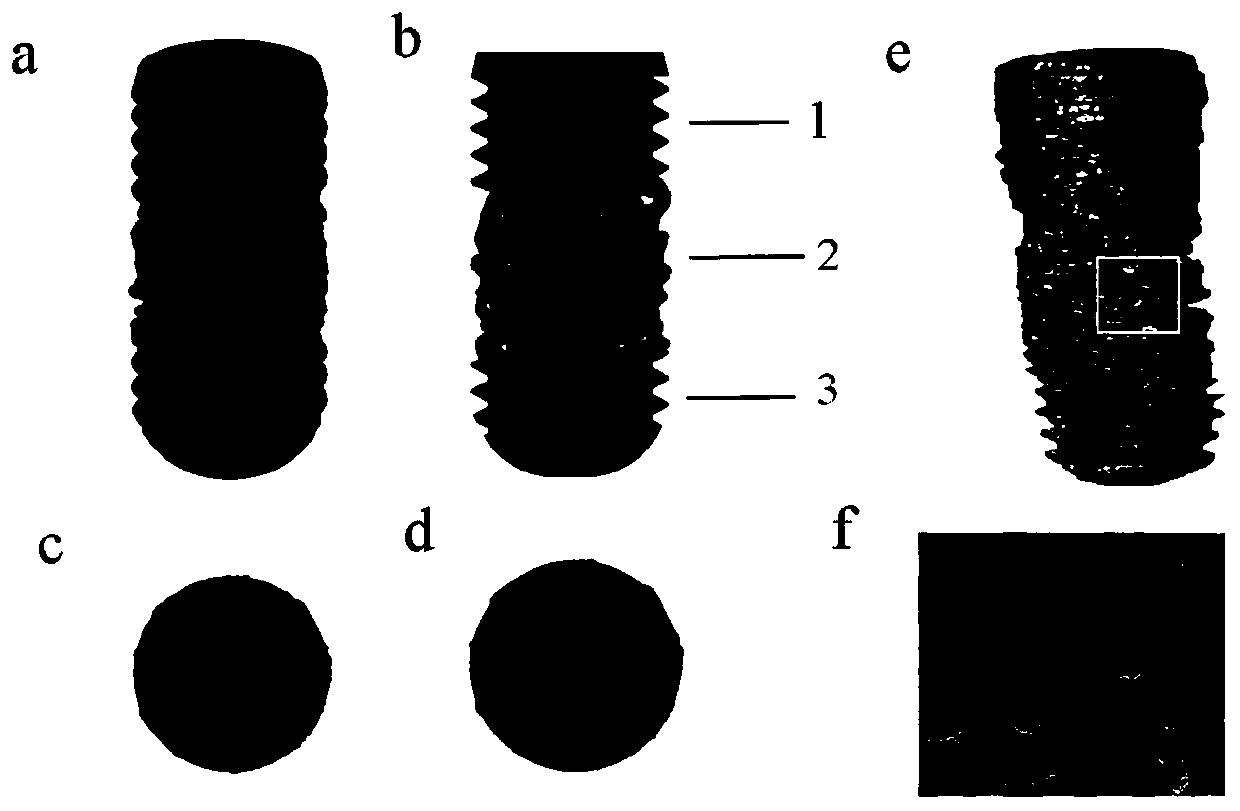

Three-dimensional bone tissue model building method and equipment

The invention discloses a three-dimensional bone tissue model building method. The method comprises the steps of obtaining the first image of a region enclosed by the boundary pixels and boundary pixels of a target bone tissue by identifying the three-dimensional image of the target bone tissue; identifying the first image; deleting the pixels of bone trabecula of the target bone tissue to obtain a second image of the marrow region of the target bone tissue, and comparing the image of the target bone tissue and the first image; identifying the position of the marrow region of the target bone tissue in the three-dimensional image of the target bone tissue by a first identifier; comparing the image of the target bone tissue and the second image; identifying the positions of the pixels of the bone trabecula of the target bone tissue in the three-dimensional image of the bone tissue by the second identifier so as to obtain a first three-dimensional bone tissue model of the target bone tissue, thereby obtaining the forms of the real bone trabecula and the marrow, and obtaining the three-dimensional bone tissue model which realistically displays the inner form of the target bone tissue.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

