Loading test device and method of asymmetric lateral-force-resisting structure

A loading test device, asymmetrical technology, applied in the direction of measuring device, using repeated force/pulsation force to test material strength, instrument, etc., can solve the problem of unreasonable control of horizontal loading and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

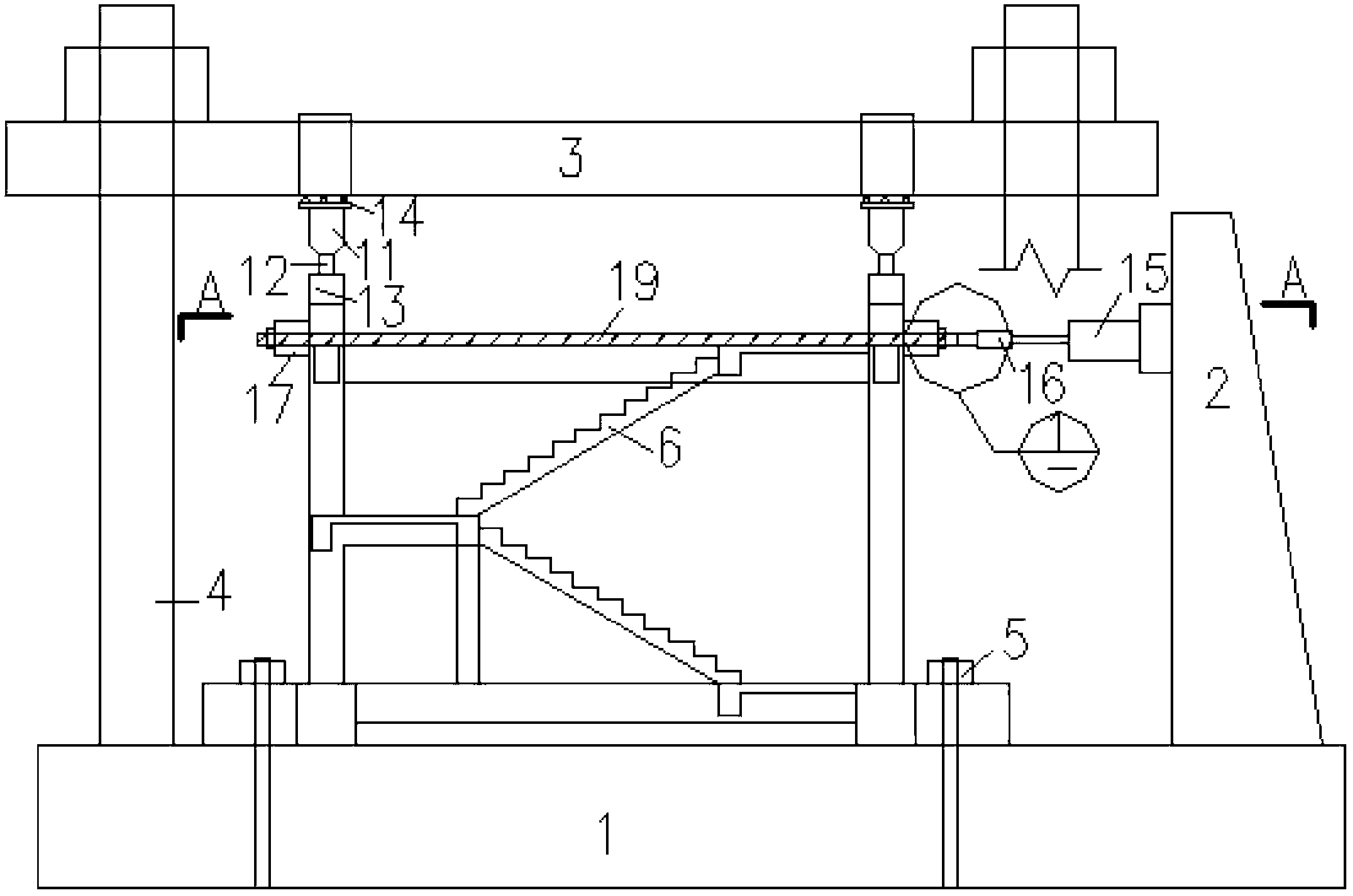

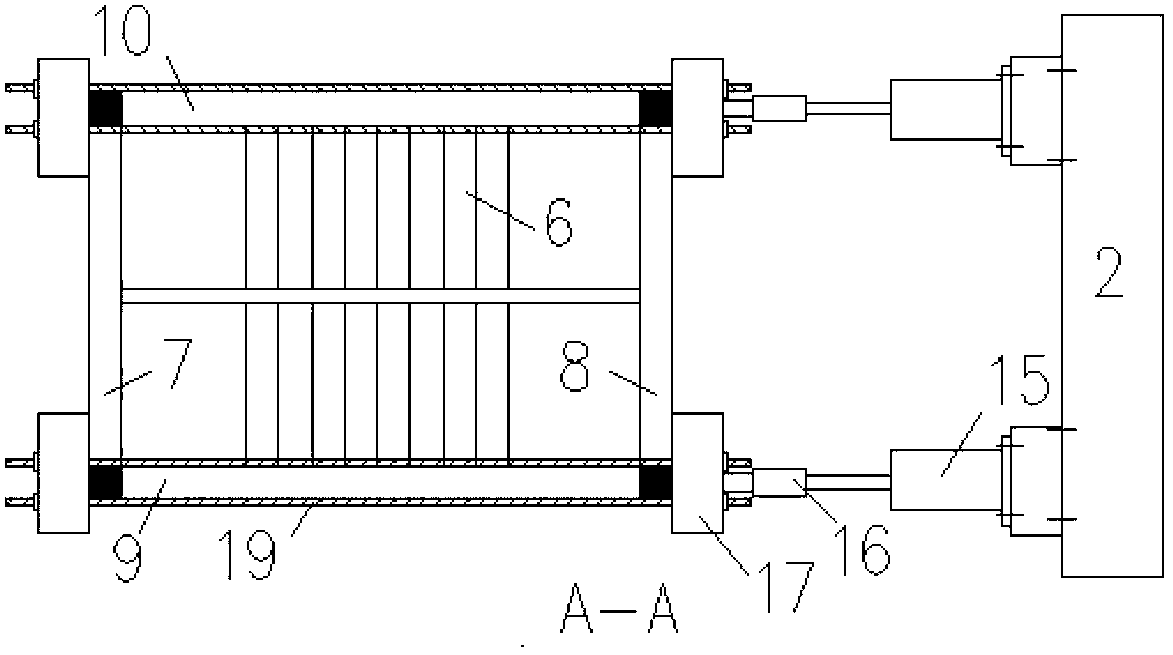

[0026] The structure to be tested in this embodiment is the stairwell substructure test piece 6 .

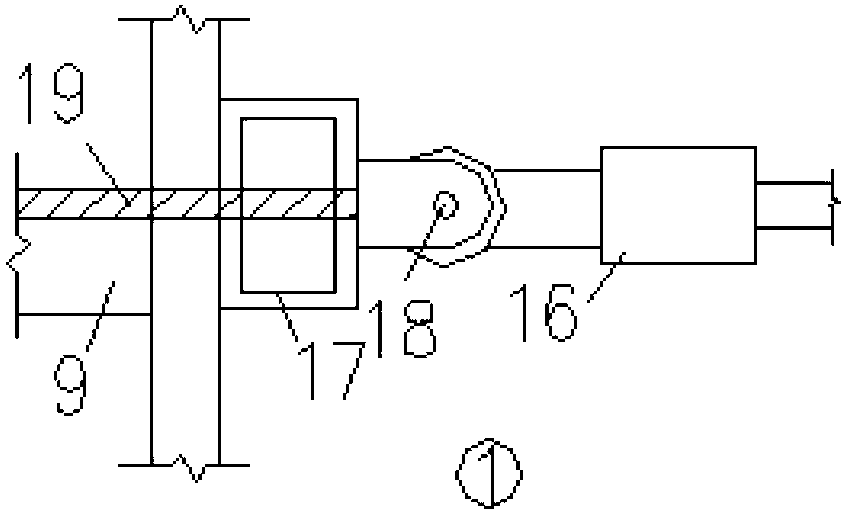

[0027] When it is used as a quasi-static test of the reinforced concrete frame stairwell substructure under the reciprocating action of horizontal force, the loading device is as follows: figure 1 As shown, it consists of a load-bearing system, a front vertical loading system, a rear vertical loading system, a left horizontal loading system, and a right horizontal loading system. The bearing system is divided into a pedestal 1, a reaction wall 2 on the right side of the pedestal 1, a bracket 4 fixed on the pedestal 1, and a reaction beam 3 fixed on the upper part of the bracket 4. The front end vertical loading system is mainly composed of a vertical force jack 11 , a vertical force sensor 12 , a vertical load distribution beam 13 and a horizontal sliding support 14 . The vertical force jack 11 is arranged above the two column tops of the front frame 7 outside the horizontal lo...

Embodiment 2

[0041] The structure to be tested in this embodiment is a substructure test piece 20 composed of a frame and an infill wall frame.

