Combined automatic air drying and balancing device for sample preparation

An air drying and balancing device technology, which is applied in the direction of non-progressive dryers, static material dryers, local stirring dryers, etc., can solve the problems of heavy manual labor, easy sample mixing, and manual memory required for drying and balancing time, etc. problems, to achieve the effect of improving drying and balancing efficiency, increasing the degree of automation, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

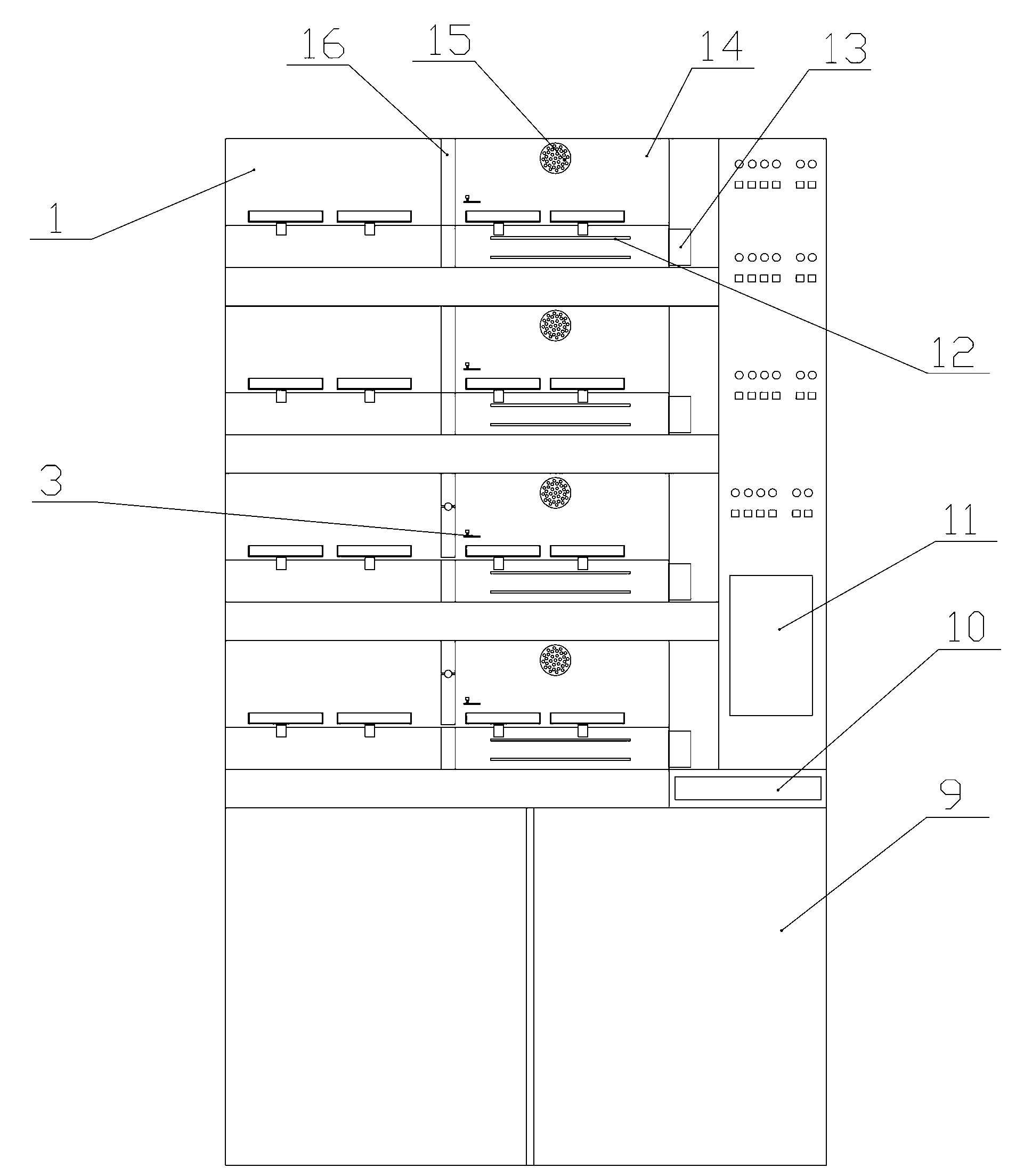

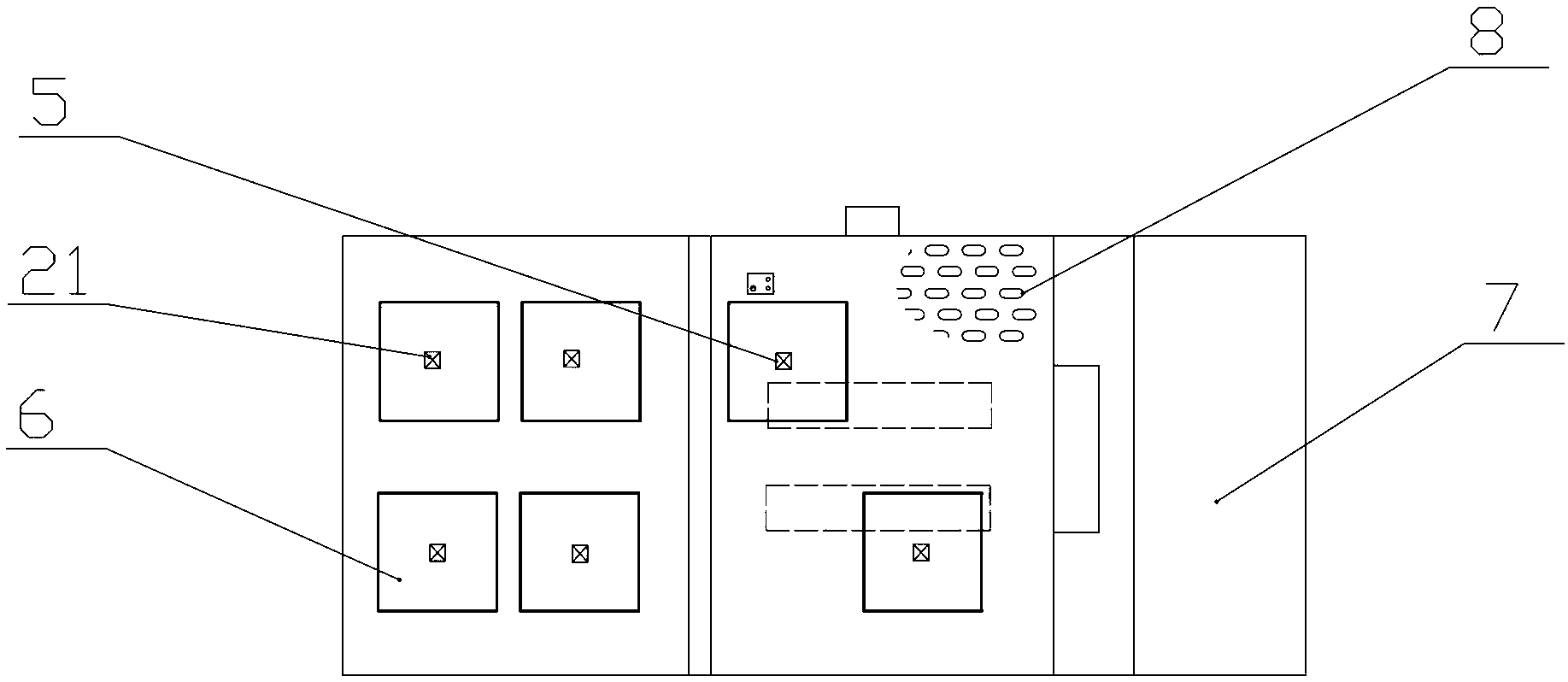

[0027] Embodiment 1: as figure 1 and figure 2 As shown, the combined automatic air drying balance device for sample preparation of the present invention includes more than one drying balance assembly and a control box 7, and each drying balance assembly includes a side-by-side arrangement and is separated by a middle partition 16. The air balance box 1 and the heating and drying box 14; the heating and drying box 14 is relatively closed, and the heating and drying box 14 is provided with a heating sheet 12 and a measurement and control element 3, which has the function of heating / heating constant temperature, and the temperature is controllable; each group of heating and drying boxes 14 all adopt the mode of heating and controlling temperature with independent heating chip 12, and carry out temperature measurement and monitoring with measurement and control element 3. The heating and drying box 14 is provided with an air inlet 13 and an air outlet 15, the air inlet 13 is loc...