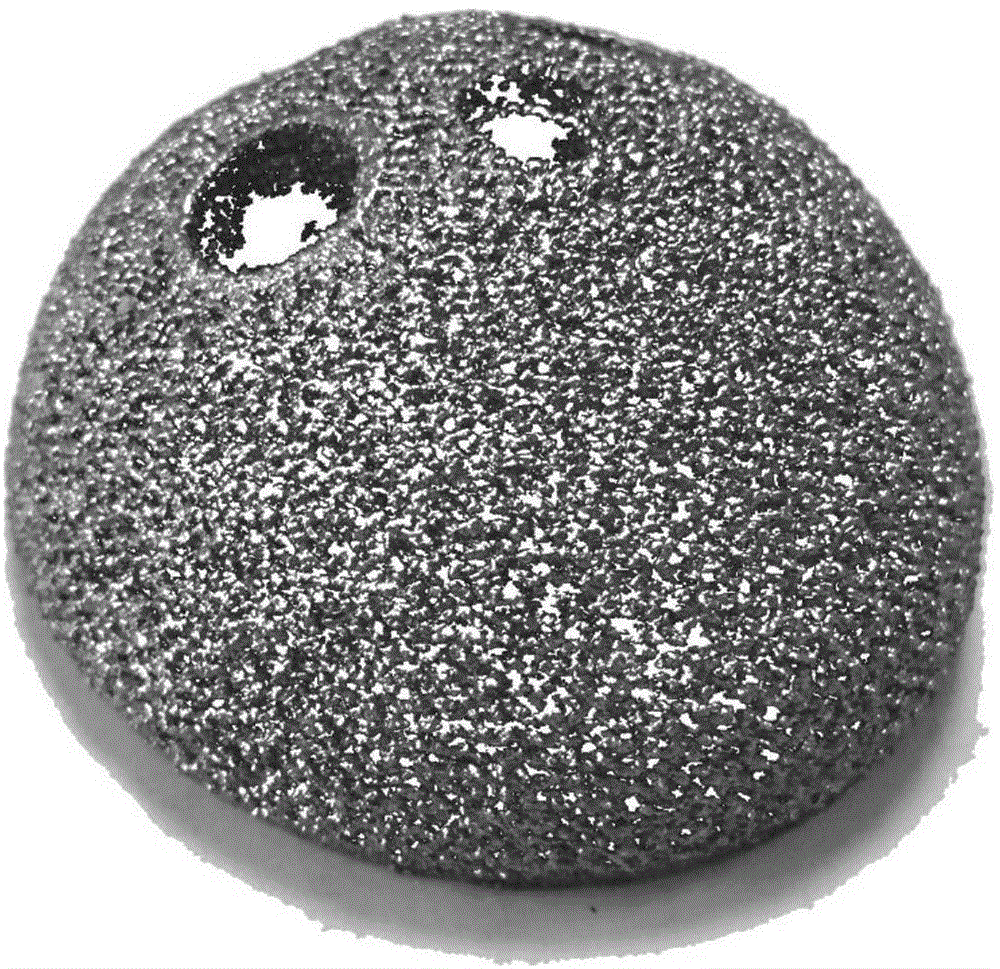

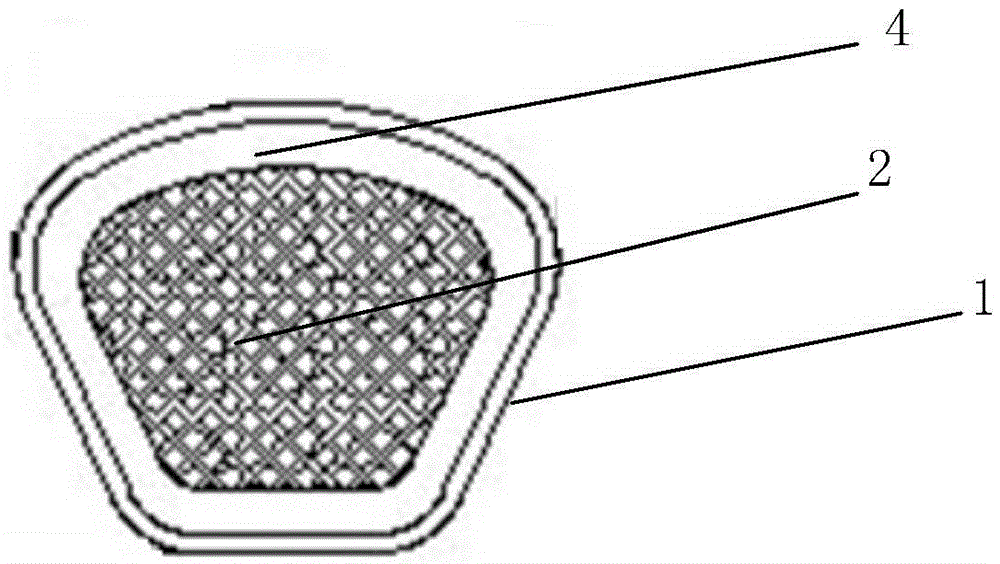

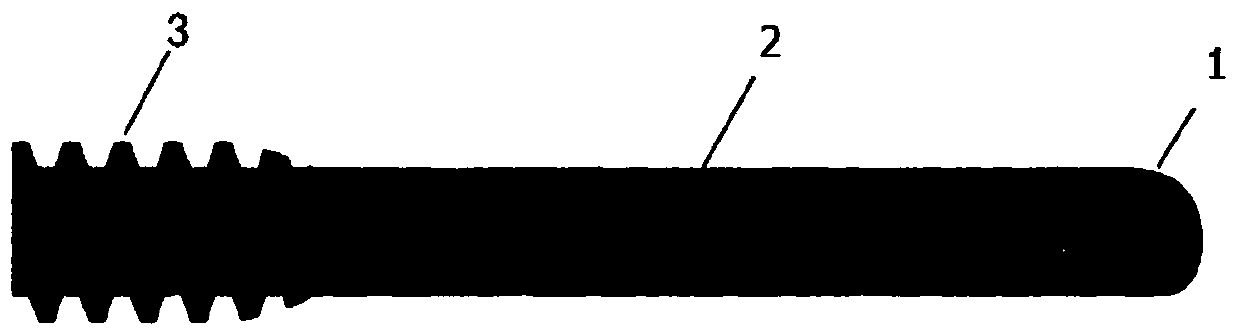

Bone trabecula porous tantalum dental implant and preparation method thereof

PendingCN111494035AHigh porosityHigh strengthDental implantsAdditive manufacturing apparatusPorous tantalumDentistry

The invention relates to the technical field of biomedical metal materials and oral implantation medical instruments, and provides a bone trabecula porous tantalum dental implant and a preparation method thereof. The bone trabecula porous tantalum dental implant provided by the invention has a cylindrical structure and sequentially comprises a top functional area, a middle functional area and a bottom functional area from top to bottom. The top functional area is of a compact structure, the middle functional area has a bionic bone trabecula porous structure, and the bottom functional area hasa compact structure. The bone trabecula porous tantalum dental implant is integrally prepared by taking pure tantalum or medical tantalum alloy powder as a raw material through an additive manufacturing technology. The bone trabecula porous tantalum dental implant provided by the invention is high in friction force, close to human bone in strength and modulus, excellent in bone ingrowth effect, high in implantation stability and long in service life, is of an integrated structure, and has no risk of delamination and separation during implantation.

Owner:深圳大洲医学科技有限公司

Talus prosthesis

ActiveCN108210130AEasy to integrateEasy to replaceAnkle jointsJoint implantsMedial malleolusCalcaneus

The invention relates to a talus prosthesis which comprises a complete talus prosthesis body. The complete talus prosthesis body comprises a nonmetallic material part on the upper side and a metal material part on the lower side. The nonmetallic material part and the metal material part can be combined and assembled. The nonmetallic material part comprises a trochoid articular facet and a medial malleolus articular facet. The metal material part comprises a subtalar articular facet. The nonmetallic material part or the metal material part comprises a talonavicular articular facet. Four to fivefastening nail channels are arranged on the metal material part. The subtalar articular facet and / or the talonavicular articular facet is / are of a porous bone trabecula structure or is / are provided with hydroxyapatite coatings. Due to the detachable nonmetallic material part and the detachable metal material part, replacement during revision is facilitated; the porous bone trabecula structure orthe hydroxyapatite coatings are adopted for the areas adjacent to bones, and bone fusion can be promoted; the gap outside a talus bone and a calcaneal bone is filled with a protruding part A, and stability is improved.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