[0042] When the substructure composed of frame and infill wall frame is subjected to quasi-static test under the reciprocating action of horizontal force, the loading device is as follows: Figure 4 As shown, it consists of a load-bearing system, a front vertical loading system, a rear vertical loading system, a left horizontal loading system, and a right horizontal loading system. The bearing system is divided into a pedestal 1, a reaction wall 2 on the right side of the pedestal 1, a bracket 4 fixed on the pedestal 1, and a reaction beam 3 fixed on the upper part of the bracket 4. The front end vertical loading system is mainly composed of a vertical force jack 11 , a vertical force sensor 12 , a vertical load distribution beam 13 and a horizontal sliding support 14 . The position of the vertical force jack 11 corresponds to the top position o...

Embodiment 3

[0055] The structure to be tested in this embodiment is a concrete frame substructure specimen 22 with a steel support on one side.

[0056] When used as a pseudo-static test of a frame structure with steel supports on one side under the reciprocating action of a horizontal force, the loading device is as follows: Figure 6As shown, it consists of a load-bearing system, a front vertical loading system, a rear vertical loading system, a left horizontal loading system, and a right horizontal loading system. The bearing system is divided into a pedestal 1, a reaction wall 2 on the right side of the pedestal 1, a bracket 4 fixed on the pedestal 1, and a reaction beam 3 fixed on the upper part of the bracket 4. The front end vertical loading system is mainly composed of a vertical force jack 11 , a vertical force sensor 12 , a vertical load distribution beam 13 and a horizontal sliding support 14 . The position of the vertical force jack 11 corresponds to the top position of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com