Light-emitting diode display back plate, manufacturing method and display device for light-emitting diode display back plate

A technology of light-emitting diodes and display backplanes, applied in the field of display devices, light-emitting diode display backplanes and manufacturing methods thereof, can solve problems such as unfavorable large-scale production, increased equipment investment, and increased manufacturing costs of light-emitting diode display backplanes. Effects that improve the glow quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

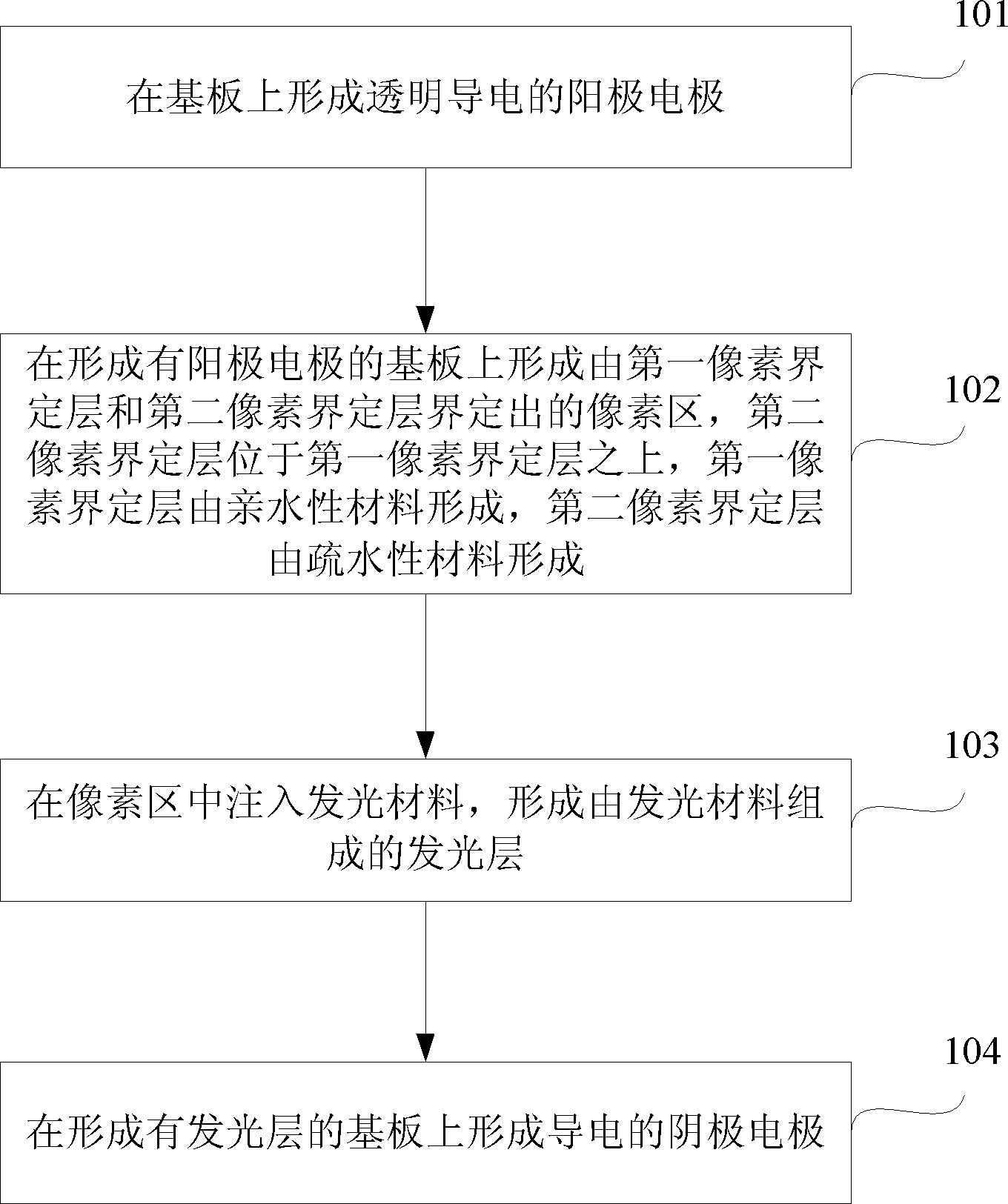

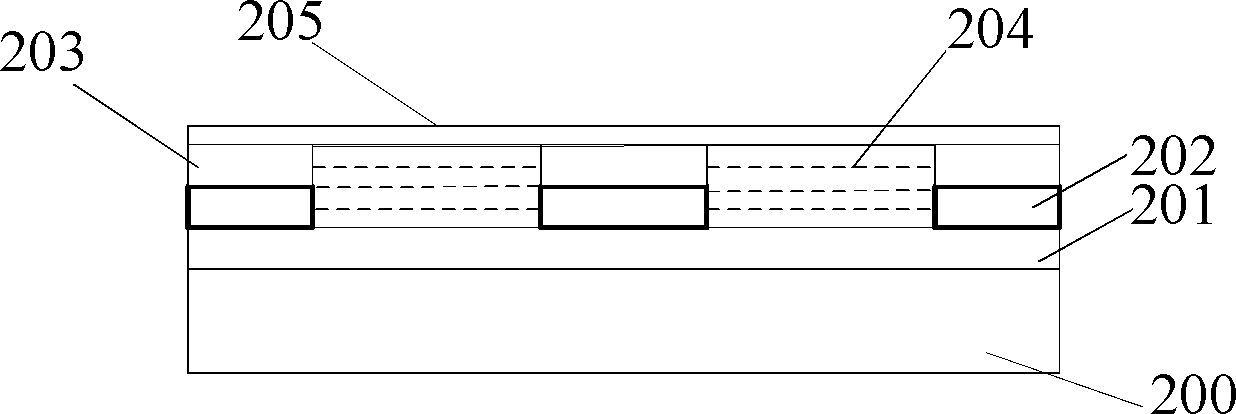

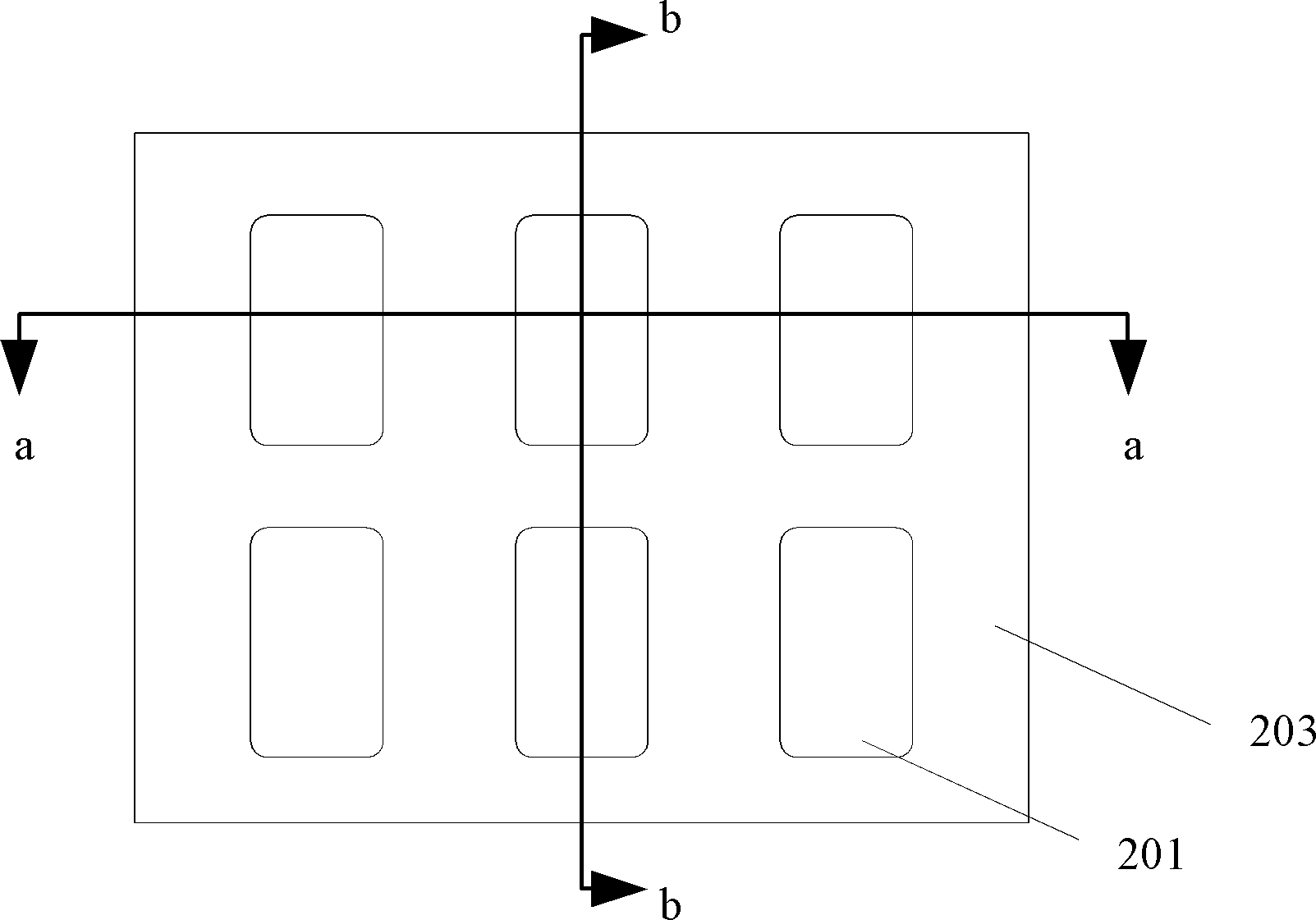

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the embodiments of the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0039] The embodiments of the present invention aim at fluorinating the surface of the PDL layer in the prior art in order to ensure that the printed droplets smoothly and evenly cover the pixel area defined by the pixel defining layer and prevent the droplets from flowing to adjacent pixel areas. treatment, thereby improving the wetting characteristics of the surface of the PDL layer, but this method needs to increase the investment in equipment, increases the manufacturing cost of the light-emitting diode display backplane, and is not conducive to the problem of mass production. A light-emitting diode display backplane and its The manufacturing method and the display device enable the luminescent material to be flatly spread on the LE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com