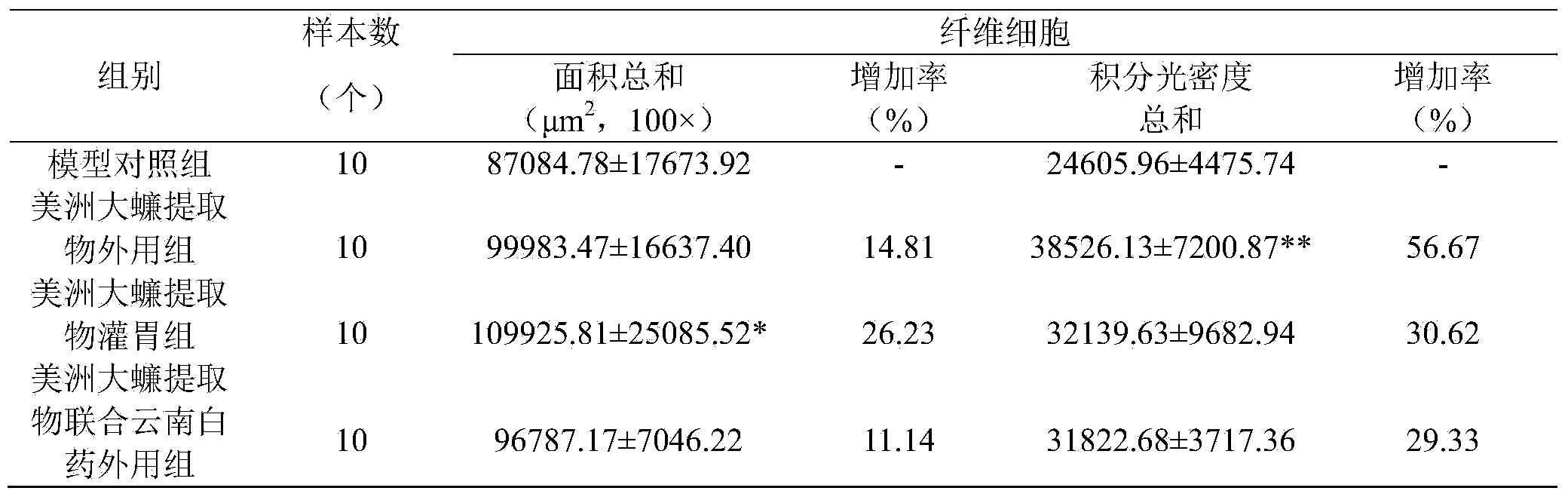

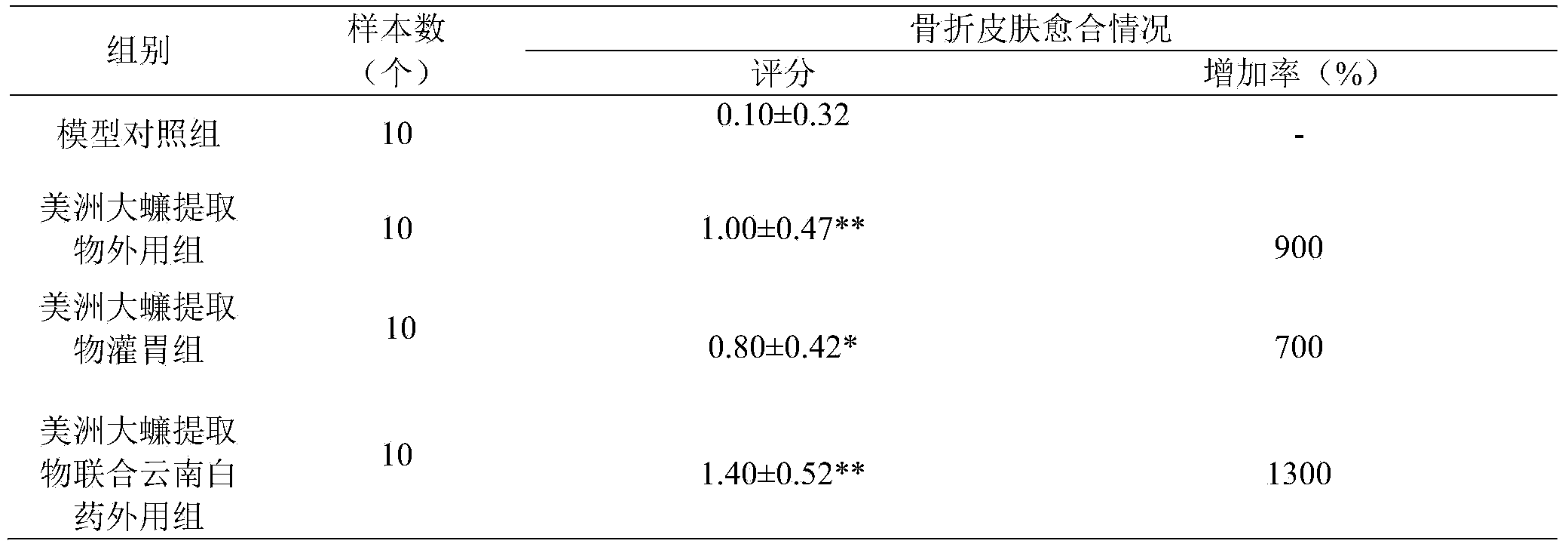

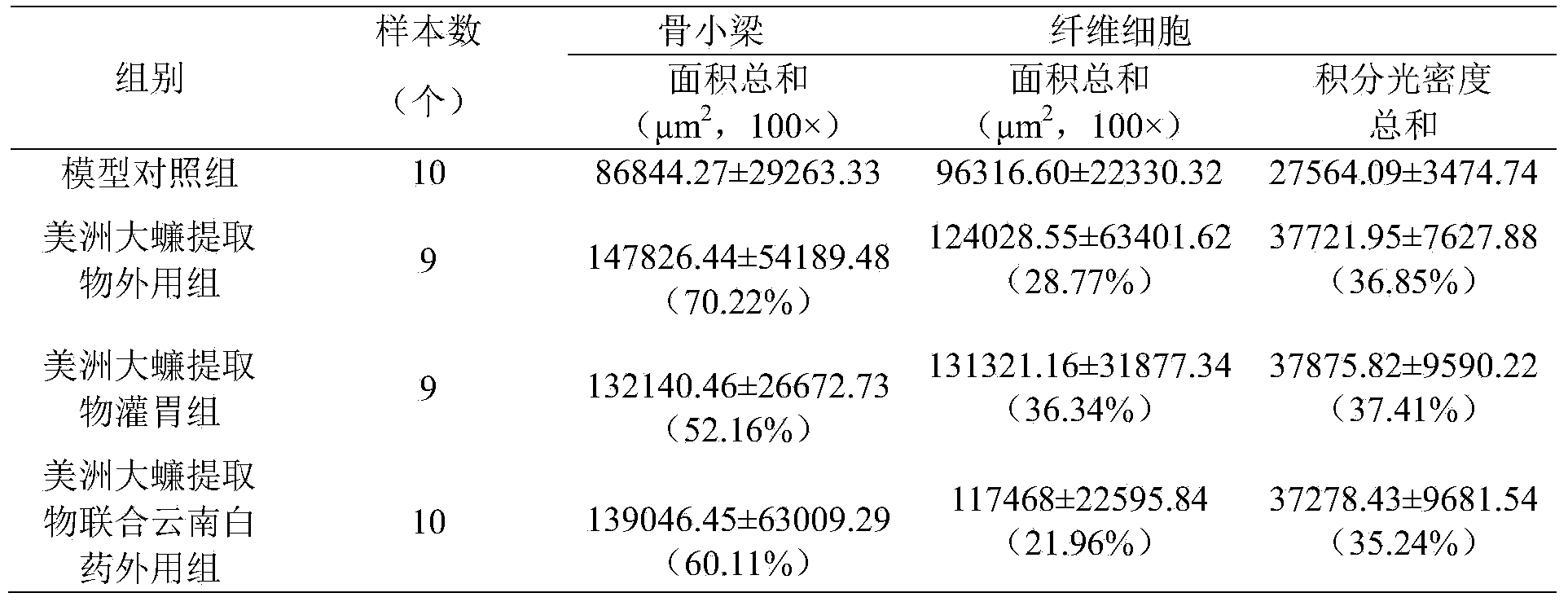

Novel application of periplaneta americana extractive

InactiveCN104306404APromote generationPromote healingAnthropod material medical ingredientsSkeletal disorderMedicineOsteoblast

The invention discloses a novel application of a periplaneta americana extractive and in particular discloses a novel application of the periplaneta americana extractive in preparation of a medicament for treating bone fracture. The periplaneta americana extractive is capable of promoting increase of the amount and substance content of callus fibrocyte, area of bone trabecula, osteoblast and osteocyte and facilitating decrease of osteoclast, thus promoting generation of callus, and is also capable of promoting healing of skins at fracture parts. The medicament prepared by singly using periplaneta americana or matching the periplaneta americana and other medicaments is used for treating the bone fracture, is capable of promoting the generation of the callus, promoting the healing of the skins at the fracture parts and shortening treating time, is low in cost, is remarkable in curative effect and is a new choice for clinically treating the bone fracture.

