Hysteresis control method based on two-step method

A technology of hysteresis control and footwork, applied in the direction of valve operation/release device, valve details, engine components, etc., can solve problems such as unsatisfactory compensation effect, many compensation control parameters, and difficult adjustment, and achieve good operation effect , fewer control parameters, clear physical meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0031] Founded in 1974, OPTO22 is mainly involved in the development and manufacture of hardware and software products in the fields of industrial automation, remote monitoring and enterprise data acquisition. Using standard and commercial Internet, networking and computer technologies, OPTO22's input / output and control systems allow customers to monitor, control and collect data on all mechanical, electrical and electronic assets.

[0032] The present invention develops real-time monitoring and control software based on OPTO22PAC Project Professional. PAC Project Professional includes the following parts: PAC Control, PAC Display, OPTO OPC Server, PAC Manager, etc. The algorithm is programmed with PAC Control script language, and the user monitoring interface is developed with PAC Display.

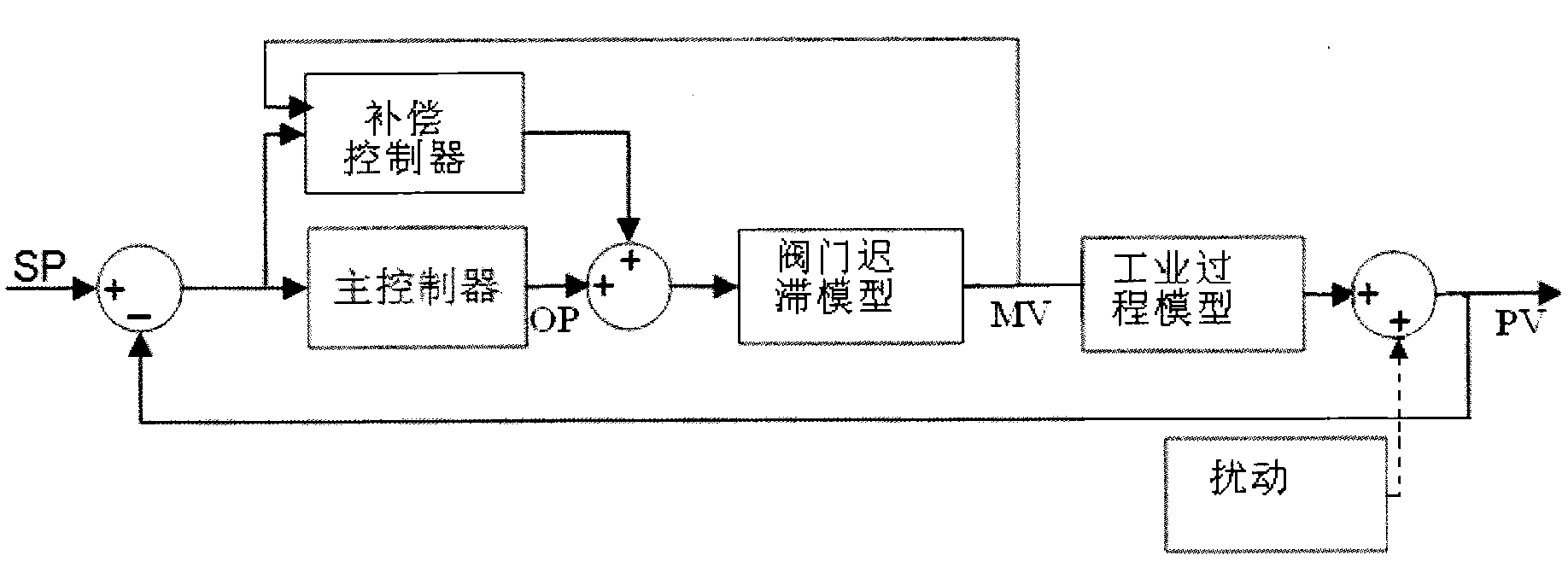

[0033] figure 1 Shown is a kind of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com