LED (light emitting diode) light source subregion subsection transformation input driving control method and control circuit thereof

A technology of LED light source and control circuit, applied in the direction of light source, electric light source, energy-saving control technology, etc., can solve the problems of low light efficiency of lamps, different working hours of LED light-emitting tubes, low conversion efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

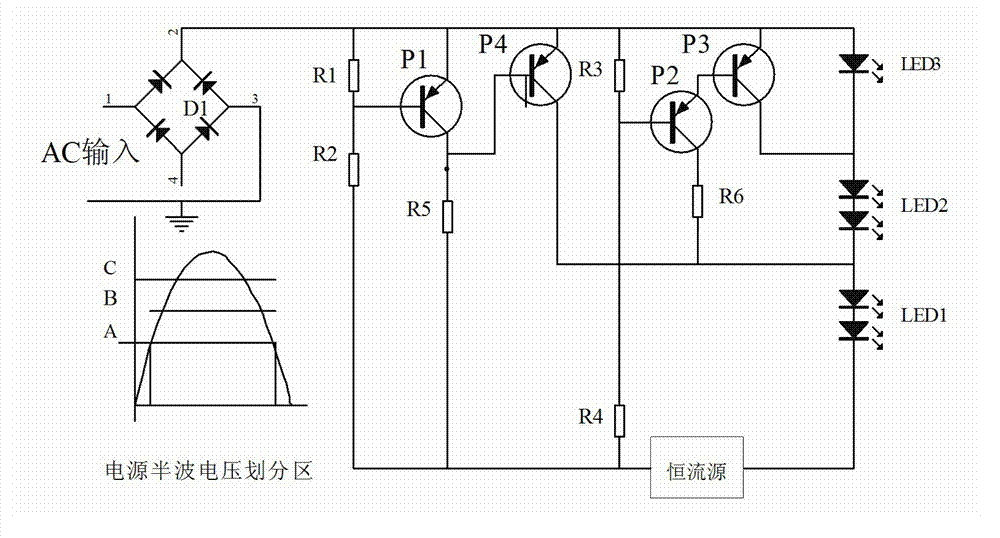

[0058] Embodiment 1: The LED light source of the present invention is partitioned and segmented into drive control methods. For 3 to 7 groups of LED light-emitting units with different conduction voltages, the conduction voltage of each group of LED light-emitting units is proportional. The LED light-emitting units In series and connected to the output terminal of the rectifier circuit through a constant current source circuit, the drive control method described above, 1) divides the output voltage of the rectifier circuit into 2 to 5 regions according to the waveform through the partition conversion input control circuit, and divides the high conduction voltage 2 to 6 groups of LED light-emitting units, according to the position of the region where the conduction voltage is located, the above-mentioned LED light-emitting units are driven in parallel, in series, or in series and parallel through the control circuit;

[0059]2) Combining with each of the above-mentioned division...

Embodiment 2

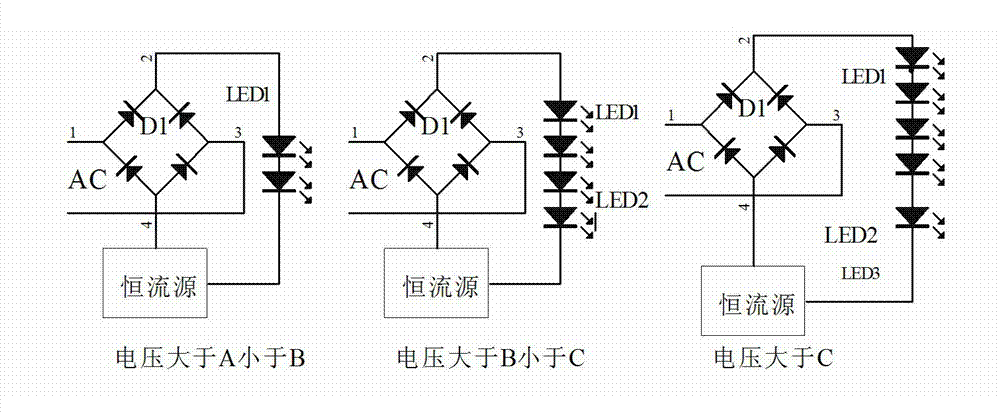

[0061] Embodiment 2: The driving control method of the LED light source in this embodiment is partitioned and segmented, and includes three groups of LED light emitting units, wherein the working voltage of the first group and the second group is 2u, and the working voltage of the third group is u. The half-wave cycle, partition conversion input control circuit is divided into 2 areas according to the instantaneous output voltage waveform of the rectifier circuit, and the segmental conversion input control circuit in the area divides each area into 2 sub-areas, and the LED light-emitting unit is controlled by the following method input,

[0062] 1) When the instantaneous output voltage of the rectifier circuit is less than 2u, all LED light-emitting units are not switched on;

[0063] 2) When the instantaneous output voltage of the rectifier circuit is greater than 2u but less than 3u, only the first group of LED light-emitting units is used;

[0064] 3) When the instantaneou...

Embodiment 3

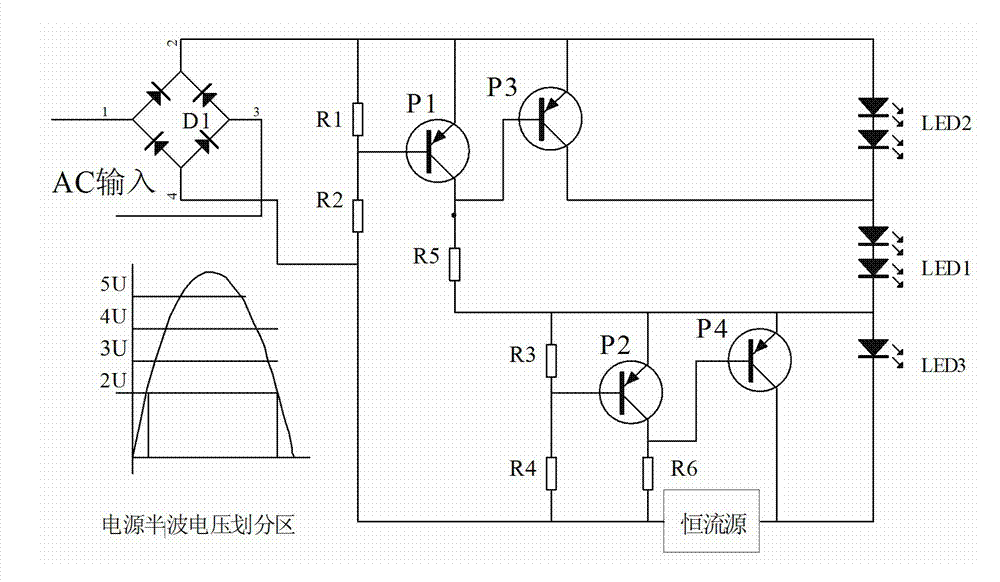

[0067] Embodiment 3: The LED light source of this embodiment is partitioned and segmented into drive control methods. The difference from Embodiment 2 is that on the basis of the method of Embodiment 2, the LED light-emitting units of the first group and the second group are passed through the unidirectional diode. connected, in each half-wave cycle, the subregional conversion input control circuit is divided into 2 regions according to the instantaneous output voltage waveform of the rectifier circuit, and the segmental conversion input control circuit in the region divides each region into 2 subregions, the same as described The partition conversion input control circuit is provided with a series-parallel conversion switch circuit, and the input of the LED light-emitting unit is controlled by the following method,

[0068] 1) When the instantaneous output voltage of the rectifier circuit is greater than 2u but less than 3u, the first group and the second group of LED light-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com