Owner:耿福能

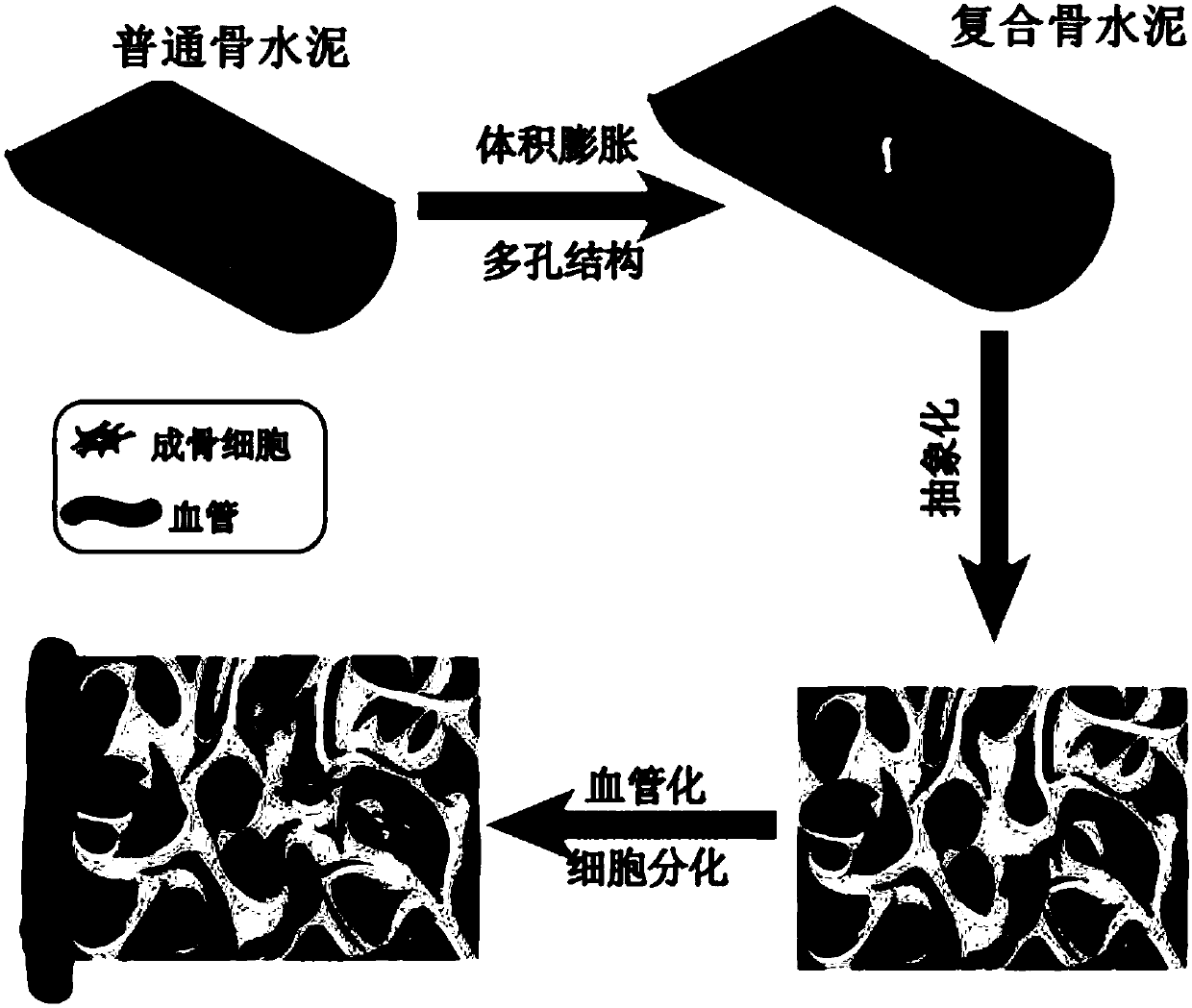

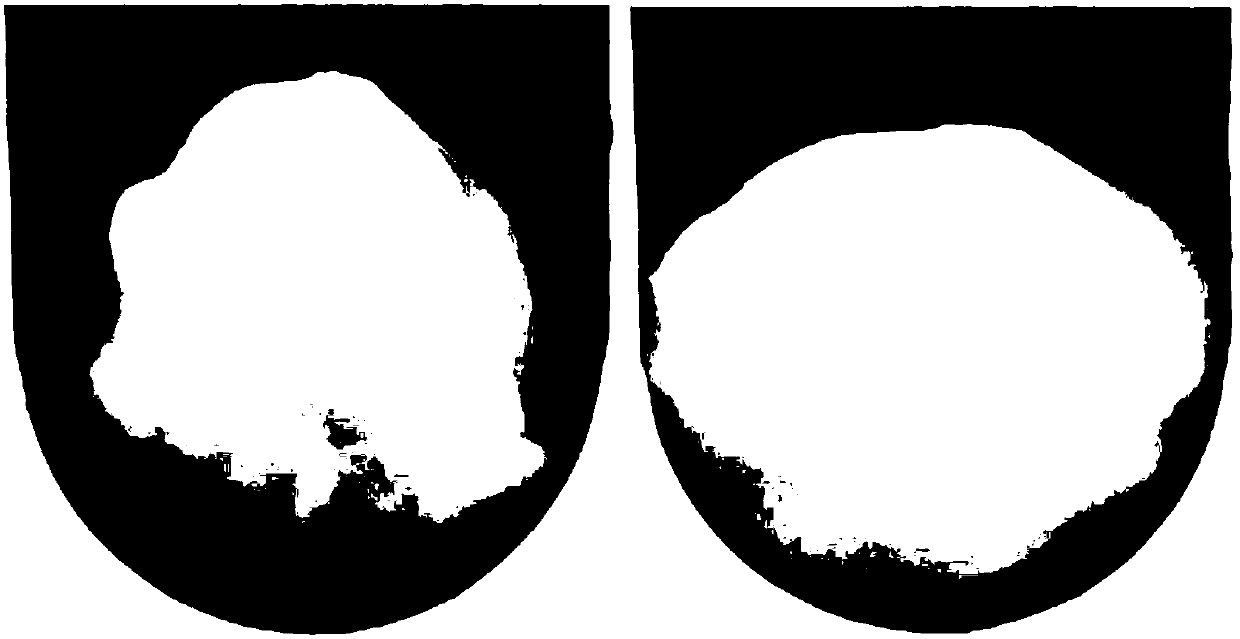

Injectable expanded composite bone cement of bone-imitating trabecula structure and preparation method of injectable expanded composite bone cement

PendingCN108187144AReduce dosageSmall heat releaseTissue regenerationProsthesisCondensation processBiocompatibility Testing

The invention provides injectable expanded composite bone cement of a bone-imitating trabecula structure and a preparation method of the injectable expanded composite bone cement. The composite bone cement is prepared from a powder material, a curing solution and an expanding material, wherein the powder material and the expanding material are uniformly mixed according to a certain ratio; the curing solution is added and is uniformly stirred to obtain composite bone cement slurry; the composite bone cement slurry is injected into a mold and is cured to obtain a composite bone cement cured body. The bone cement prepared by the method has good injection performance; in a condensation process, remarkable volume expansion can be generated; finally, a porous structure similar with a bone trabecula is formed in the bone cement; the injectable expanded composite bone cement has good biocompatibility, the growth of cells and tissues is facilitated and the cells have remarkable activity on theinjectable expanded composite bone cement. The method provided by the invention has a simple and convenient process and can be widely applied to field of bone repairing.

