Injectable expanded composite bone cement of bone-imitating trabecula structure and preparation method of injectable expanded composite bone cement

A technology of trabecular structure and bone cement, applied in medical science, tissue regeneration, prosthesis, etc., can solve the problems of heat generation, high elastic modulus, and difficult for cells to grow in.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

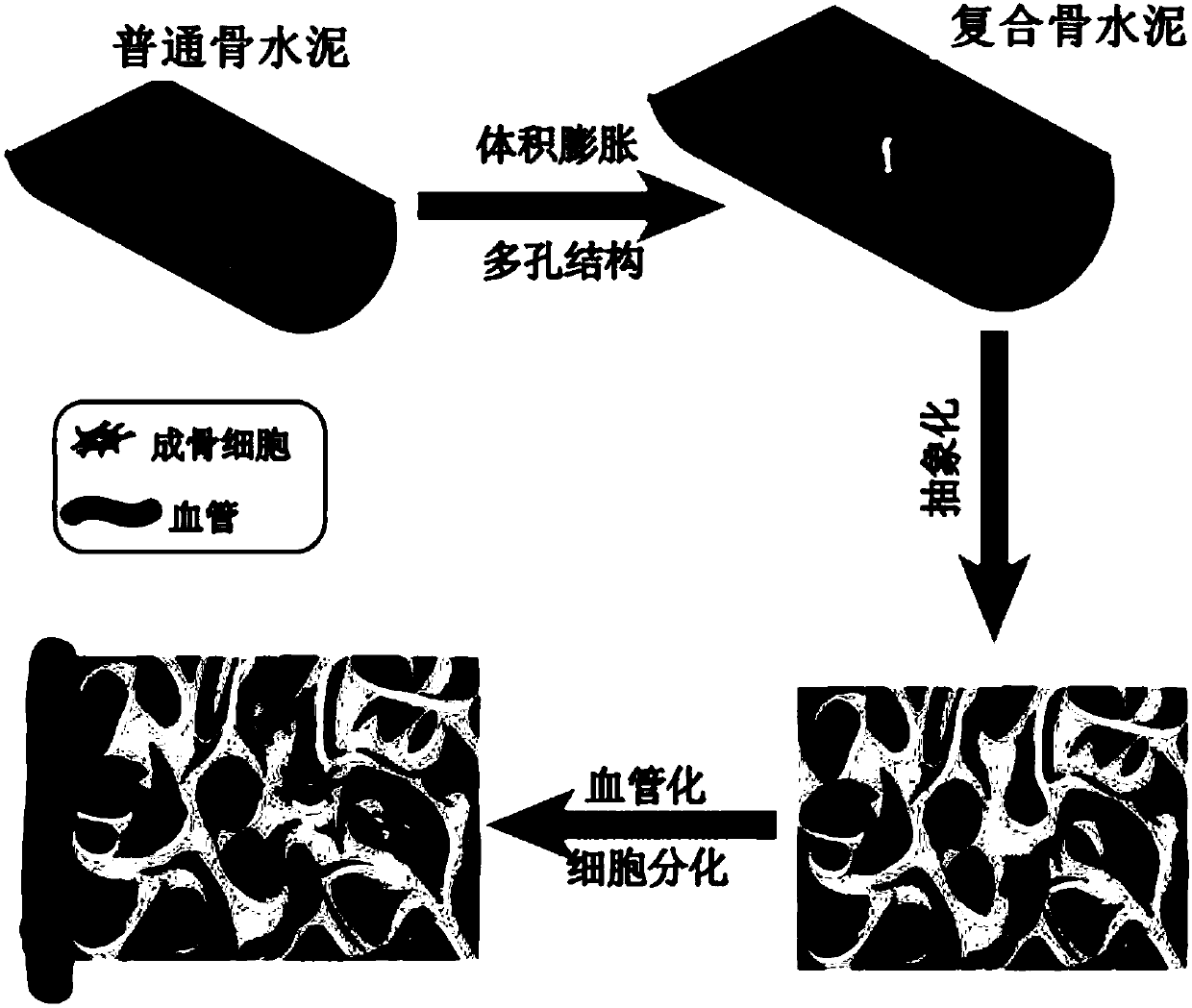

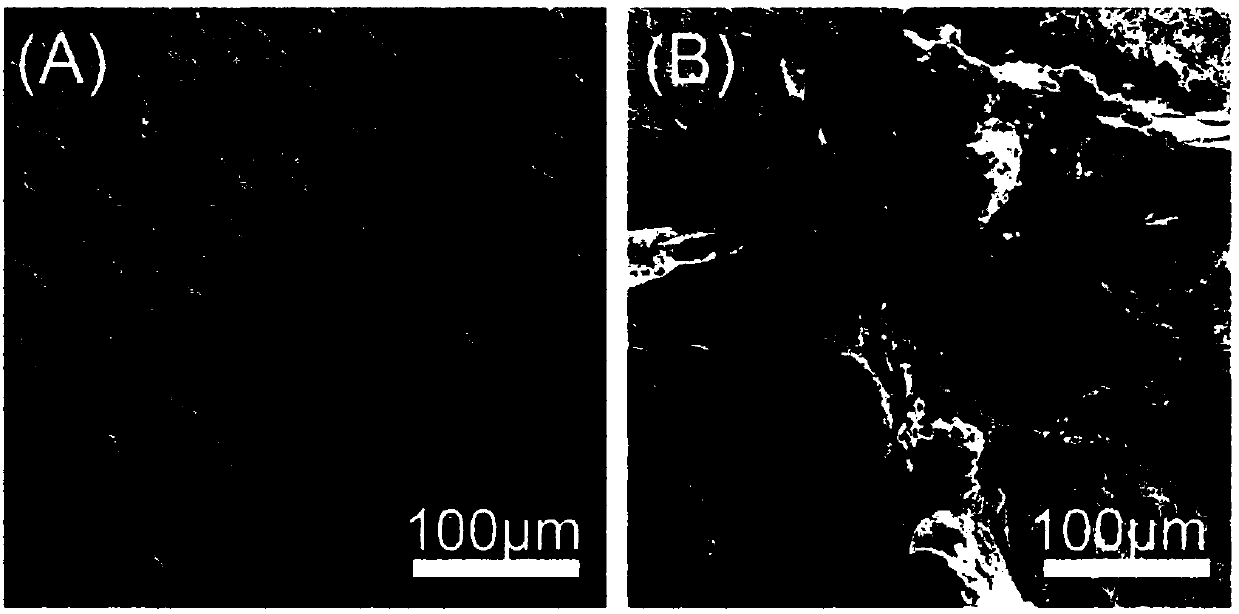

[0032] Such as Figure 1-Figure 3 As shown, the present invention provides an injectable expandable composite bone cement imitating a bone trabecular structure and a preparation method thereof. The injectable expandable bone cement has injectability, and can generate volume expansion during solidification and form a porous structure after solidification The high-quality bone cement can solve the problems of heat generation, high elastic modulus, volume shrinkage and other problems in the application of traditional bone cement, and it also has good biocompatibility and degradability.

[0033] Its preparation method is as follows:

