Bionic three-dimensional bone trabecula structure porous tantalum and preparation method thereof

A trabecular structure and bone trabecular technology, applied in the field of medical orthopedic bionic materials, can solve the problems of low porosity, high elastic modulus, poor strength, etc., to achieve the goal of promoting bone ingrowth and bone regeneration, and reducing stress shielding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a preparation method of the biomimetic three-dimensional trabecular bone structure porous tantalum according to the above technical scheme, which includes the following steps:

[0036] Use 3D printing to print the required three-dimensional trabecular bone structure;

[0037] Annealing the three-dimensional trabecular bone structure to obtain a bionic three-dimensional trabecular bone structure porous tantalum;

[0038] The annealing temperature is 900~1100℃, and the vacuum degree is less than 5×10 -3 Pa, time is 2~3h.

[0039] The present invention uses 3D printing to print the required three-dimensional trabecular bone structure.

[0040] In the present invention, the specific steps of using 3D printing to print the required three-dimensional trabecular bone structure preferably include:

[0041] A three-dimensional trabecular bone structure model is established through modeling software according to actual needs, and the three-dimensional tra...

Embodiment 1

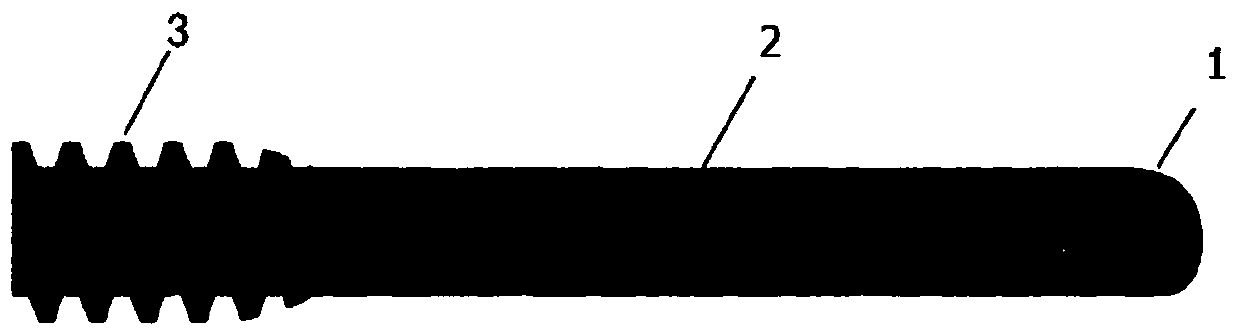

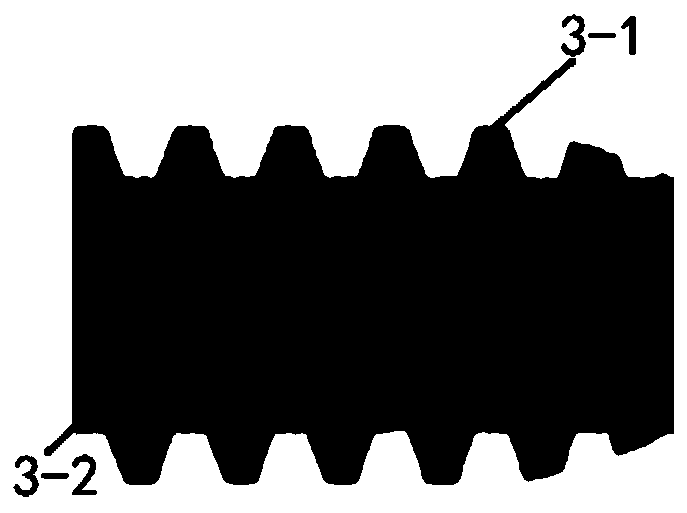

[0060] Example 1: Support rod-shaped bionic three-dimensional trabecular bone structure porous tantalum for treatment of femoral head necrosis

[0061] Determine the porous tantalum model of supporting rod-shaped bionic three-dimensional trabecular bone structure according to the actual situation of the patient. The specific structure is as follows figure 2 , image 3 with Figure 4 As shown; the supporting rod-shaped three-dimensional trabecular bone structure model is imported into the selected laser melting equipment, using a spherical tantalum powder with a diameter of 15-45 μm, under the conditions of a laser power of 250W, a scanning speed of 150mm / s, and a scanning distance of 0.07mm Print down to obtain a supporting rod-shaped three-dimensional trabecular bone structure;

[0062] After printing, take the printed product (substrate and supporting rod-shaped three-dimensional trabecular bone structure) out of the device, use a wet explosion-proof vacuum cleaner to suck up the...

Embodiment 2

[0068] Example 2: Reinforced block bionic three-dimensional trabecular bone structure porous tantalum for joint replacement revision

[0069] Determine the porous tantalum model of the reinforced block bionic three-dimensional trabecular bone structure according to the actual situation of the patient. The specific structure is as follows Figure 5 As shown; the reinforced block three-dimensional trabecular bone structure model is imported into the selected laser melting equipment, using a spherical tantalum powder with a diameter of 15 to 45 μm, at a laser power of 250W, a scanning speed of 150mm / s, and a scanning distance of 0.07mm Print under conditions to obtain a reinforced block 3D trabecular bone structure;

[0070] After printing, take the printed product (substrate and reinforced block three-dimensional trabecular bone structure) out of the equipment, use a wet explosion-proof vacuum cleaner to suck up the surface and internal residual powder of the printed product; use dry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com