Owner:UNIV OF SCI & TECH BEIJING

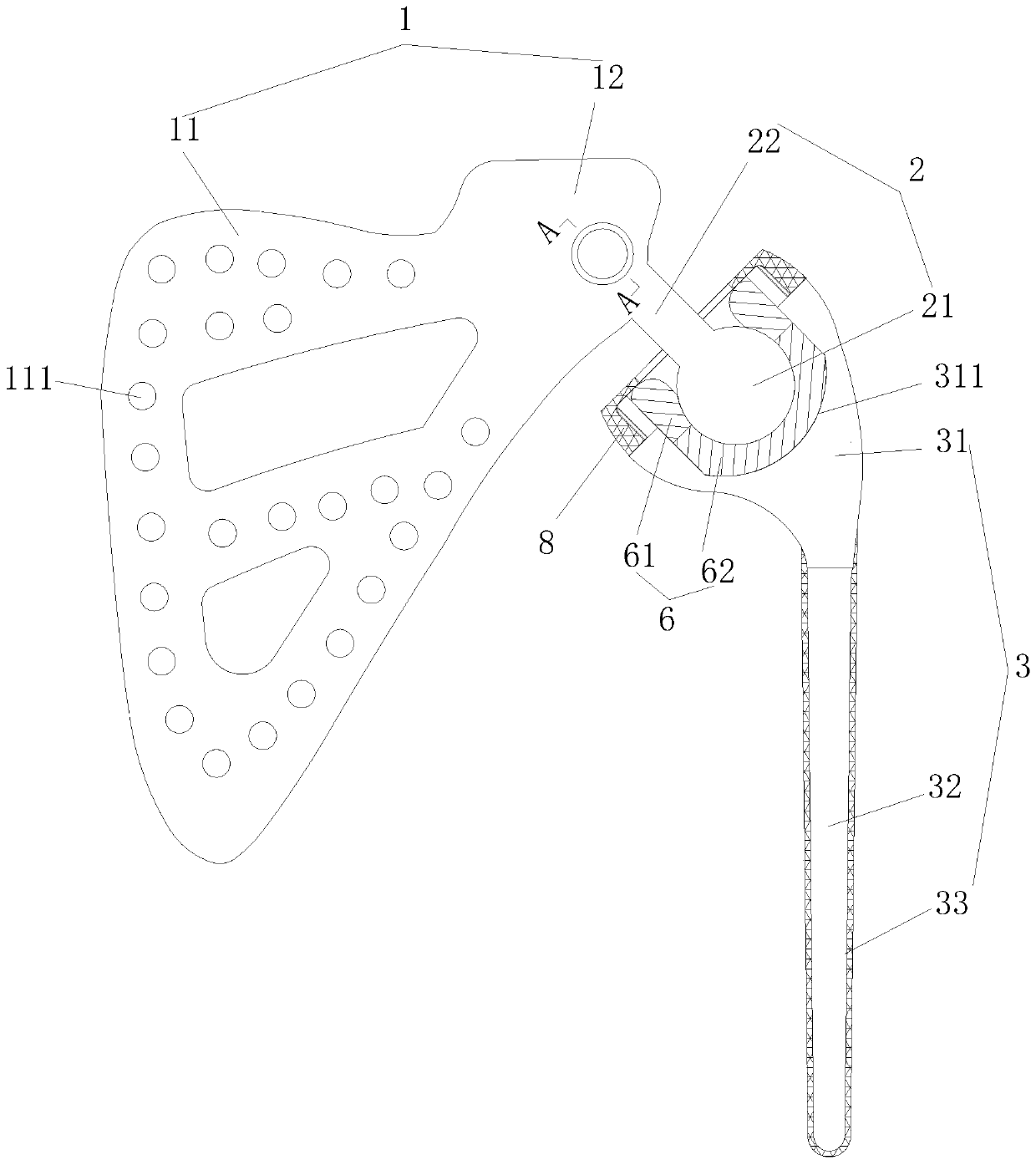

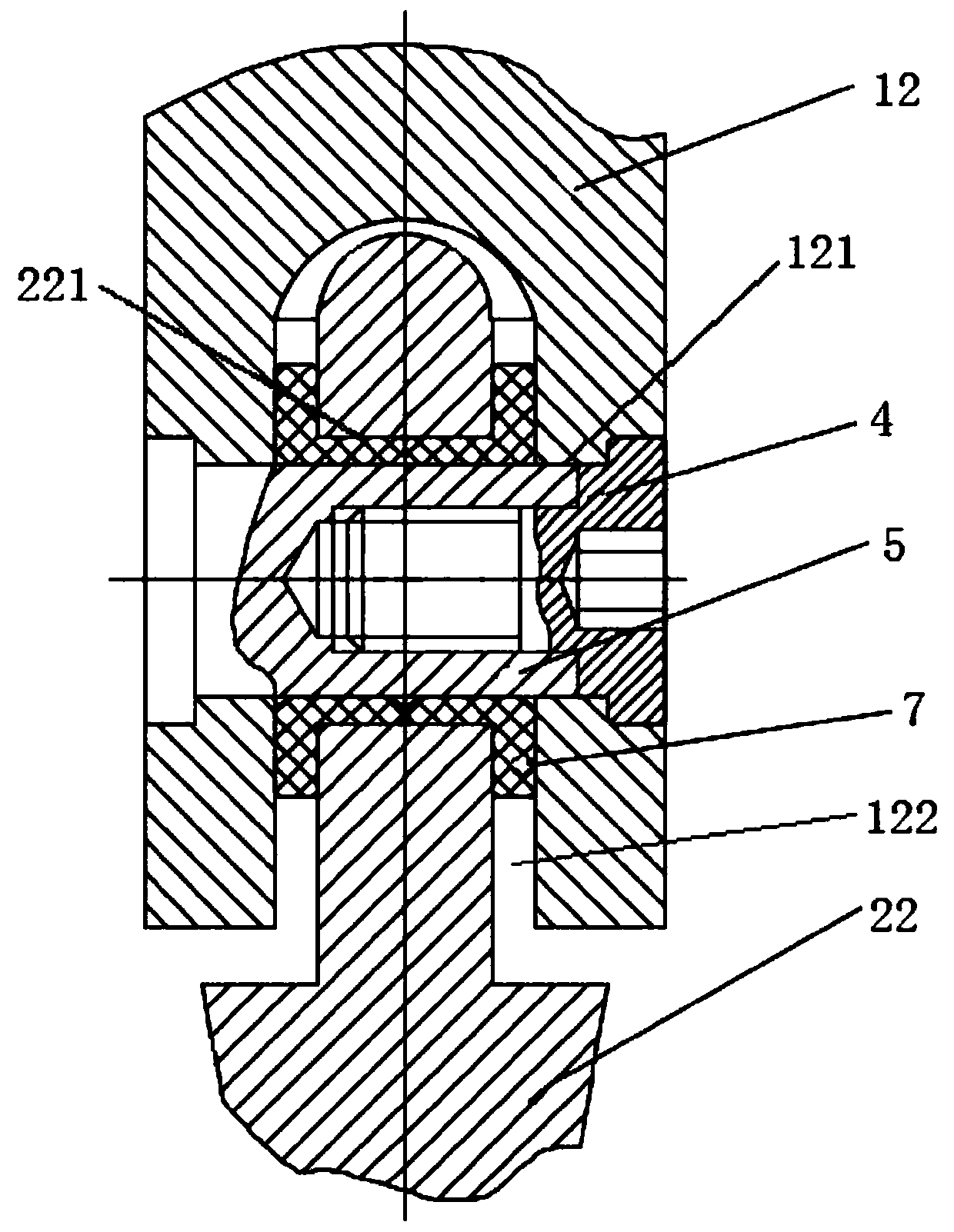

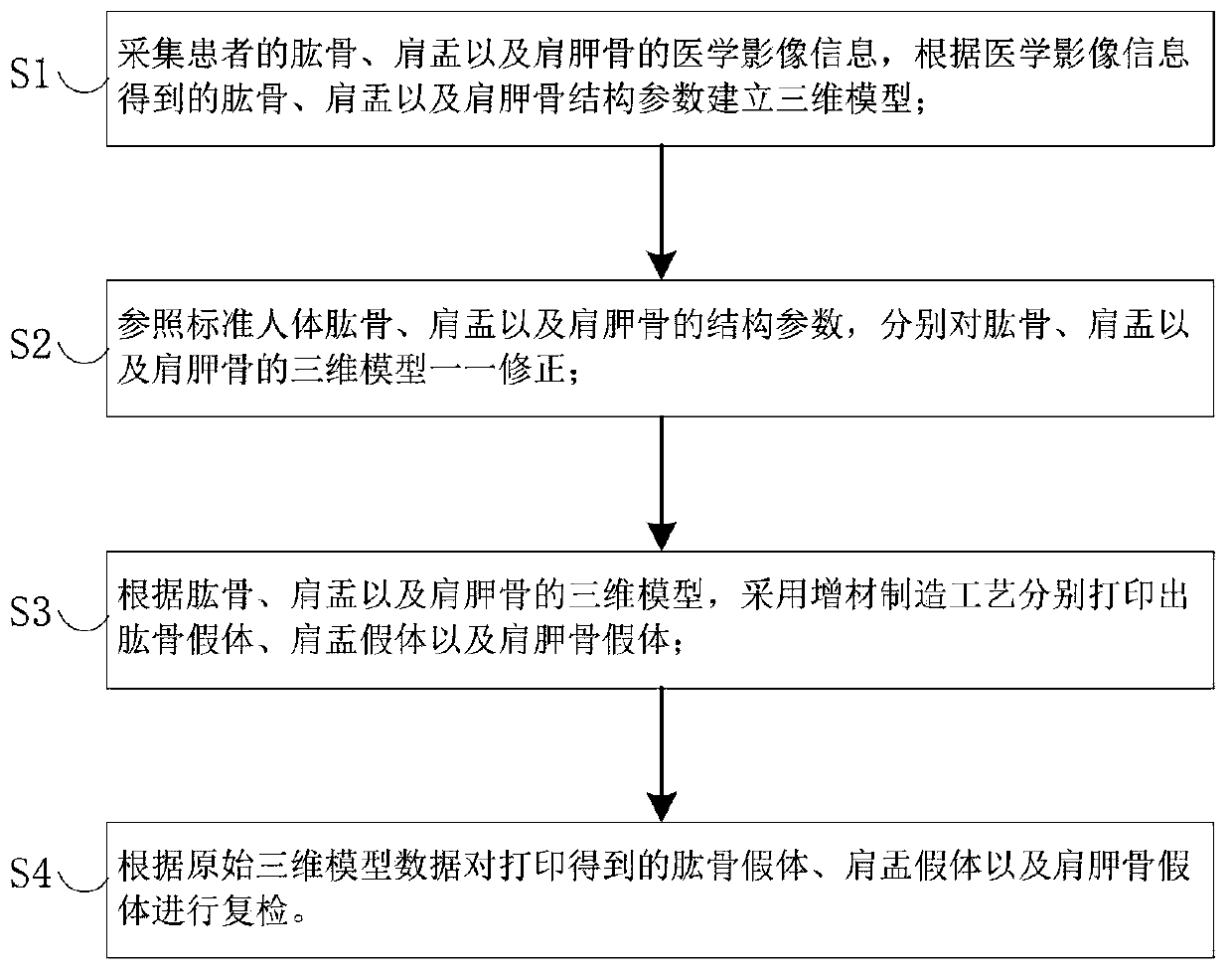

Assembly type shoulder joint prosthesis and manufacturing method thereof

ActiveCN111374805ASolve the errorAvoid printing errorsJoint implantsTomographyBone humerusBone cement

The invention provides an assembly type shoulder joint prosthesis and a manufacturing method thereof. The assembly type shoulder joint prosthesis comprises a scapula prosthesis, a glenoid cavity prosthesis and a humerus prosthesis, wherein the free end of a glenoid cavity supporting rod of the glenoid cavity prosthesis is in movable pivot connection with a glenoid cavity part of the scapula prosthesis; a glenoid cavity bone inner sleeve of the glenoid cavity prosthesis is arranged in a humeral head hinging groove of the humerus prosthesis; and a bone trabecula structure is arranged on the outer wall of a humerus handle in a coating manner. Through the adoption of the assembly type shoulder joint prosthesis disclosed by the invention, a set of the scapula prosthesis, the glenoid cavity prosthesis and the humerus prosthesis which are assembled in a cooperating manner and are mutually connected and in cooperation is provided, so that the prosthetic replacement requirements of a patient ofwhich the humerus, the glenoid cavity and the scapula are damaged can be met, and relative moving relationship between the scapula and the glenoid cavity of the human body is also practically simulated; and the bone trabecula structure is arranged on the outer wall of the humerus handle in a coating manner, so that the human organism can be quickly and firmly adhered to the prosthesis, and the problem that prosthesis loosening is easy to generate through bone cement, and during polymerization of the bone cement monomer, a large amount of heat is released, and periphery tissue damages are generated are solved.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