Embodiment 2

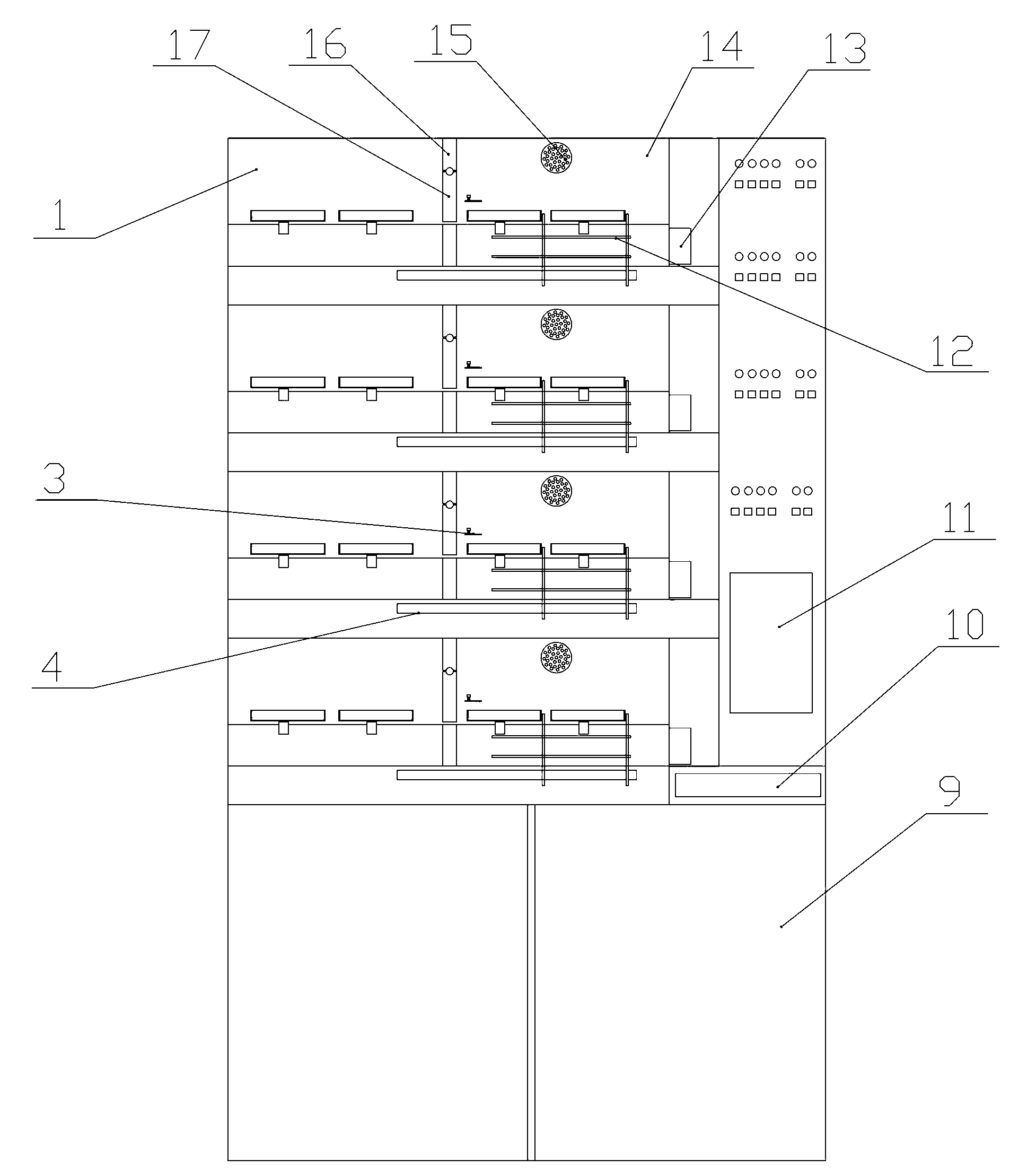

[0032] Embodiment 2: as image 3 and Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that this embodiment is further used to move the sample tray 6 from the heating drying box 14 to the sample transfer assembly 4 of the air balance box 1 . When the heating and drying time of the sample tray 6 is up, the qualified sample tray 6 can be automatically pushed into the air balance box 1 by the sample transfer component 4 .

[0033] In this embodiment, a movable door 17 is hinged on the middle partition 16. When the sample tray 6 moves under the driving of the sample transfer assembly 4, the sample tray 6 can push the movable door 17 to turn over. After the sample tray 6 passes through, the movable door 17 and reliable dead weight self-closing. It can be understood that the dodge door 17 can also be driven by means or mechanisms such as electric, pneumatic, magnetic and hydraulic, and is controlled by the control...

Embodiment 3

[0036] Embodiment 3: as Figure 5As shown, the structure of this embodiment is basically the same as that of Embodiment 2, and the difference is that: this embodiment is further provided with a dehumidification assembly 2, a first The valve 18 and the second valve 19 form a closed cycle of the gas circuit. After the air flow passes through the air inlet 13, it passes through the heating plate 12 to bring the hot air upward from the air-permeable interlayer 8 into the heating chamber, and the water vapor is brought out from the upper air outlet 15, and the air flow with water flow enters the dehumidification component 2, after removing the moisture The dry air flow flows into the heating drying box 14 from the air inlet 13 again.

[0037] The dehumidification assembly 2 can be equipped with multiple sets of drying balance assemblies, and can be connected to the drying balance assembly in working or non-working state through the control of the first valve 18 and the second valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com