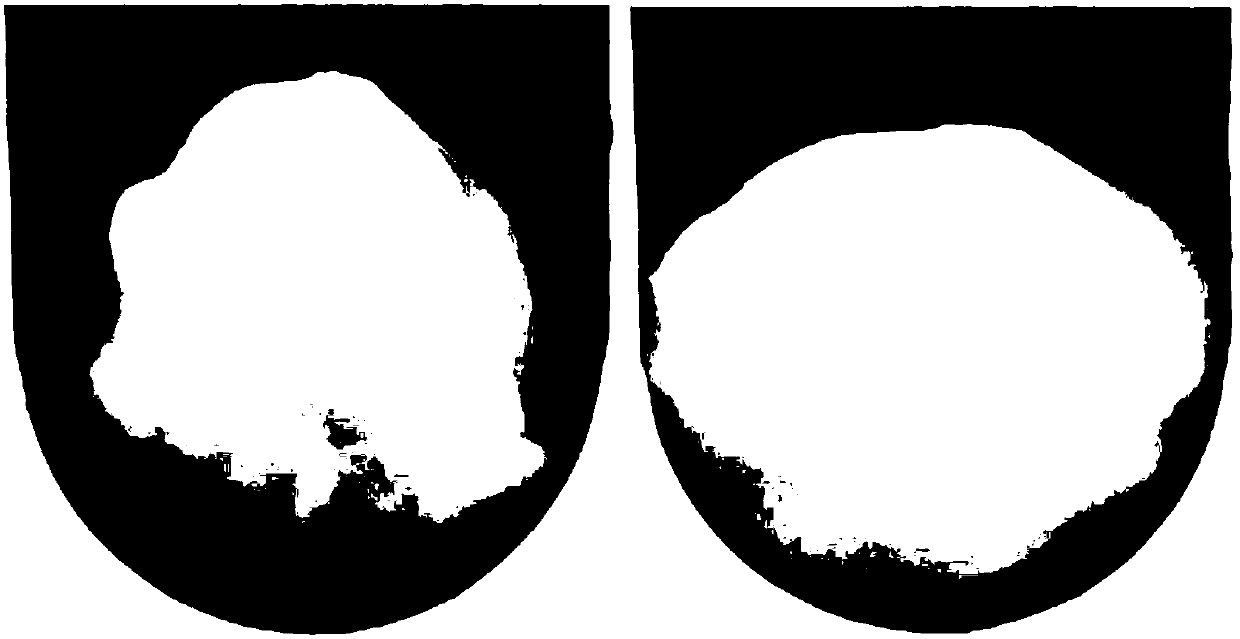

[0034] Mix the powder material and the expansion material evenly in a certain proportion, add a certain amount of curing liquid, and stir quickly to form a slurry; inject the formed slurry into the mold, and put the mold into a constant temperature and humidity box to cure for a certain period of time; after the curing is completed Demoulding to obt...

Embodiment 1

[0047] The powder material of the injectable expandable bone cement of the imitation bone trabecular structure of this embodiment is calcium sulfate hemihydrate powder with a volume fraction of 95%, and an expansion material with a volume fraction of 5%; the solidification liquid is deionized water, liquid-solid The ratio is 0.5 ml / g.

[0048] The expanded material in this implementation example is prepared according to the following steps: Mix polyvinyl alcohol with deionized water and stir to fully dissolve; The resulting polyvinyl alcohol solution is foamed to form bubbles of uniform size in the solution; Add crosslinking agent and catalyst to the foamed solution, and pour the solution into the mold; After molding, it is taken out from the mold, rinsed, dried and mechanically crushed into granules with a particle size of less than 1 mm.

[0049] The preparation steps of the injectable expansive bone cement imitating the bone trabecular structure are as follows:

[00...

Embodiment 2

[0054] The powder material of the injectable expandable bone cement of the imitation bone trabecular structure of this embodiment is calcium phosphate bone cement powder with a volume fraction of 90%, and an expansion material with a volume fraction of 10%; the solidification solution is a physiological saline solution, liquid-solid The ratio is 0.5 ml / g.

[0055] The expanded material in this implementation example is prepared according to the following steps: Mix polyvinyl alcohol with deionized water and stir to fully dissolve; The resulting polyvinyl alcohol solution is foamed to form bubbles of uniform size in the solution; Add crosslinking agent and catalyst to the foamed solution, and pour the solution into the mold; After molding, it is taken out from the mold, washed, dried and mechanically crushed into granules, and the particle size is less than 1 mm.

[0056] The preparation steps of the injectable expansive bone cement imitating the bone trabecular structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com