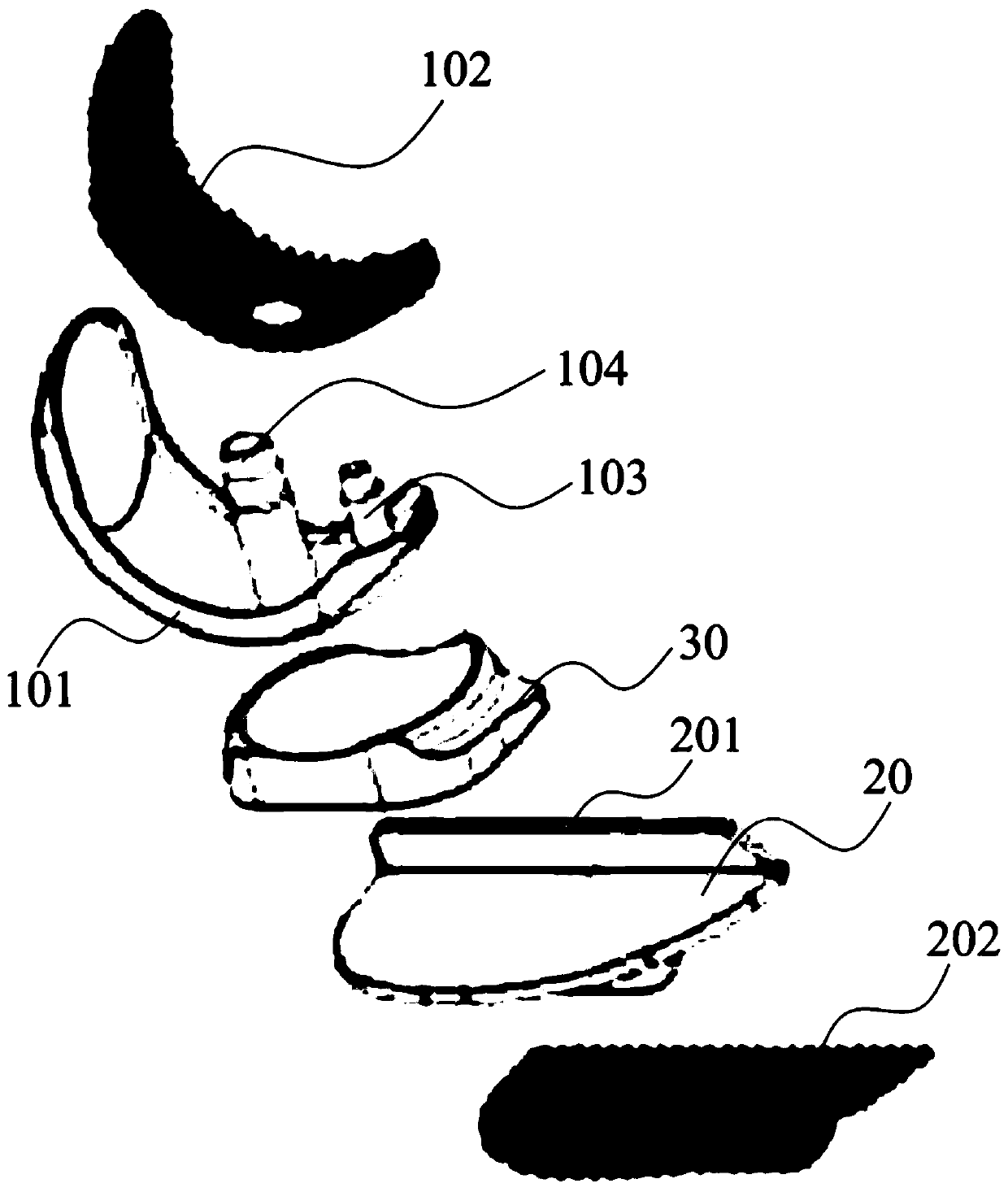

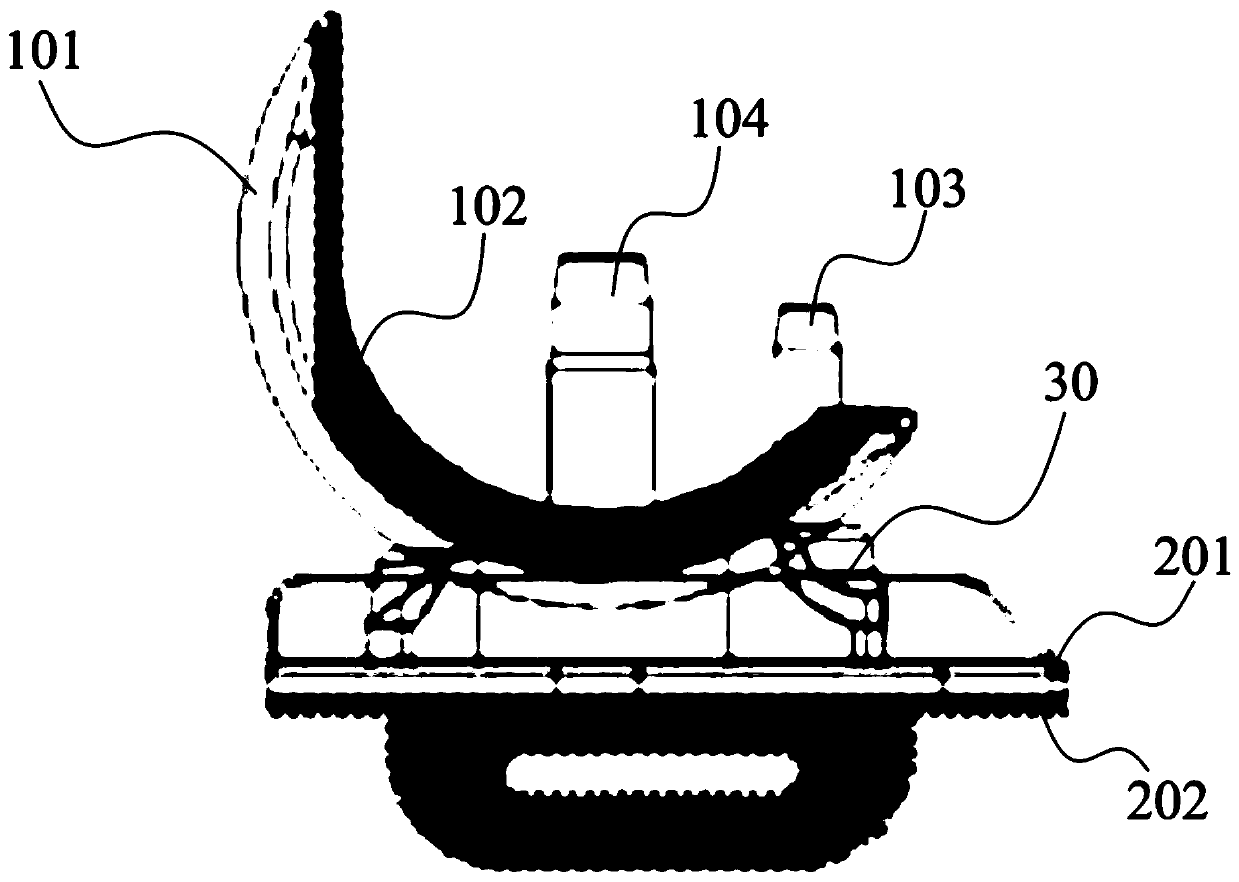

Single-compartment knee joint prosthesis and manufacturing method thereof

PendingCN111345921AGuaranteed to grow inAvoid coating peelingJoint implantsKnee jointsTibial boneKnee arthrodesis prosthesis

The invention relates to a single-compartment knee joint prosthesis. The single-compartment knee joint prosthesis comprises: a femoral condyle, wherein the inner side, facing the far end of the femoral head, of the femoral condyle is provided with a femoral condyle bone trabecula structure which is integrally formed through 3D printing fusion, and the inner surface of the femoral condyle bone trabecula structure is designed to be a spherical outline suitable for being in close press fit with the femur subjected to grinding treatment; a tibial plateau, wherein the lower side, facing the tibialosteotomy end, of the tibial plateau is provided with a tibial plateau bone trabecula structure which is integrally formed through 3D printing fusion; and a gasket, wherein the upper surface of the gasket is concave and fits the spherical outer side surface of the femoral condyle, and the lower surface of the gasket is a plane and fits the upper plane of the tibial plateau. The femoral condyle bone trabecula structure and the tibial plateau bone trabecula structure are formed by space-filling polyhedral unit cell structure in a topological mode, and have wire diameters or hole diameters whichare limited and randomized on the basis of set wire diameter or hole diameter parameters.

Owner:JIASITE HUAJIAN MEDICAL EQUIP (TIANJIN) CO LTD

3D printing self-locking type anatomic artificial centrum and making process

PendingCN108175544AControl angle sizeEasy to integrateAdditive manufacturing apparatusSpinal implantsCarrying capacityHoneycomb

The invention discloses a 3D printing self-locking type anatomic artificial centrum. It includes the upper centrum and the lower centrum. The upper and lower centrums are connected with a groove and abulge. The surface of the upper and lower centrums is set with honeycomb bone trabecular structure. The contact surface of the upper and lower centrums has a physiological radian associated with thespine in contact with the spine. The structure of the bone trabecula is irregular three-dimensional mesh. The artificial centrum provided by the invention is the combination of two pieces of separate3D printing products without slip phenomenon, and the combination use is more convenient. The length can be processed based on the height of the patient's pathological changes and the contact positionof the centrum, and can control the size of the angle between the centrums, reduce the incidence of settlement, enhance the stability, and restore the back of the spine. Through honeycomb micro porestructure, promoting bone fusion, providing the optimal spinal physiological mechanism stability and carrying capacity, and finally achieving bone fusion.

Owner:北京中安泰华科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com