Photodiode and method for improving full-trap capacity and quantum efficiency of image sensor

A photodiode and image sensor technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the detectable light intensity range, dynamic range, signal-to-noise ratio and sensitivity, and deteriorating imaging quality, etc. The effect of electron transfer, increasing quantum efficiency, and increasing full well capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

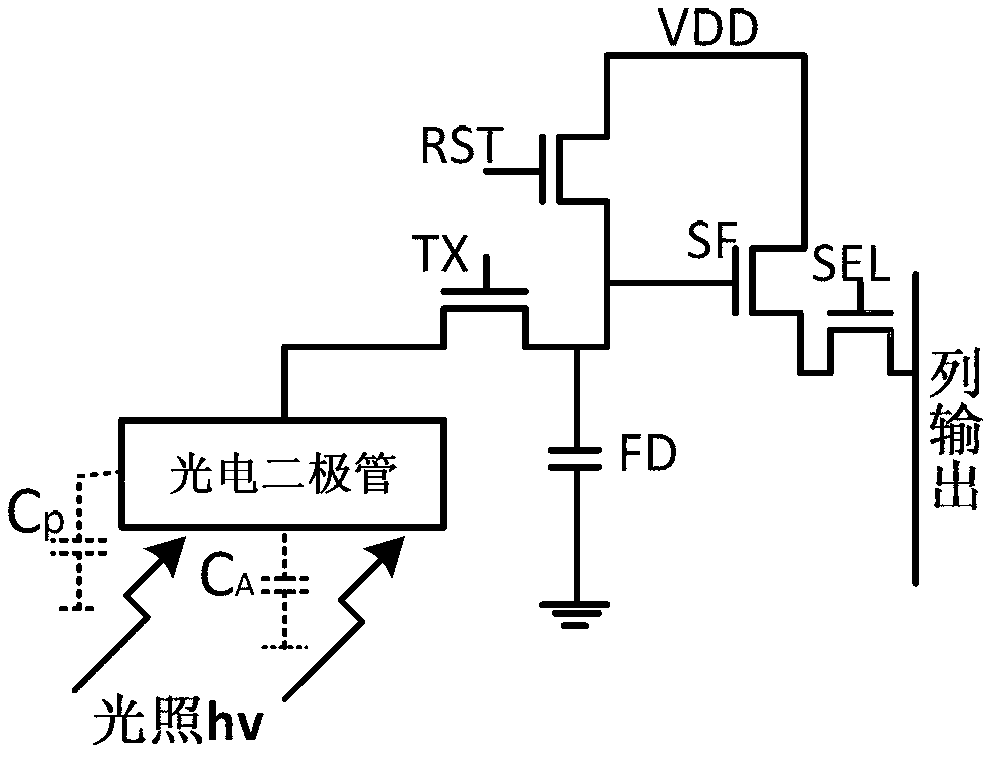

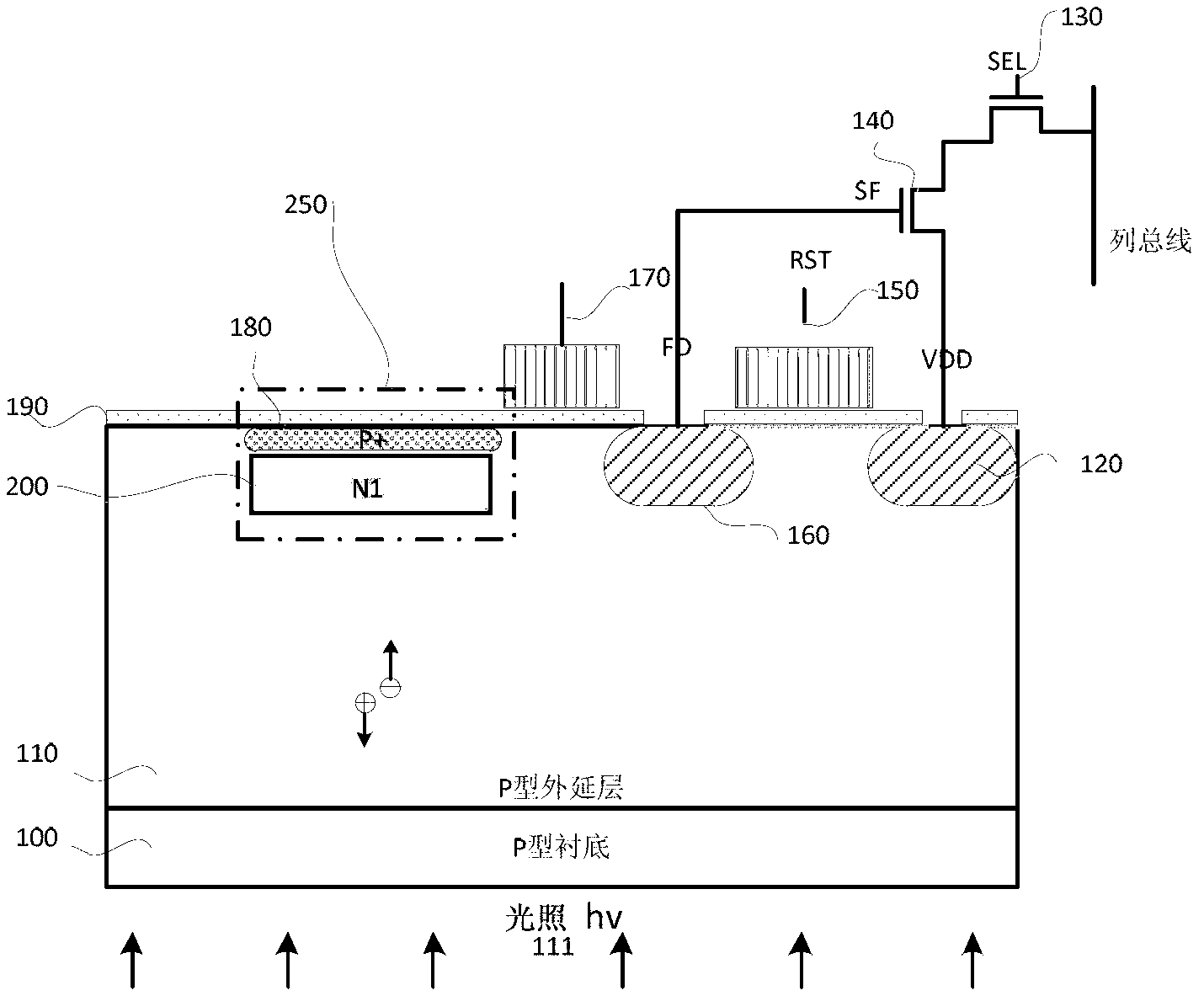

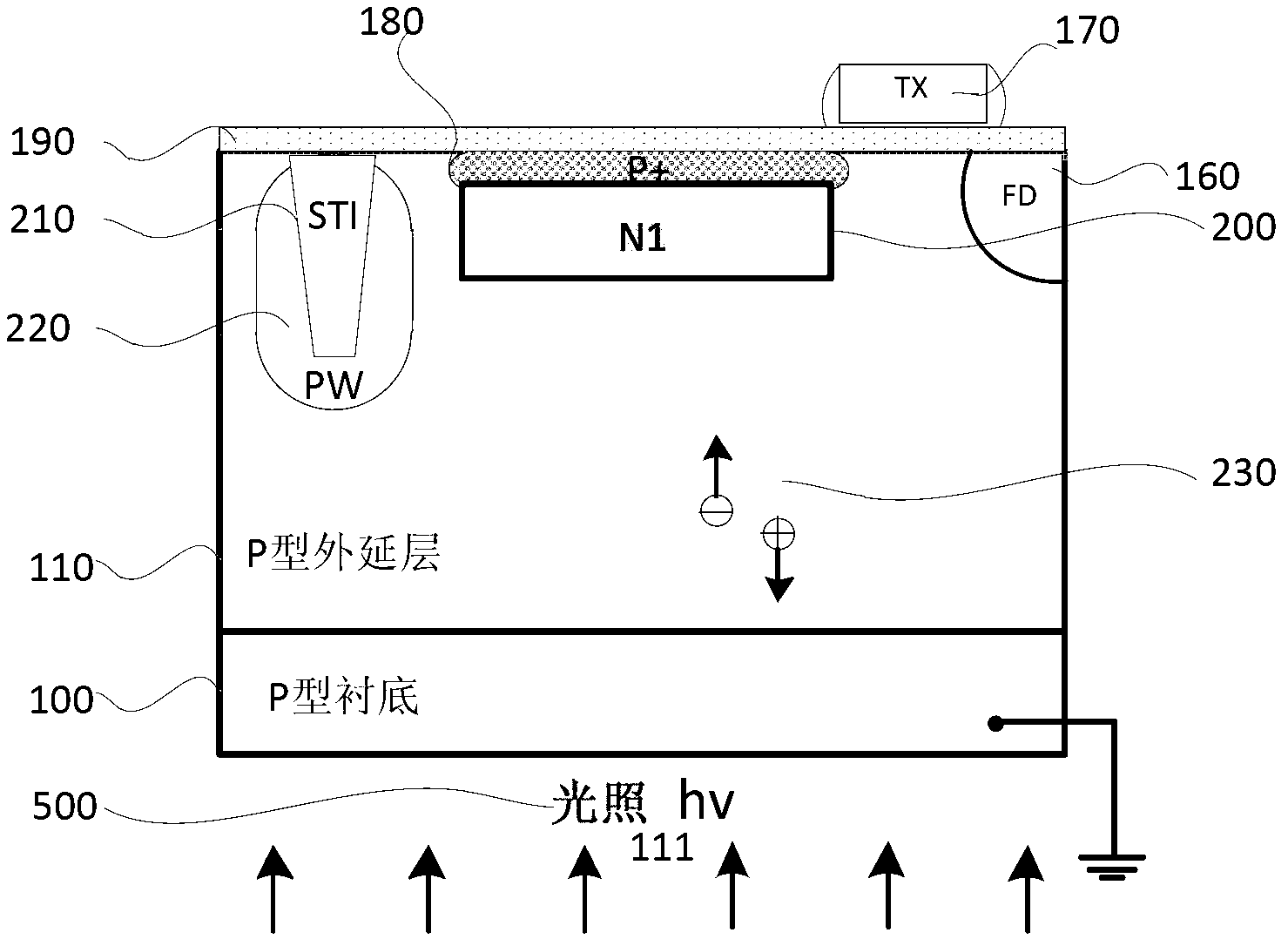

[0023] The invention relates to an optimized structure of a photodiode (PD), which can enable small-sized pixels to achieve higher full-well capacity without degrading image tailing of pixel units.

[0024] In the traditional back-illuminated clamped photodiode (PPD) structure, the N-buried layer 200 of the photodiode is realized by one-step N-type doping, such as figure 1 shown. With the shrinking of pixel size, the photodiode area of a single pixel is also decreasing, and the area of the N buried layer will be reduced accordingly. If this structure is still used, it will not be able to provide sufficient full well capacity for the pixel unit. And if in order to increase the full well capacity, only increase the implantation energy of the N buried layer 200 to make the N buried layer with a deeper vertical depth attempt to increase the full well capacity, this will make the N buried layer lack obvious vertical concentration gradient, causing far away Electrons inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com