Folded and assembled battery and preparation method thereof

An assembled battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of battery cell reaction degree, uneven rate, unsuitable for the promotion of large-capacity batteries, and uneven internal structure of the winding core. Achieve the effect of uniform structure, high production efficiency and easy control of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

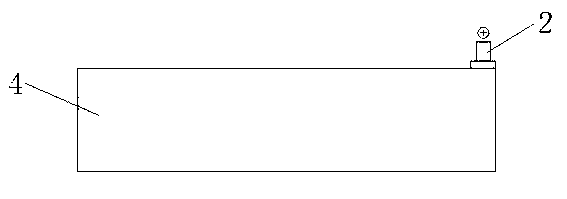

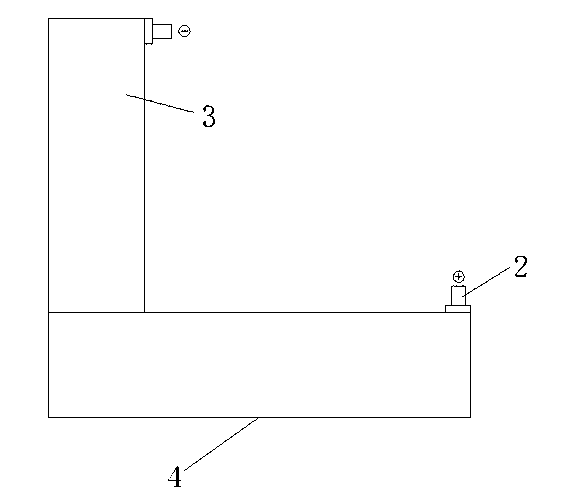

[0031] Such as Figure 1~4 As shown, a folded sheet assembled battery includes a winding core body 1, an aluminum-plastic film for wrapping the winding core body 1 and an electrolyte injected into the aluminum-plastic film, and the winding core body 1 includes a positive electrode sheet 2 , a negative electrode sheet 3 and a separator 4, the separator 4 covers the positive electrode sheet 2 after being folded in half, and the positive electrode sheet 2 and the negative electrode sheet 3 are folded and assembled. Specifically, the separator 4 is folded in half laterally to cover the positive electrode sheet 2, which is easy to operate.

[0032] The positive electrode sheet 2 and the negative electrode sheet 3 described in this embodiment are folded and assembled alternately in sequence. When folding and assembling, the positive electrode sheet 2 is folded in the direction of the negative electrode sheet 3, and then the negative electrode sheet 3 is folded in the direction of th...

Embodiment 2

[0037] The difference between this embodiment and Embodiment 1 lies in that there are two or more folding layer groups in this embodiment. The winding core body 1 of this embodiment is thicker and has a larger capacity, and can be made into an ultra-thick battery.

[0038] Features that are not explained in this embodiment are explained in Embodiment 1, and will not be repeated here.

preparation Embodiment 1

[0040] A method for preparing the folded sheet assembled battery of Example 1, comprising the following preparation steps:

[0041] (a) After the diaphragm 4 is folded in half, the positive electrode sheet 2 is placed in the space formed by the diaphragm 4 folded in half, and the diaphragm 4 covers the positive electrode sheet 2;

[0042] (b) placing the negative electrode sheet 3 on the surface of the separator 4 so that the negative electrode sheet 3 is perpendicular to the positive electrode sheet 2;

[0043] (c) The positive electrode sheet 2 and the negative electrode sheet 3 are folded and assembled to obtain the roll core body 1;

[0044] (d) Wrap the roll core body 1 with an aluminum-plastic film, and inject electrolyte into the aluminum-plastic film to obtain a folded sheet assembled battery.

[0045] The folding assembly is specifically: the positive electrode sheet 2 is folded in half along the negative electrode sheet 3 , and then the negative electrode sheet 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com